浙江农业学报 ›› 2025, Vol. 37 ›› Issue (12): 2615-2624.DOI: 10.3969/j.issn.1004-1524.20241088

党参种子丸粒化包衣性能仿真与试验

- 1.甘肃农业大学 机电工程学院,甘肃 兰州 730070

2.国家种子加工装备工程技术研究中心,甘肃 兰州 730070

-

收稿日期:2024-12-13出版日期:2025-12-25发布日期:2026-01-09 -

作者简介:朱高烁(2000—),男,湖北襄阳人,硕士研究生,研究方向为农业工程技术与装备。E-mail:550079078@qq.com -

通讯作者:*高爱民,E-mail:Gam0624@163.com -

基金资助:甘肃农业大学横向项目(GSAU-JSZR-2024-004)

Simulation and experiment on pelleting coating performance of Codonopsis pilosula seeds

ZHU Gaoshuo1( ), GAO Aimin1,*(

), GAO Aimin1,*( ), LI Baicheng2, LIU Kangkang1

), LI Baicheng2, LIU Kangkang1

- 1. Mechanical and Electrical Engineering College, Gansu Agricultural University, Lanzhou 730070, China

2. National Seed Processing Equipment Engineering Technology Research Center, Lanzhou 730070, China

-

Received:2024-12-13Online:2025-12-25Published:2026-01-09

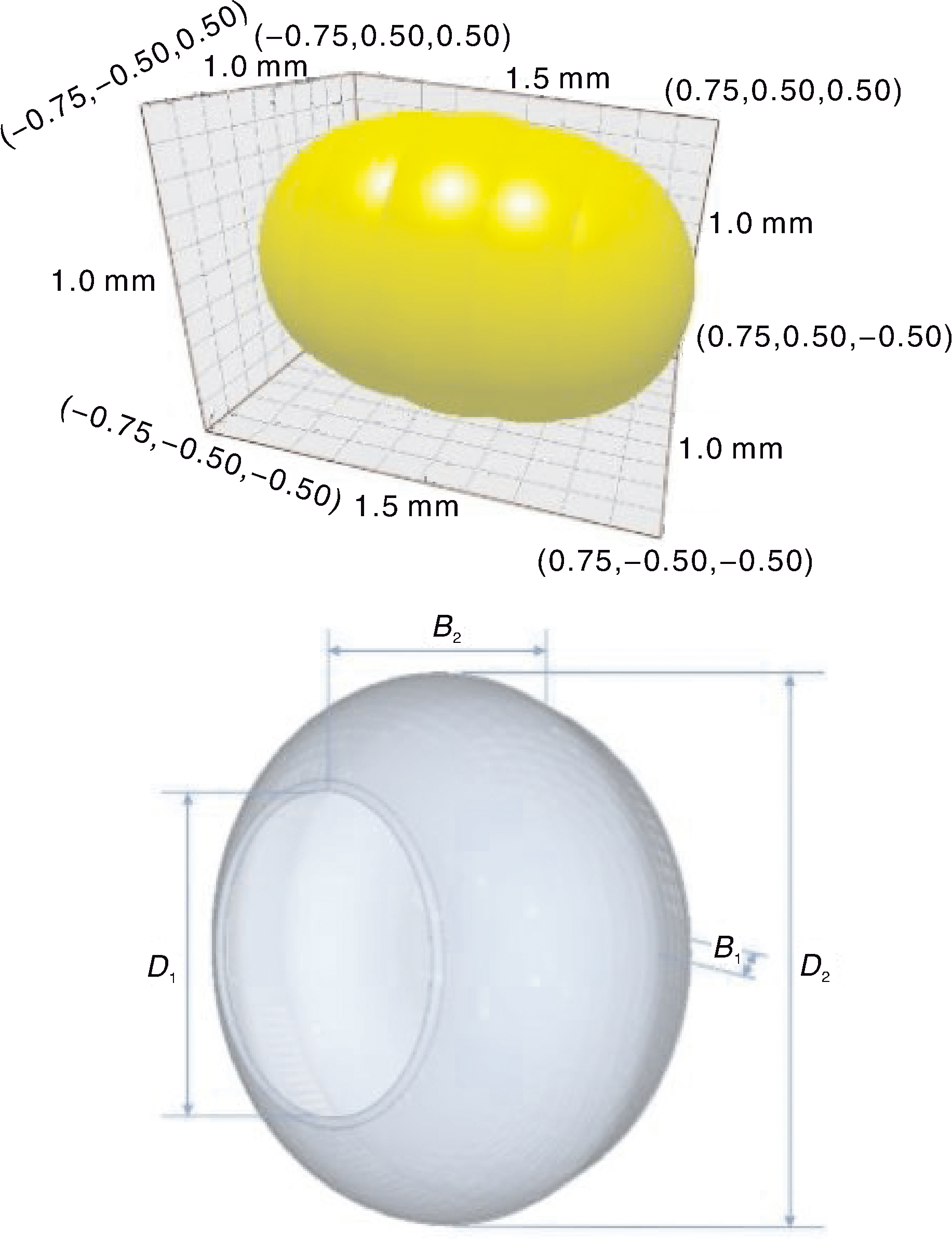

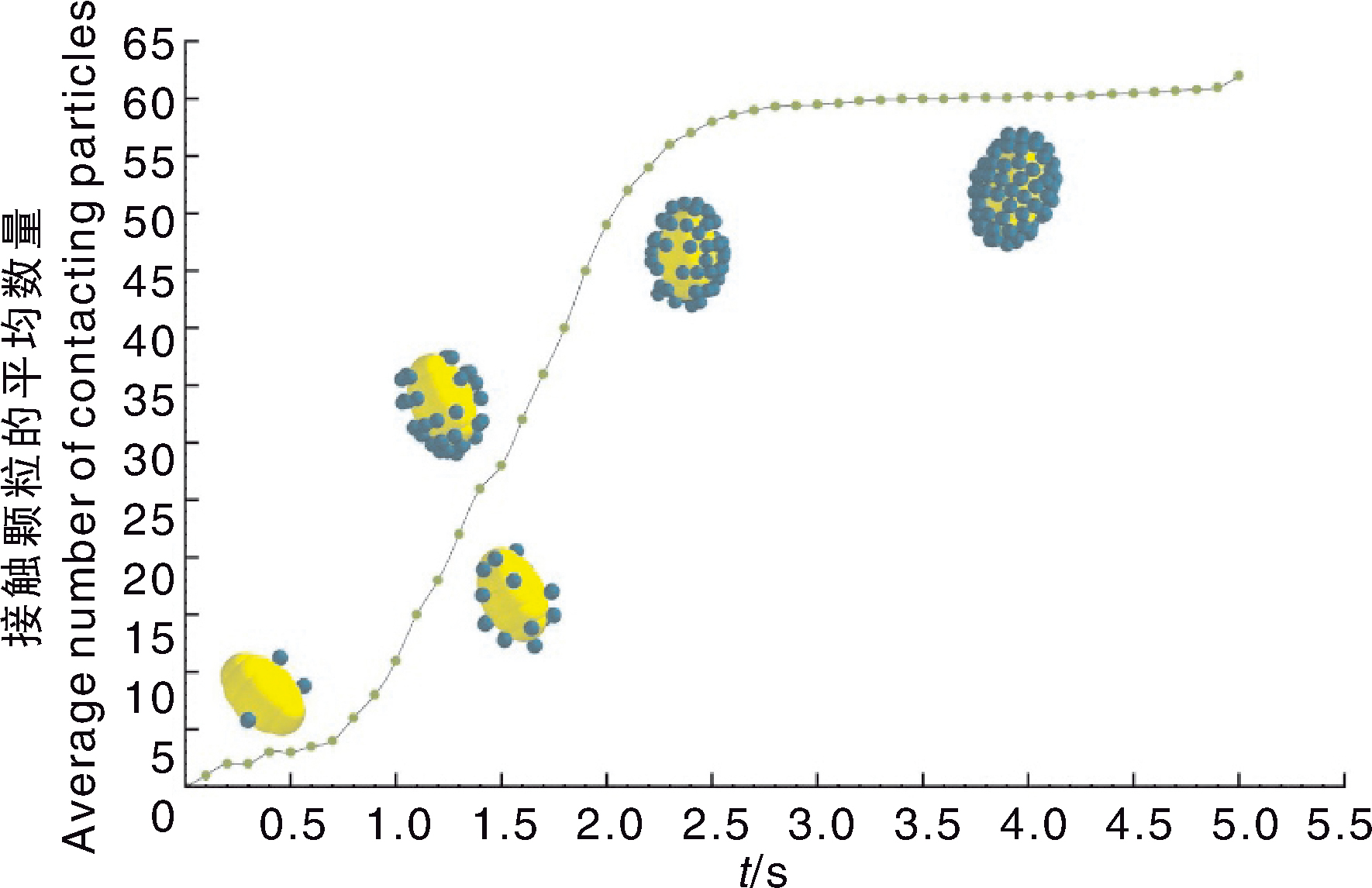

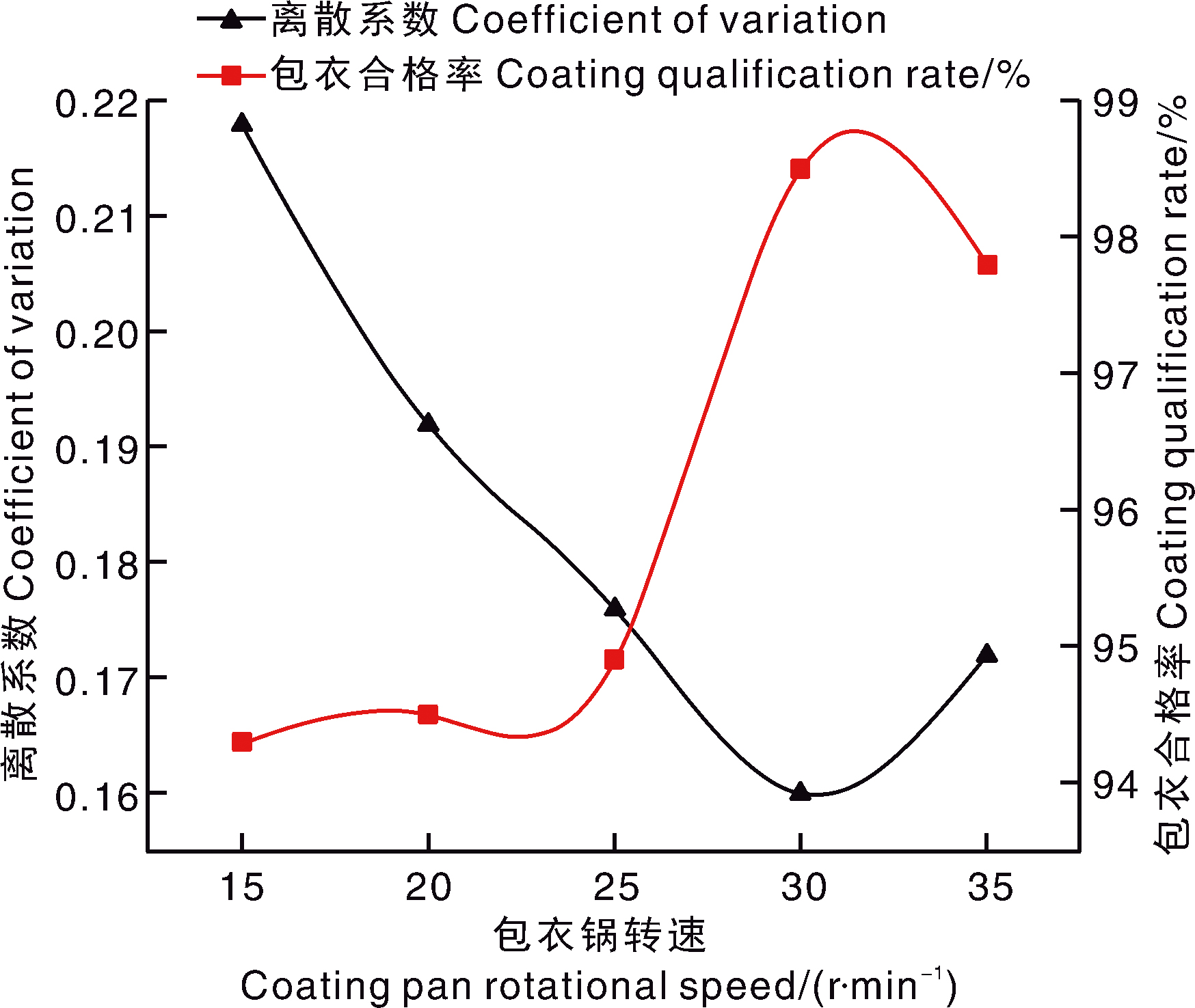

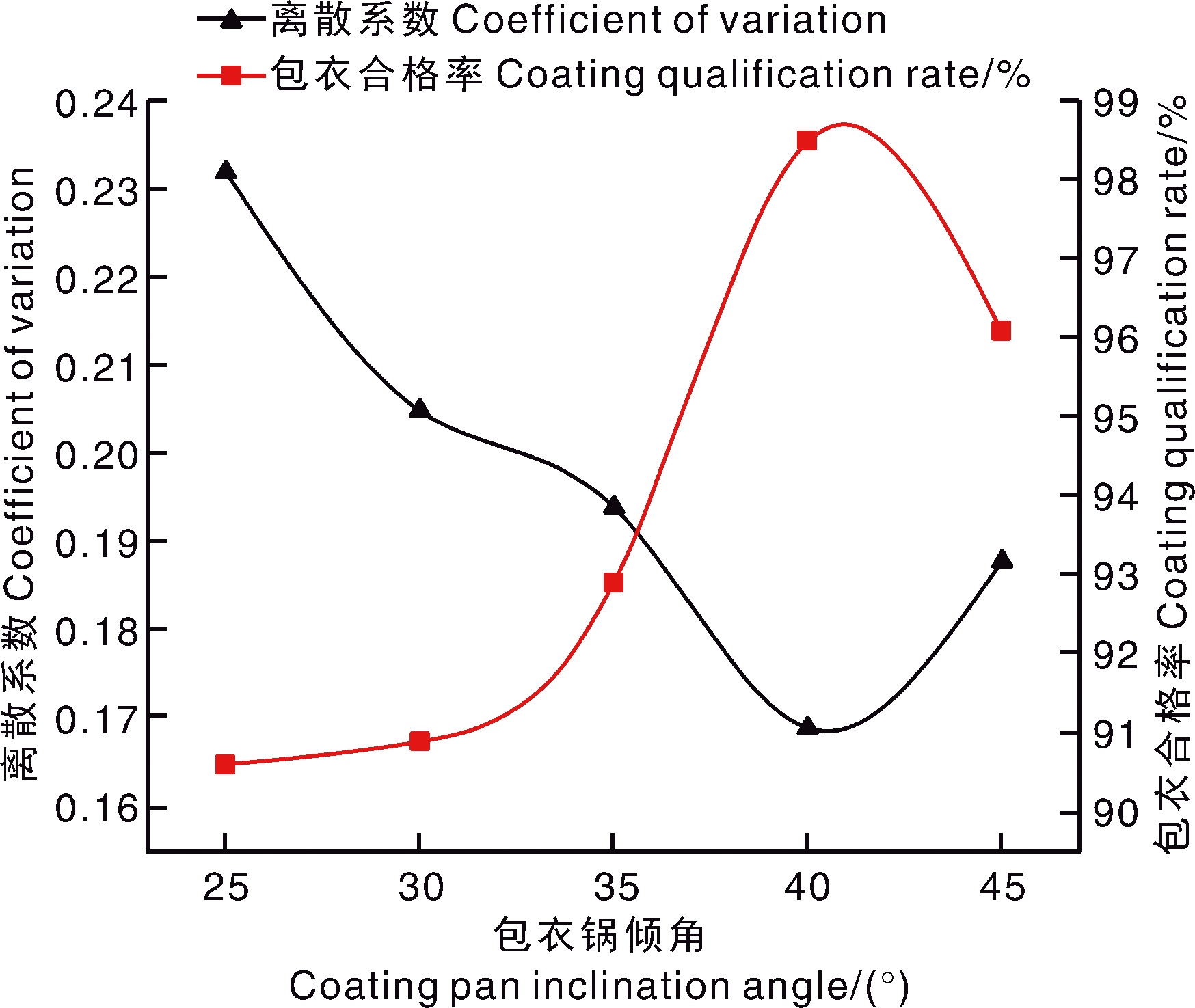

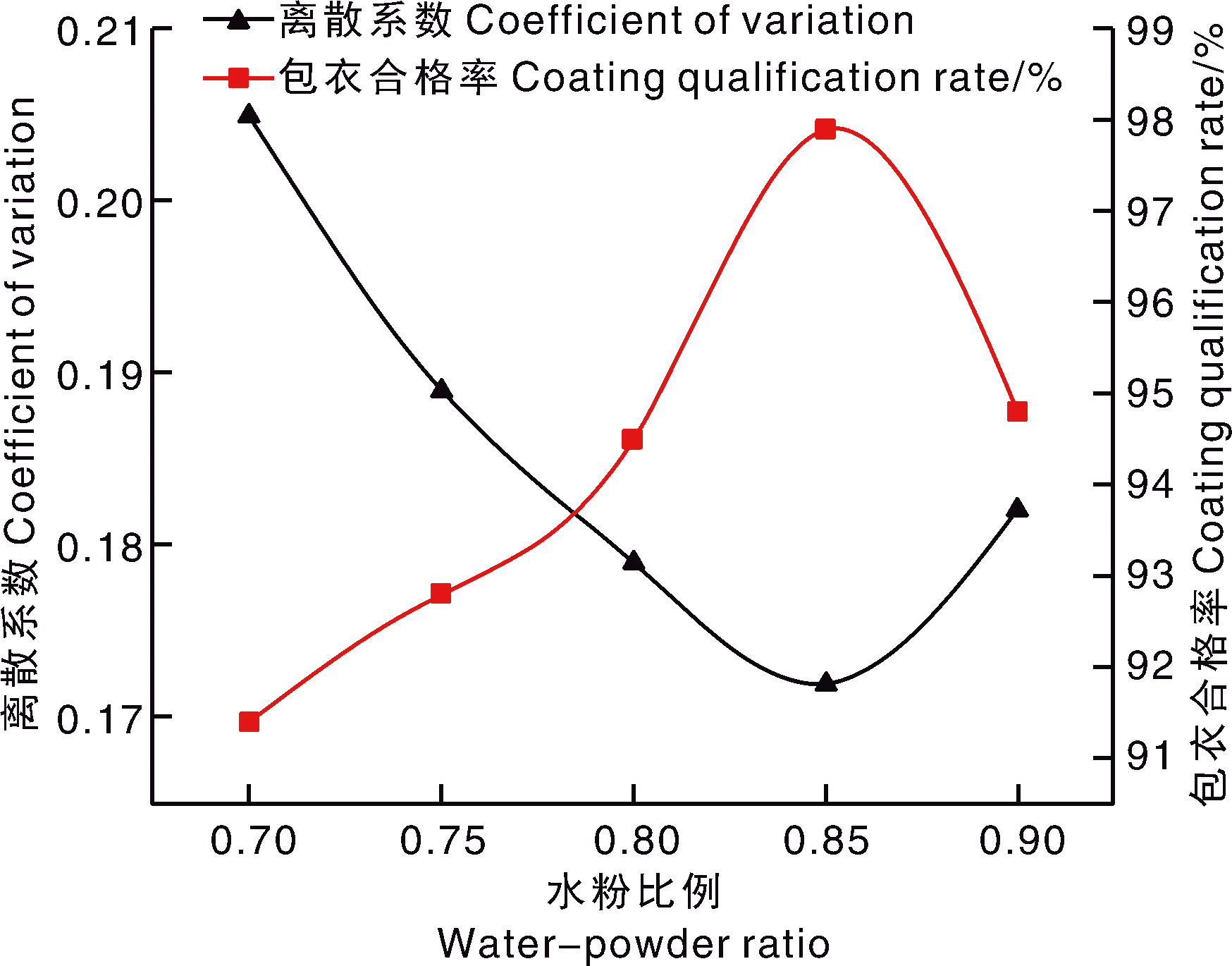

摘要: 为研究椭球形小籽粒党参种子丸粒化包衣工艺参数对包衣效果的影响,提升党参种子包衣合格率,借助颗粒接触理论,分析党参种子与包衣锅的接触过程,确定党参种子和包衣锅的基本参数。利用EDEM软件构建党参种子和包衣锅的离散元仿真模型,采用单因素试验分别研究包衣锅转速、包衣锅倾角和水粉比例对包衣合格率和离散系数的影响,利用正交试验建立以包衣合格率为响应参数的数学回归模型,通过方差分析得到影响包衣合格率的主次因素,通过响应曲面分析各因素交互作用对包衣合格率的影响。结果表明:影响党参种子包衣合格率的因素从高到低依次是包衣锅倾角>包衣锅转速>水粉比例。基于构建的回归方程得到如下最优参数:包衣锅转速30.7 r·min-1,包衣锅倾角40.7°,水粉比例0.85,此时,包衣合格率可达93%以上。

中图分类号:

引用本文

朱高烁, 高爱民, 李百成, 刘康康. 党参种子丸粒化包衣性能仿真与试验[J]. 浙江农业学报, 2025, 37(12): 2615-2624.

ZHU Gaoshuo, GAO Aimin, LI Baicheng, LIU Kangkang. Simulation and experiment on pelleting coating performance of Codonopsis pilosula seeds[J]. Acta Agriculturae Zhejiangensis, 2025, 37(12): 2615-2624.

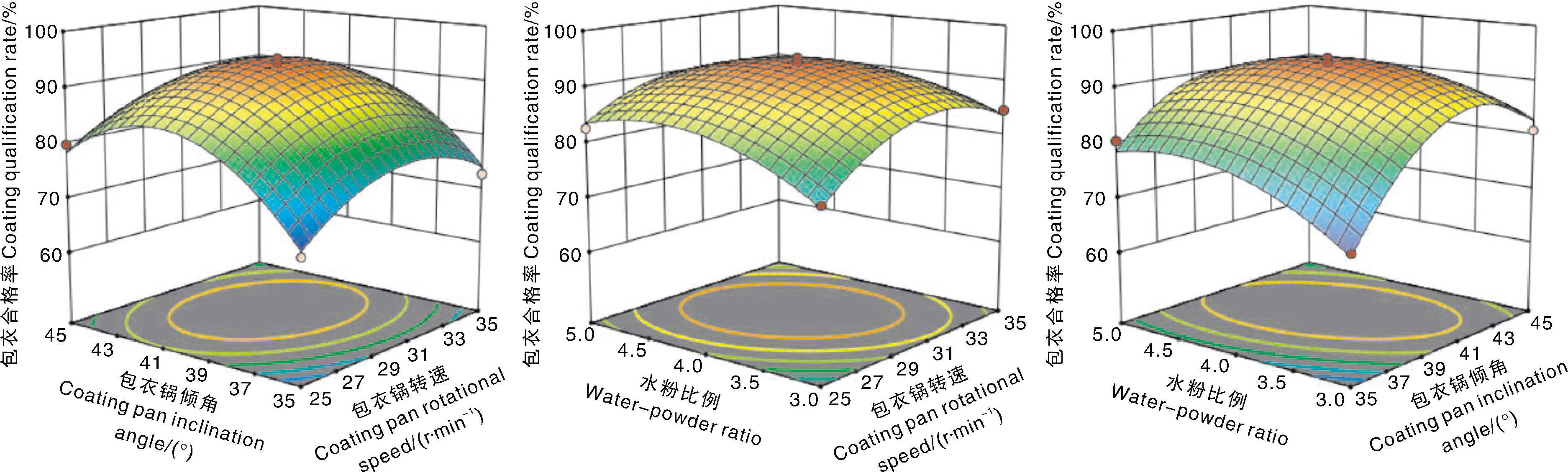

图1 种子丸粒化包衣机的结构示意图与实物图 1,药液瓶;2,药液控制阀;3,计量器;4,包衣锅;5,导管;6,控制系统;7,气压泵;8,喷头支架;9,雾化喷头;10,角度调节装置;11,工作平台;12,升降装置;13,支架。

Fig.1 Schematic diagram and physical diagram of the structure of seed pelleting and coating machine 1, Solution bottle; 2, Solution control valve; 3, Metering device; 4, Coating pot; 5, Conduit; 6, Control system; 7, Air pressure pump; 8, Spray nozzle bracket; 9, Atomizing spray nozzle; 10, Angle adjustment device; 11, Work platform; 12, Lifting device; 13, Support frame.

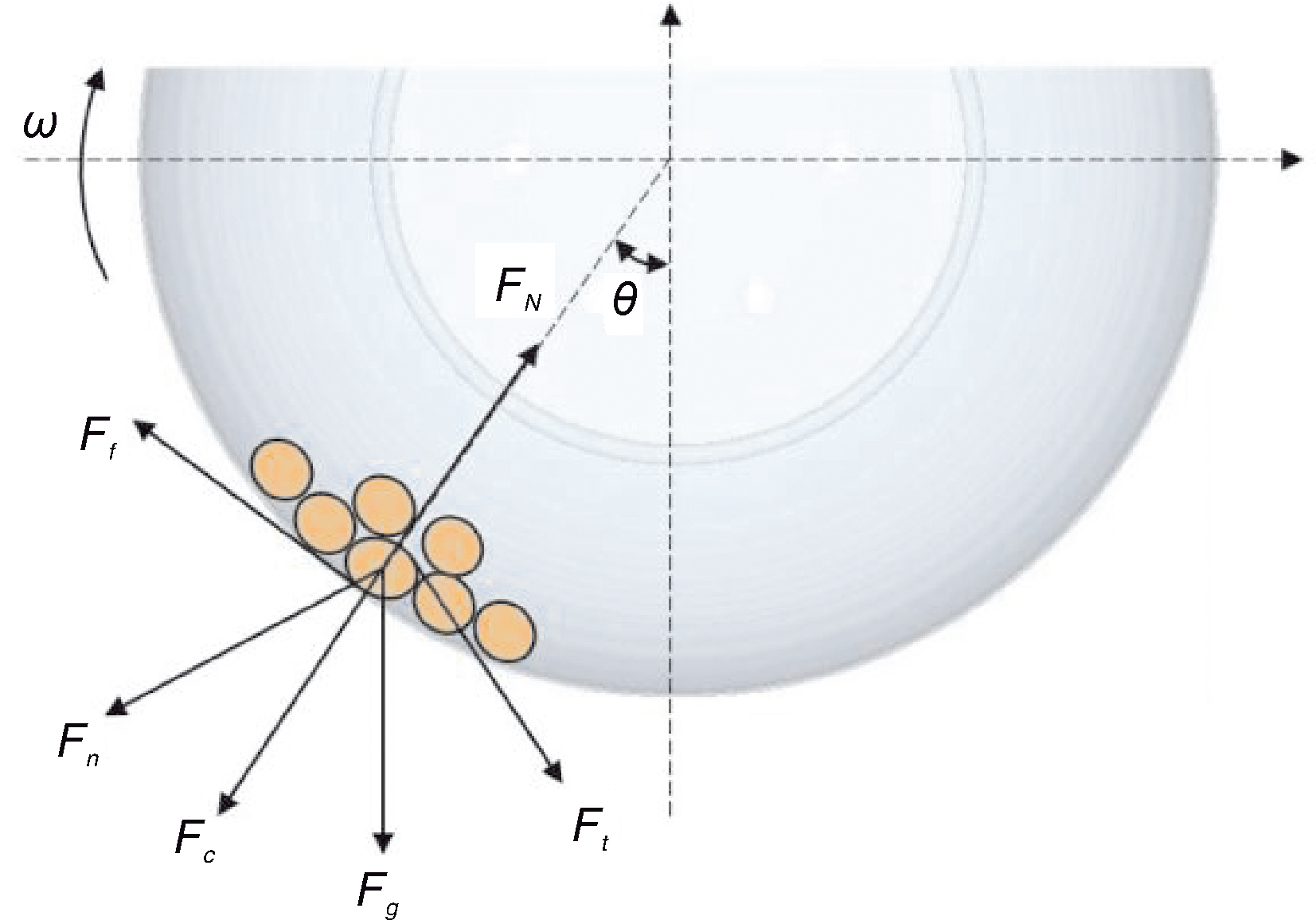

图3 种子受力分析图 Fn,种子间法向接触力;Ft,种子间切向接触力;Ff,种子与包衣锅间摩擦力;FN,支持力;Fc,离心力;Fg,重力;ω,包衣锅的角速度。

Fig.3 Force analysis diagram of seeds Fn is the normal contact force between seeds; Ft is the tangential contact force between seeds; Ff is the friction force between seeds and the coating pan; FN is the supporting force; Fc is the centrifugal force; Fg is the gravity; ω is the angular velocity of the coating pan.

| 指标 Indicator | 种子-种子 Seed-seed | 种子-粉料 Seed-powder | 粉料-粉料 Powder-powder | 种子-锅体 Seed-pot | 粉料-锅体 Powder-pot |

|---|---|---|---|---|---|

| 恢复系数Coefficient of restitution | 0.25 | 0.15 | 0.18 | 0.35 | 0.68 |

| 静摩擦系数Coefficient of static friction | 0.41 | 0.58 | 0.81 | 0.62 | 0.45 |

| 滚动摩擦系数Coefficient of rolling friction | 0.01 | 0.05 | 0.05 | 0.01 | 0.15 |

表1 仿真参数设置

Table 1 Setting values of simulation parameters

| 指标 Indicator | 种子-种子 Seed-seed | 种子-粉料 Seed-powder | 粉料-粉料 Powder-powder | 种子-锅体 Seed-pot | 粉料-锅体 Powder-pot |

|---|---|---|---|---|---|

| 恢复系数Coefficient of restitution | 0.25 | 0.15 | 0.18 | 0.35 | 0.68 |

| 静摩擦系数Coefficient of static friction | 0.41 | 0.58 | 0.81 | 0.62 | 0.45 |

| 滚动摩擦系数Coefficient of rolling friction | 0.01 | 0.05 | 0.05 | 0.01 | 0.15 |

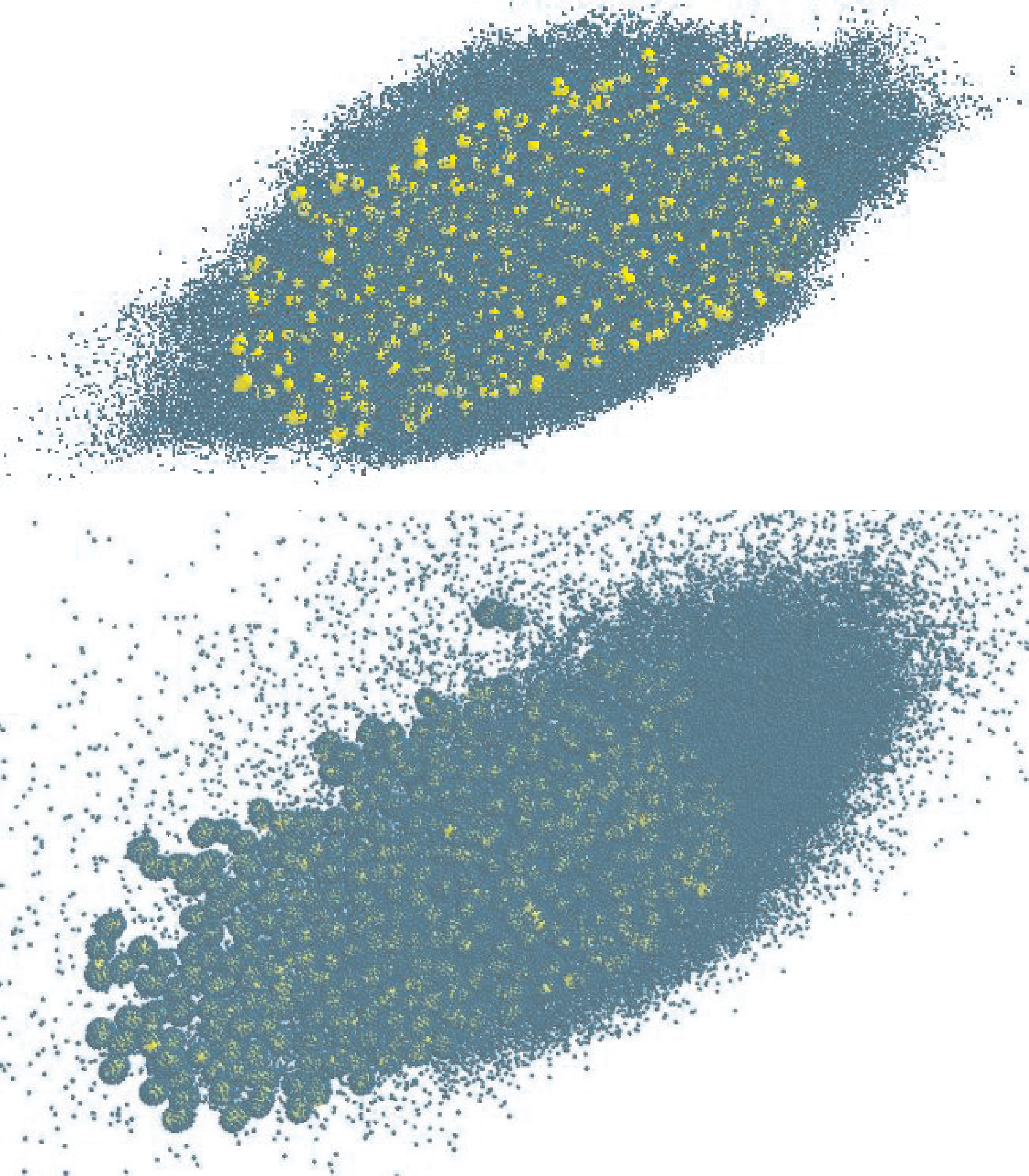

图6 包衣过程混合中期(上)和后期(下)的种子、粉粒混合效果示意图

Fig.6 Schematic diagram of seed and powder mixing effect in the middle stage (top) and late stage (bottom) of coating process

| 编码水平 Coding level | 各因素的设定值Setting values of factors | ||

|---|---|---|---|

| A/(r·min-1) | B/(°) | C | |

| -1 | 25 | 30 | 0.80 |

| 0 | 30 | 35 | 0.85 |

| 1 | 35 | 40 | 0.90 |

表2 不同编码水平各试验因素的设定值

Table 2 Setting values of factors under different coding levels

| 编码水平 Coding level | 各因素的设定值Setting values of factors | ||

|---|---|---|---|

| A/(r·min-1) | B/(°) | C | |

| -1 | 25 | 30 | 0.80 |

| 0 | 30 | 35 | 0.85 |

| 1 | 35 | 40 | 0.90 |

| 试验序号 Test No. | A/(r·min-1) | B/(°) | C | Y/% |

|---|---|---|---|---|

| 1 | 35 | 40 | 0.80 | 85.4 |

| 2 | 30 | 40 | 0.85 | 93.7 |

| 3 | 25 | 45 | 0.85 | 80.1 |

| 4 | 25 | 35 | 0.85 | 67.5 |

| 5 | 30 | 40 | 0.85 | 91.7 |

| 6 | 25 | 40 | 0.80 | 76.8 |

| 7 | 30 | 35 | 0.80 | 68.3 |

| 8 | 30 | 35 | 0.90 | 80.8 |

| 9 | 30 | 40 | 0.85 | 93.6 |

| 10 | 25 | 40 | 0.90 | 83.3 |

| 11 | 35 | 35 | 0.85 | 76.3 |

| 12 | 35 | 40 | 0.90 | 82.1 |

| 13 | 30 | 40 | 0.85 | 93.5 |

| 14 | 30 | 40 | 0.85 | 94.7 |

| 15 | 30 | 45 | 0.90 | 78.6 |

| 16 | 30 | 45 | 0.80 | 80.9 |

| 17 | 35 | 45 | 0.85 | 81.2 |

表3 正交试验方案与结果

Table 3 Scheme and results of orthogonal test

| 试验序号 Test No. | A/(r·min-1) | B/(°) | C | Y/% |

|---|---|---|---|---|

| 1 | 35 | 40 | 0.80 | 85.4 |

| 2 | 30 | 40 | 0.85 | 93.7 |

| 3 | 25 | 45 | 0.85 | 80.1 |

| 4 | 25 | 35 | 0.85 | 67.5 |

| 5 | 30 | 40 | 0.85 | 91.7 |

| 6 | 25 | 40 | 0.80 | 76.8 |

| 7 | 30 | 35 | 0.80 | 68.3 |

| 8 | 30 | 35 | 0.90 | 80.8 |

| 9 | 30 | 40 | 0.85 | 93.6 |

| 10 | 25 | 40 | 0.90 | 83.3 |

| 11 | 35 | 35 | 0.85 | 76.3 |

| 12 | 35 | 40 | 0.90 | 82.1 |

| 13 | 30 | 40 | 0.85 | 93.5 |

| 14 | 30 | 40 | 0.85 | 94.7 |

| 15 | 30 | 45 | 0.90 | 78.6 |

| 16 | 30 | 45 | 0.80 | 80.9 |

| 17 | 35 | 45 | 0.85 | 81.2 |

| [1] | 王红燕, 陈垣, 郭凤霞, 等. 党参属种质资源多样性及可药用种质创新研究进展[J]. 中草药, 2024, 55(3): 978-988. |

| WANG H Y, CHEN Y, GUO F X, et al. Research progress on diversity of Codonopsis genus resources and innovation of medicinal germplasm[J]. Chinese Traditional and Herbal Drugs, 2024, 55(3): 978-988. (in Chinese with English abstract) | |

| [2] | GAO S M, LIU J S, WANG M, et al. Traditional uses, phytochemistry, pharmacology and toxicology of Codonopsis: a review[J]. Journal of Ethnopharmacology, 2018, 219: 50-70. |

| [3] | 苏圆锦, 奚佳玉, 史奇, 等. 药食同源中药党参的研究进展[J]. 中草药, 2023, 54(8): 2607-2617. |

| SU Y J, XI J Y, SHI Q, et al. Research progress on Codonopsis radix as medicinal and edible traditional Chinese medicine[J]. Chinese Traditional and Herbal Drugs, 2023, 54(8): 2607-2617. (in Chinese with English abstract) | |

| [4] | 杨豆豆, 陈垣, 郭凤霞, 等. 党参地上部分研究和应用的进展[J]. 中草药, 2021, 52(13): 4055-4063. |

| YANG D D, CHEN Y, GUO F X, et al. Study and application of above-ground parts of Codonopsis pilosula[J]. Chinese Traditional and Herbal Drugs, 2021, 52(13): 4055-4063. (in Chinese with English abstract) | |

| [5] | 李冉, 张文广, 成春亚, 等. 中药材种子种苗繁育关键技术研究进展[J]. 中国现代中药, 2022, 24(11): 2241-2248. |

| LI R, ZHANG W G, CHENG C Y, et al. Key breeding techniques of seeds and seedlings of Chinese medicinal materials[J]. Modern Chinese Medicine, 2022, 24(11): 2241-2248. (in Chinese with English abstract) | |

| [6] | 后文刚. 浅析甘肃卓尼县党参机械化播种技术[J]. 农业机械, 2023(10): 91-93. |

| HOU W G. Analysis on mechanized seeding technology of Codonopsis pilosula in Zhuoni, Gansu Province[J]. Farm Machinery, 2023(10): 91-93. (in Chinese with English abstract) | |

| [7] | MA X J, LIU M, HOU Z F, et al. Calibration and experimental studies on the mixing parameters of red clover seeds and coated powders[J]. Processes, 2022, 10(11): 2280. |

| [8] | 李向东, 蒋靖怡, 王娟娟, 等. 中药材工厂化育苗现状及发展趋势[J]. 中国现代中药, 2021, 23(11): 1857-1863. |

| LI X D, JIANG J Y, WANG J J, et al. Status quo and development trend of industrial seedling raising of Chinese medicinal materials[J]. Modern Chinese Medicine, 2021, 23(11): 1857-1863. (in Chinese with English abstract) | |

| [9] | PASHA M, HARE C, GHADIRI M, et al. Inter-particle coating variability in a rotary batch seed coater[J]. Chemical Engineering Research and Design, 2017, 120: 92-101. |

| [10] | 王海鸥, 胡志超, 田立佳, 等. 种子丸化技术及其研究与应用概况[J]. 现代农业装备, 2006, 27(10): 48-50. |

| WANG H O, HU Z C, TIAN L J, et al. Seed pelleting technique and status of its researching and application[J]. Modern Agricultural Equipments, 2006, 27(10): 48-50. (in Chinese with English abstract) | |

| [11] | ROCHA I, MA Y, SOUZA-ALONSO P, et al. Seed coating: a tool for delivering beneficial microbes to agricultural crops[J]. Frontiers in Plant Science, 2019, 10: 1357. |

| [12] | LIU M, HOU Z F, MA X J, et al. Determination and testing of pelletized coated particles[J]. INMATEH: Agricultural Engineering, 2022: 247-256. |

| [13] | KORISHETTAR P, VASUDEVAN S N, SHAKUNTALA N M, et al. Seed polymer coating with Zn and Fe nanoparticles: an innovative seed quality enhancement technique in pigeonpea[J]. Journal of Applied and Natural Science, 2016, 8(1): 445-450. |

| [14] | 刘敏, 侯占峰, 戴念祖, 等. 紫花苜蓿种子丸化包衣工作参数优化设计[J]. 农机化研究, 2023, 45(7): 136-142. |

| LIU M, HOU Z F, DAI N Z, et al. Optimization of technological parameters for pelletizing and coating of Medicago sativa seeds based on EDEM[J]. Journal of Agricultural Mechanization Research, 2023, 45(7): 136-142. (in Chinese with English abstract) | |

| [15] | 邵志威, 陈智, 侯占峰, 等. BYW-400型冰草种子振动丸粒化包衣机种子丸化运动特性[J]. 农业工程学报, 2018, 34(3): 57-64. |

| SHAO Z W, CHEN Z, HOU Z F, et al. Analysis of pelleting movement characteristics of BYW-400 type vibrating seed coating machine for wheatgrass[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(3): 57-64. (in Chinese with English abstract) | |

| [16] | 王建楠, 谢焕雄, 胡志超, 等. 甩盘滚筒式花生种子机械化包衣工艺参数优化[J]. 农业工程学报, 2017, 33(7): 43-50. |

| WANG J N, XIE H X, HU Z C, et al. Parameter optimization on mechanical coating processing of rotary table-roller coating machine for peanut seeds[J]. Transactions of the Chinese Society of Agricultural Engineering, 2017, 33(7): 43-50. (in Chinese with English abstract) | |

| [17] | 李建军, 史春梅, 孟庆祥, 等. 5 BY型种子包衣机最佳工艺参数研究[J]. 种子, 2019, 38(6): 13-18. |

| LI J J, SHI C M, MENG Q X, et al. Study on the optimum technological parameters of 5 BY seed-coating machine[J]. Seed, 2019, 38(6): 13-18. (in Chinese with English abstract) | |

| [18] | 马学杰, 刘敏, 侯占峰, 等. 小粒牧草种子丸粒化包衣数值模拟与试验[J]. 农业工程学报, 2023, 39(2): 43-52. |

| MA X J, LIU M, HOU Z F, et al. Numerical simulation and experiment on pelleting coating of small forage seeds[J]. Transactions of the Chinese Society of Agricultural Engineering, 2023, 39(2): 43-52. (in Chinese with English abstract) | |

| [19] | 侯占峰, 陈利杰, 陈智, 等. 牧草种子丸粒化包衣运动规律与参数优选研究[J]. 农机化研究, 2021, 43(11): 184-191. |

| HOU Z F, CHEN L J, CHEN Z, et al. Study on motion law and optimum parameters of pelleted coating of forage seeds based on discrete element method[J]. Journal of Agricultural Mechanization Research, 2021, 43(11): 184-191. (in Chinese with English abstract) | |

| [20] | 孙正. 番茄种子包衣丸化关键技术研究与装备开发[D]. 北京: 中国农业机械化科学研究院, 2016. |

| SUN Z. Key technology research and equipment development of tomato seeds coating granulation[D]. Beijing: Chinese Academy of Agricultural Mechanization Sciences, 2016. (in Chinese with English abstract) | |

| [21] | MADLMEIR S, FORGBER T, TROGRLIC M, et al. Modeling the coating layer thickness in a pharmaceutical coating process[J]. European Journal of Pharmaceutical Sciences, 2021, 161: 105770. |

| [22] | TANG T Q, HE Y R, REN A X, et al. Experimental study and DEM numerical simulation of dry/wet particle flow behaviors in a spouted bed[J]. Industrial & Engineering Chemistry Research, 2019, 58(33): 15353-15367. |

| [23] | ZHENG X P, HUANG J Q, LI Y L, et al. Numerical simulation method of seed pelletizing: increasing seed size by powder adhesion[J]. Powder Technology, 2024, 444: 119991. |

| [24] | PASHA M, HARE C, GHADIRI M, et al. Effect of particle shape on flow in discrete element method simulation of a rotary batch seed coater[J]. Powder Technology, 2016, 296: 29-36. |

| [25] | 董晨希, 武甜, 吕兴坤. 基于EDEM对振动搅拌的仿真分析[J]. 机械研究与应用, 2017, 30(1): 38-41. |

| DONG C X, WU T, LV X K. Simulation analysis of vibratory mixing based on the EDEM[J]. Mechanical Research & Application, 2017, 30(1): 38-41. (in Chinese with English abstract) | |

| [26] | 戴念祖. 冰草种子丸粒化振动包衣机的设计与试验[D]. 呼和浩特: 内蒙古农业大学, 2021. |

| DAI N Z. Design and experiment of pelleting vibratory coating machine for agropyson seed[D]. Hohhot: Inner Mongolia Agricultural University, 2021. (in Chinese with English abstract) |

| No related articles found! |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||