浙江农业学报 ›› 2025, Vol. 37 ›› Issue (12): 2563-2573.DOI: 10.3969/j.issn.1004-1524.20240710

枯草芽孢杆菌沙漠亚种kc-16培养条件的优化

杨学宇1,2( ), 牛丽1, 谭琳3, 邓玉莲1, 包强4,*(

), 牛丽1, 谭琳3, 邓玉莲1, 包强4,*( ), 胡秋龙1,*(

), 胡秋龙1,*( )

)

- 1.湖南农业大学 园艺学院,湖南 长沙 410128

2.湖南省烟草公司郴州市公司,湖南 郴州 423000

3.湖南农业大学 植物保护学院,湖南 长沙 410128

4.湖南省农业科学院 茶叶研究所,湖南 长沙 410125

-

收稿日期:2024-08-06出版日期:2025-12-25发布日期:2026-01-09 -

作者简介:杨学宇(1998—),男,山西大同人,硕士,从事茶树病虫害生物防治研究。E-mail:1743501922@qq.com -

通讯作者:*包强,E-mail:baoqiang0703@126.com;胡秋龙,E-mail:huqiulongnet@126.com -

基金资助:湖南省重点研发计划(2022NK2051);湖南省重点研发计划(2023NK2013);湖南省科技创新重大项目(2021NK1020);国家重点研发计划项目(2022YFD1600800)

Optimization of the culture conditions of Bacillus subtilis subsp. inaquosorum kc-16

YANG Xueyu1,2( ), NIU Li1, TAN Lin3, DENG Yulian1, BAO Qiang4,*(

), NIU Li1, TAN Lin3, DENG Yulian1, BAO Qiang4,*( ), HU Qiulong1,*(

), HU Qiulong1,*( )

)

- 1. College of Horticulture, Hunan Agricultural University, Changsha 410128, China

2. Chenzhou Branch of Hunan Tobacco Company, Chenzhou 423000, Hunan, China

3. College of Plant Protection, Hunan Agricultural University, Changsha 410128, China

4. Tea Research Institute, Hunan Academy of Agricultural Sciences, Changsha 410125, China

-

Received:2024-08-06Online:2025-12-25Published:2026-01-09

摘要: 为优化枯草芽孢杆菌沙漠亚种(Bacillus subtilis subsp. inaquosorum)菌株kc-16的培养条件,提高其生物量与抑菌活性,本研究通过单因素试验初步筛选最适碳源、氮源、无机盐种类及其对应的质量分数范围,进一步采用Plackett-Burman试验确定影响菌液D600(600 nm处的吸光度)的关键因子。在此基础上,以菌液D600为响应值,通过Box-Behnken设计构建显著因子与生物量的非线性方程,预测并验证菌株kc-16的最佳培养条件。结果表明,最优培养基组分(质量分数)为0.5%乳糖、4.0%蛋白胨、0.1%硫酸镁、0.6%氯化钠、0.2%碳酸钙;培养条件为转速200 r·min-1、初始pH值7.7、温度30 ℃、接种量0.6%(体积比)。在此条件下,模型预测的发酵液D600为0.112,实测值为0.307,二者吻合较好。平板计数法结果显示,优化后的活菌数为6.7×109 CFU·mL-1,是优化前(4.0×108 CFU·mL-1)的16.75倍。本研究通过单因素试验结合响应面法实现了菌株kc-16培养条件的优化,为该菌株的规模化生产与应用提供支持。

中图分类号:

引用本文

杨学宇, 牛丽, 谭琳, 邓玉莲, 包强, 胡秋龙. 枯草芽孢杆菌沙漠亚种kc-16培养条件的优化[J]. 浙江农业学报, 2025, 37(12): 2563-2573.

YANG Xueyu, NIU Li, TAN Lin, DENG Yulian, BAO Qiang, HU Qiulong. Optimization of the culture conditions of Bacillus subtilis subsp. inaquosorum kc-16[J]. Acta Agriculturae Zhejiangensis, 2025, 37(12): 2563-2573.

| 水平Level | A/% | B/% | C/% | D/% | E/% | F | G/(r·min-1) | H/℃ | I/% |

|---|---|---|---|---|---|---|---|---|---|

| 高水平 | 1.0 | 5 | 0.2 | 0.8 | 0.4 | 8 | 220 | 32 | 1.0 |

| 低水平 | 0.5 | 3 | 0.1 | 0.4 | 0.1 | 7 | 180 | 28 | 0.5 |

表1 Plackett-Burman试验因素与水平表

Table 1 Factors and levels for the Plackett-Burman design

| 水平Level | A/% | B/% | C/% | D/% | E/% | F | G/(r·min-1) | H/℃ | I/% |

|---|---|---|---|---|---|---|---|---|---|

| 高水平 | 1.0 | 5 | 0.2 | 0.8 | 0.4 | 8 | 220 | 32 | 1.0 |

| 低水平 | 0.5 | 3 | 0.1 | 0.4 | 0.1 | 7 | 180 | 28 | 0.5 |

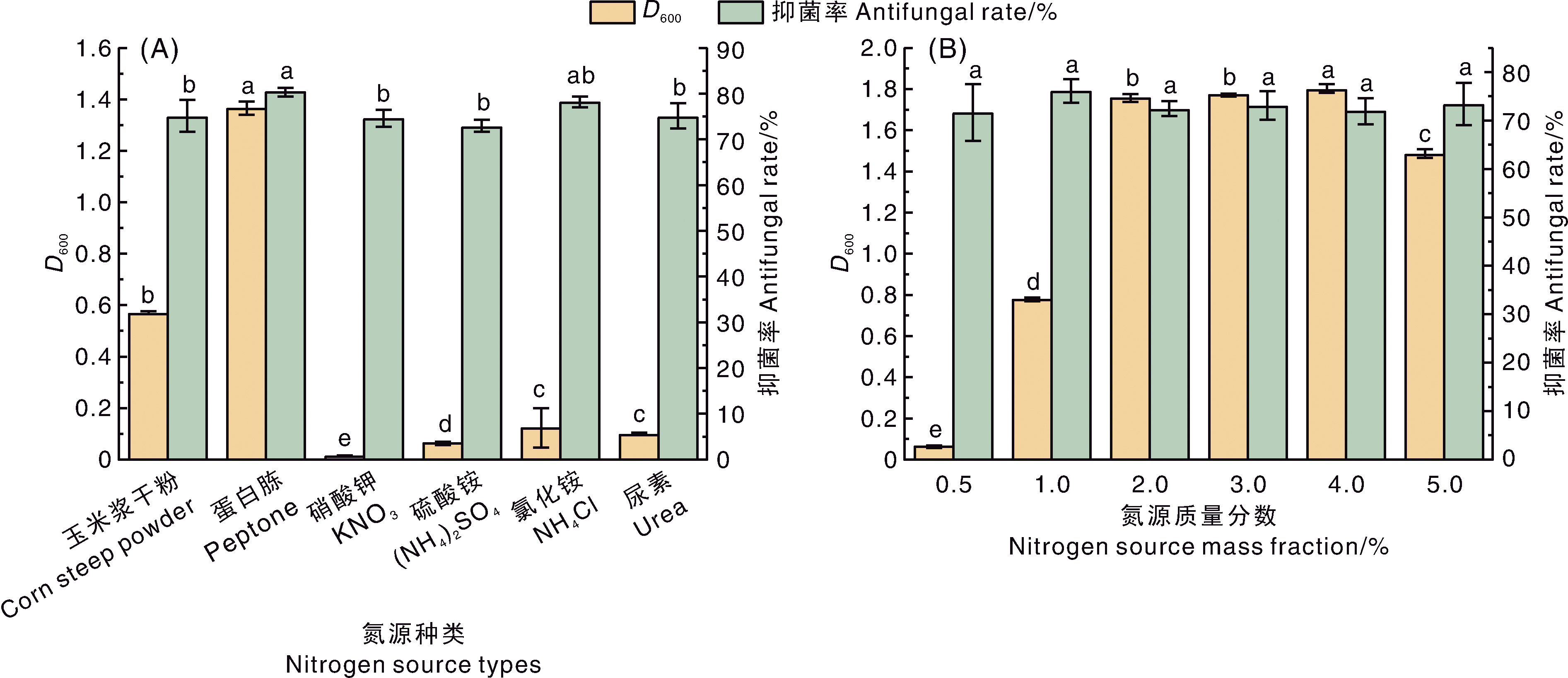

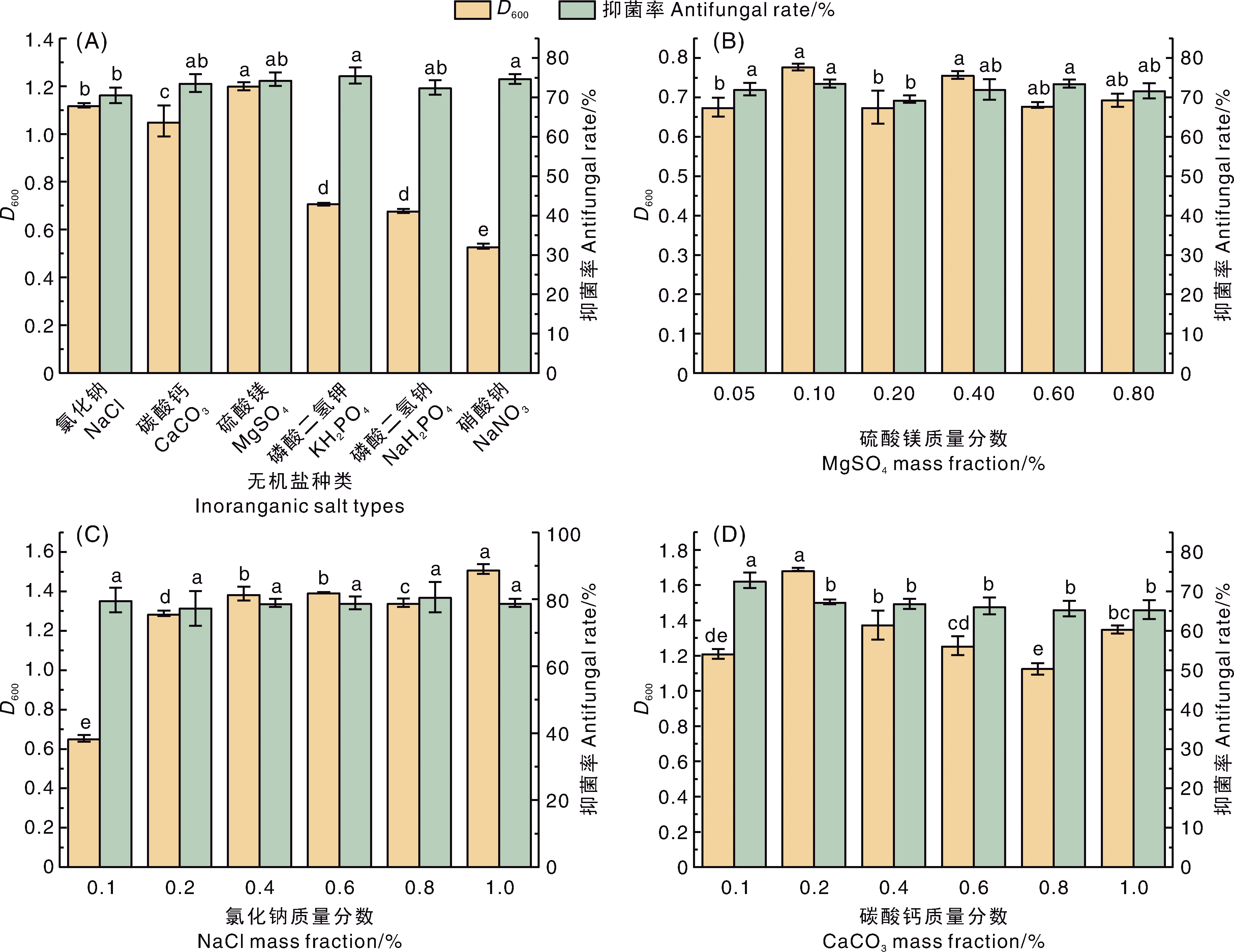

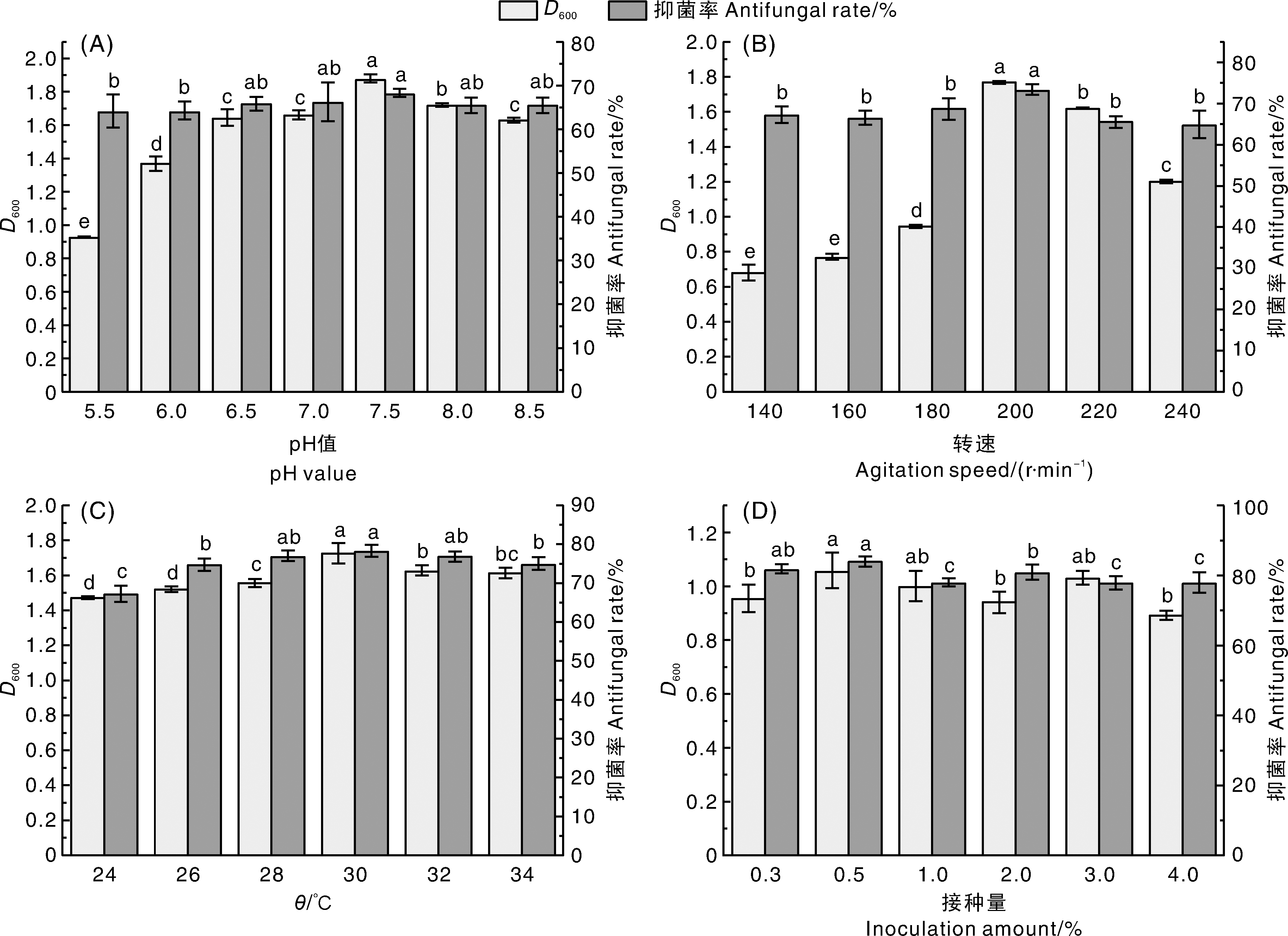

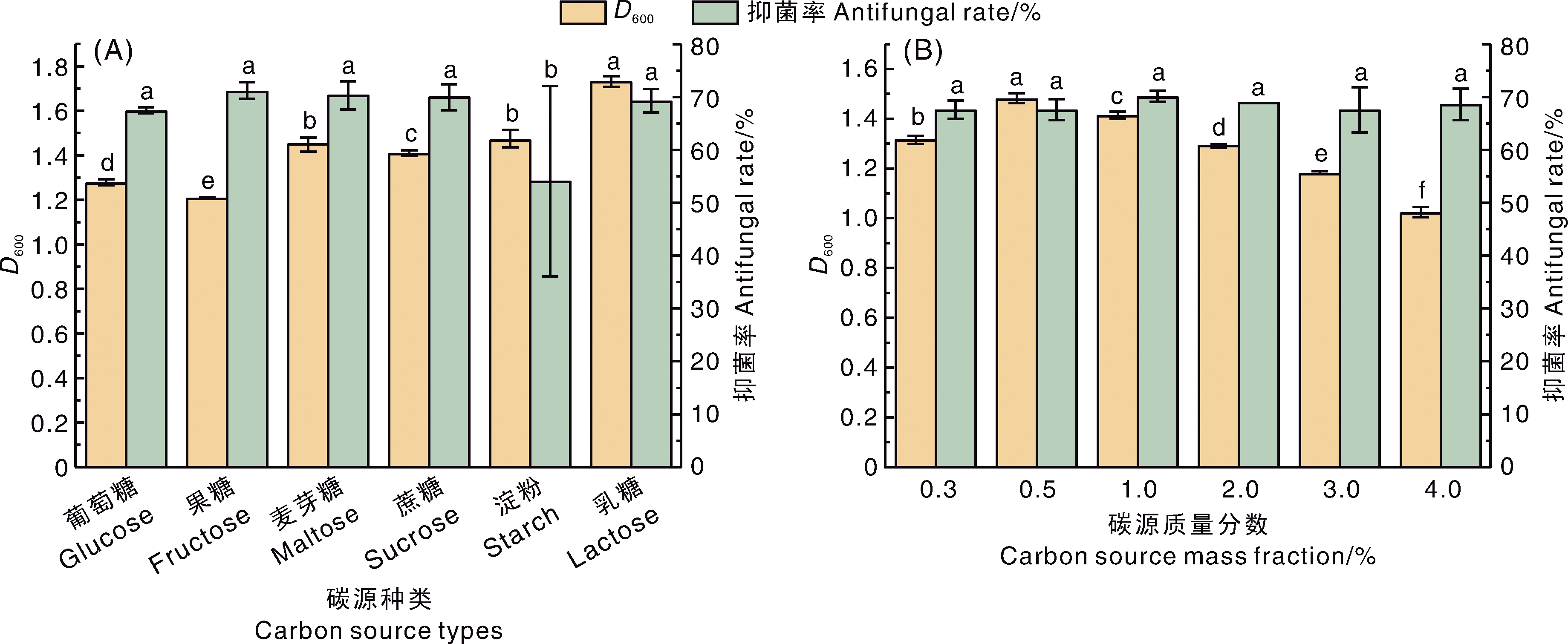

图1 碳源种类与质量分数筛选 柱上无相同小写字母表示不同处理间的相应指标差异显著(p<0.05)。下同。

Fig.1 Selection of carbon source types and mass fractions The absence of the same lowercase letters on the column indicates a significant (p<0.05) difference in the corresponding indicators among different treatments. The same as below.

| 组别Group | A/% | B/% | C/% | D/% | E/% | F | G/(r·min-1) | H/℃ | I/% | D600 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.0 | 5 | 0.1 | 0.8 | 0.4 | 8 | 180 | 28 | 0.5 | 1.68 |

| 2 | 0.5 | 5 | 0.2 | 0.4 | 0.4 | 8 | 220 | 28 | 0.5 | 0.32 |

| 3 | 1.0 | 3 | 0.2 | 0.8 | 0.1 | 8 | 220 | 32 | 0.5 | 0.10 |

| 4 | 0.5 | 5 | 0.1 | 0.8 | 0.4 | 7 | 220 | 32 | 1.0 | 0.16 |

| 5 | 0.5 | 3 | 0.2 | 0.4 | 0.4 | 8 | 180 | 32 | 1.0 | 0.80 |

| 6 | 0.5 | 3 | 0.1 | 0.8 | 0.1 | 8 | 220 | 28 | 1.0 | 0.18 |

| 7 | 1.0 | 3 | 0.1 | 0.4 | 0.4 | 7 | 220 | 32 | 0.5 | 1.90 |

| 8 | 1.0 | 5 | 0.1 | 0.4 | 0.1 | 8 | 180 | 32 | 1.0 | 0.33 |

| 9 | 1.0 | 5 | 0.2 | 0.4 | 0.1 | 7 | 220 | 28 | 1.0 | 1.98 |

| 10 | 0.5 | 5 | 0.2 | 0.8 | 0.1 | 7 | 180 | 32 | 0.5 | 1.97 |

| 11 | 1.0 | 3 | 0.2 | 0.8 | 0.4 | 7 | 180 | 28 | 1.0 | 1.89 |

| 12 | 0.5 | 3 | 0.1 | 0.4 | 0.1 | 7 | 180 | 28 | 0.5 | 1.77 |

表2 Plackett-Burman (PB)试验设计与试验结果

Table 2 Plackett-Burman (PB) experiment design and results

| 组别Group | A/% | B/% | C/% | D/% | E/% | F | G/(r·min-1) | H/℃ | I/% | D600 |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 1.0 | 5 | 0.1 | 0.8 | 0.4 | 8 | 180 | 28 | 0.5 | 1.68 |

| 2 | 0.5 | 5 | 0.2 | 0.4 | 0.4 | 8 | 220 | 28 | 0.5 | 0.32 |

| 3 | 1.0 | 3 | 0.2 | 0.8 | 0.1 | 8 | 220 | 32 | 0.5 | 0.10 |

| 4 | 0.5 | 5 | 0.1 | 0.8 | 0.4 | 7 | 220 | 32 | 1.0 | 0.16 |

| 5 | 0.5 | 3 | 0.2 | 0.4 | 0.4 | 8 | 180 | 32 | 1.0 | 0.80 |

| 6 | 0.5 | 3 | 0.1 | 0.8 | 0.1 | 8 | 220 | 28 | 1.0 | 0.18 |

| 7 | 1.0 | 3 | 0.1 | 0.4 | 0.4 | 7 | 220 | 32 | 0.5 | 1.90 |

| 8 | 1.0 | 5 | 0.1 | 0.4 | 0.1 | 8 | 180 | 32 | 1.0 | 0.33 |

| 9 | 1.0 | 5 | 0.2 | 0.4 | 0.1 | 7 | 220 | 28 | 1.0 | 1.98 |

| 10 | 0.5 | 5 | 0.2 | 0.8 | 0.1 | 7 | 180 | 32 | 0.5 | 1.97 |

| 11 | 1.0 | 3 | 0.2 | 0.8 | 0.4 | 7 | 180 | 28 | 1.0 | 1.89 |

| 12 | 0.5 | 3 | 0.1 | 0.4 | 0.1 | 7 | 180 | 28 | 0.5 | 1.77 |

| 方差来源 Soruce | 平方和 Sum of squares | 自由度 Degree of freedom | 均方差 Mean square | F值 F value | p | 标准化效应 Standardization effect | 系数 Coefficient | 贡献率 Contribution rate/% | 重要性排序 Importance rank |

|---|---|---|---|---|---|---|---|---|---|

| A | 0.145 200 | 1 | 0.145 200 | 256.235 300 | 0.003 880 | -0.220 000 | -0.110 000 | 14.508 390 | 4 |

| B | 0.003 333 | 1 | 0.003 333 | 5.882 353 | 0.136 132 | -0.033 330 | -0.016 670 | 0.333 067 | 8 |

| C | 0.090 133 | 1 | 0.090 133 | 159.058 800 | 0.006 228 | 0.173 333 | 0.086 667 | 9.006 128 | 6 |

| D | 0.104 533 | 1 | 0.104 533 | 184.470 600 | 0.005 377 | -0.186 670 | -0.093 330 | 10.444 980 | 5 |

| E | 0.014 700 | 1 | 0.014 700 | 25.941 180 | 0.036 454 | 0.070 000 | 0.035 000 | 1.468 825 | 7 |

| F | 0.252 300 | 1 | 0.252 300 | 445.235 300 | 0.002 238 | 0.290 000 | 0.145 000 | 25.209 830 | 1 |

| G | 0.003 333 | 1 | 0.003 333 | 5.882 353 | 0.136 132 | 0.033 333 | 0.016 667 | 0.333 067 | 9 |

| H | 0.172 800 | 1 | 0.172 800 | 304.941 200 | 0.003 263 | 0.240 000 | 0.120 000 | 17.266 190 | 3 |

| I | 0.213 333 | 1 | 0.213 333 | 376.470 600 | 0.002 646 | 0.266 667 | 0.133 333 | 21.316 280 | 2 |

| 残差Residual | 0.001 133 | 2 | 0.000 567 | — | — | — | — | — | — |

| 总离差平方和 | 1.000 798 | 11 | — | — | — | — | — | — | — |

| Cor Total | |||||||||

| 模型Model | 0.999 665 | 9 | 0.111 074 | 196.013 100 | 0.005 086 | Significant | — | — | — |

表3 PB试验各因素方差分析

Table 3 Analysis of variance (ANOVA) for each factor in the PB experiment

| 方差来源 Soruce | 平方和 Sum of squares | 自由度 Degree of freedom | 均方差 Mean square | F值 F value | p | 标准化效应 Standardization effect | 系数 Coefficient | 贡献率 Contribution rate/% | 重要性排序 Importance rank |

|---|---|---|---|---|---|---|---|---|---|

| A | 0.145 200 | 1 | 0.145 200 | 256.235 300 | 0.003 880 | -0.220 000 | -0.110 000 | 14.508 390 | 4 |

| B | 0.003 333 | 1 | 0.003 333 | 5.882 353 | 0.136 132 | -0.033 330 | -0.016 670 | 0.333 067 | 8 |

| C | 0.090 133 | 1 | 0.090 133 | 159.058 800 | 0.006 228 | 0.173 333 | 0.086 667 | 9.006 128 | 6 |

| D | 0.104 533 | 1 | 0.104 533 | 184.470 600 | 0.005 377 | -0.186 670 | -0.093 330 | 10.444 980 | 5 |

| E | 0.014 700 | 1 | 0.014 700 | 25.941 180 | 0.036 454 | 0.070 000 | 0.035 000 | 1.468 825 | 7 |

| F | 0.252 300 | 1 | 0.252 300 | 445.235 300 | 0.002 238 | 0.290 000 | 0.145 000 | 25.209 830 | 1 |

| G | 0.003 333 | 1 | 0.003 333 | 5.882 353 | 0.136 132 | 0.033 333 | 0.016 667 | 0.333 067 | 9 |

| H | 0.172 800 | 1 | 0.172 800 | 304.941 200 | 0.003 263 | 0.240 000 | 0.120 000 | 17.266 190 | 3 |

| I | 0.213 333 | 1 | 0.213 333 | 376.470 600 | 0.002 646 | 0.266 667 | 0.133 333 | 21.316 280 | 2 |

| 残差Residual | 0.001 133 | 2 | 0.000 567 | — | — | — | — | — | — |

| 总离差平方和 | 1.000 798 | 11 | — | — | — | — | — | — | — |

| Cor Total | |||||||||

| 模型Model | 0.999 665 | 9 | 0.111 074 | 196.013 100 | 0.005 086 | Significant | — | — | — |

| 组别Group | F | I/% | H/℃ | D600 |

|---|---|---|---|---|

| 1 | 7.0 | 0.10 | 30 | 1.441 |

| 2 | 8.0 | 0.10 | 30 | 1.868 |

| 3 | 7.0 | 1.00 | 30 | 1.913 |

| 4 | 8.0 | 1.00 | 30 | 1.916 |

| 5 | 7.0 | 0.55 | 28 | 1.929 |

| 6 | 8.0 | 0.55 | 28 | 1.994 |

| 7 | 7.0 | 0.55 | 32 | 1.929 |

| 8 | 8.0 | 0.55 | 32 | 1.994 |

| 9 | 7.5 | 0.10 | 28 | 1.741 |

| 10 | 7.5 | 1.00 | 28 | 1.864 |

| 11 | 7.5 | 0.10 | 32 | 1.761 |

| 12 | 7.5 | 1.00 | 32 | 1.864 |

| 13 | 7.5 | 0.55 | 30 | 0.200 |

| 14 | 7.5 | 0.55 | 30 | 0.005 |

| 15 | 7.5 | 0.55 | 30 | 0.095 |

| 16 | 7.5 | 0.55 | 30 | 0.136 |

| 17 | 7.5 | 0.55 | 30 | 0.027 |

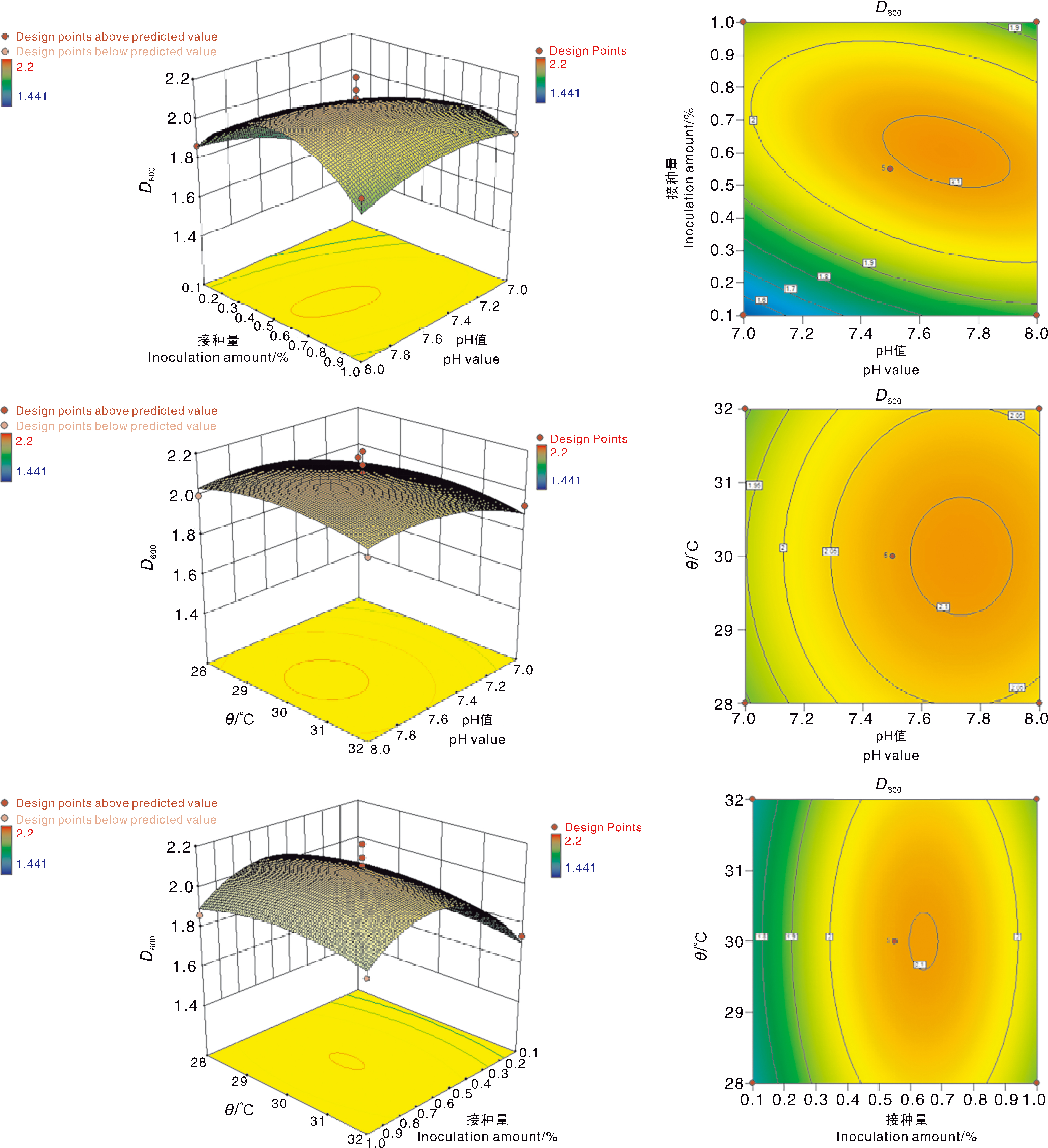

表4 Box-Behnken Design试验与结果

Table 4 Box-Behnken Design experiment and results

| 组别Group | F | I/% | H/℃ | D600 |

|---|---|---|---|---|

| 1 | 7.0 | 0.10 | 30 | 1.441 |

| 2 | 8.0 | 0.10 | 30 | 1.868 |

| 3 | 7.0 | 1.00 | 30 | 1.913 |

| 4 | 8.0 | 1.00 | 30 | 1.916 |

| 5 | 7.0 | 0.55 | 28 | 1.929 |

| 6 | 8.0 | 0.55 | 28 | 1.994 |

| 7 | 7.0 | 0.55 | 32 | 1.929 |

| 8 | 8.0 | 0.55 | 32 | 1.994 |

| 9 | 7.5 | 0.10 | 28 | 1.741 |

| 10 | 7.5 | 1.00 | 28 | 1.864 |

| 11 | 7.5 | 0.10 | 32 | 1.761 |

| 12 | 7.5 | 1.00 | 32 | 1.864 |

| 13 | 7.5 | 0.55 | 30 | 0.200 |

| 14 | 7.5 | 0.55 | 30 | 0.005 |

| 15 | 7.5 | 0.55 | 30 | 0.095 |

| 16 | 7.5 | 0.55 | 30 | 0.136 |

| 17 | 7.5 | 0.55 | 30 | 0.027 |

| 方差来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方差 Mean square | F值 F value | p |

|---|---|---|---|---|---|

| 模型Model | 0.430 | 9 | 0.048 | 7.100 | 0.008 5 |

| F | 0.039 | 1 | 0.039 | 5.780 | 0.047 2 |

| I | 0.070 | 1 | 0.070 | 10.250 | 0.015 0 |

| H | 5.000×10-5 | 1 | 5.000×10-5 | 7.368×10-3 | 0.934 0 |

| FI | 0.045 | 1 | 0.045 | 6.620 | 0.036 8 |

| FH | 5.551×10-17 | 1 | 5.551×10-17 | 8.180×10-15 | 1.000 0 |

| IH | 1.000×10-4 | 1 | 1.000×10-4 | 0.015 | 0.906 8 |

| F2 | 0.025 | 1 | 0.025 | 0.680 | 0.096 4 |

| I2 | 0.220 | 1 | 0.220 | 0.120 | 0.000 7 |

| H2 | 0.012 | 1 | 0.012 | 1.810 | 0.220 2 |

| 残差Residual | 0.048 | 7 | 6.787×10-3 | — | — |

| 失拟项Lack of fit | 0.022 | 3 | 7.368×10-3 | 1.160 | 0.428 0 |

| 纯误差Pure error | 0.025 | 4 | 6.350×10-3 | — | — |

| 总和Cor total | 0.936 | 32 | — | — | — |

表5 Box-Behnken Design试验方差分析结果

Table 5 Analysis result of variance for the Box-Behnken Design experiment

| 方差来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方差 Mean square | F值 F value | p |

|---|---|---|---|---|---|

| 模型Model | 0.430 | 9 | 0.048 | 7.100 | 0.008 5 |

| F | 0.039 | 1 | 0.039 | 5.780 | 0.047 2 |

| I | 0.070 | 1 | 0.070 | 10.250 | 0.015 0 |

| H | 5.000×10-5 | 1 | 5.000×10-5 | 7.368×10-3 | 0.934 0 |

| FI | 0.045 | 1 | 0.045 | 6.620 | 0.036 8 |

| FH | 5.551×10-17 | 1 | 5.551×10-17 | 8.180×10-15 | 1.000 0 |

| IH | 1.000×10-4 | 1 | 1.000×10-4 | 0.015 | 0.906 8 |

| F2 | 0.025 | 1 | 0.025 | 0.680 | 0.096 4 |

| I2 | 0.220 | 1 | 0.220 | 0.120 | 0.000 7 |

| H2 | 0.012 | 1 | 0.012 | 1.810 | 0.220 2 |

| 残差Residual | 0.048 | 7 | 6.787×10-3 | — | — |

| 失拟项Lack of fit | 0.022 | 3 | 7.368×10-3 | 1.160 | 0.428 0 |

| 纯误差Pure error | 0.025 | 4 | 6.350×10-3 | — | — |

| 总和Cor total | 0.936 | 32 | — | — | — |

| [1] | CHEN Y J, ZENG L, SHU N, et al. Pestalotiopsis-like species causing gray blight disease on Camellia sinensis in China[J]. Plant Disease, 2018, 102(1): 98-106. |

| [2] | PANDEY A K, SINNIAH G D, BABU A, et al. How the global tea industry copes with fungal diseases-challenges and opportunities[J]. Plant Disease, 2021, 105(7): 1868-1879. |

| [3] | KUMAR J, RAMLAL A, MALLICK D, et al. An overview of some biopesticides and their importance in plant protection for commercial acceptance[J]. Plants, 2021, 10(6): 1185. |

| [4] | 黄大野, 杨丹, 姚经武, 等. 贝莱斯芽孢杆菌CY30防治茶轮斑病研究[J]. 中国植保导刊, 2020, 40(11): 13-18. |

| HUANG D Y, YANG D, YAO J W, et al. Study on the control effect of Bacillus velezensis CY30 on tea gray blight[J]. China Plant Protection, 2020, 40(11): 13-18. (in Chinese) | |

| [5] | 糜芳, 吴紫燕, 王承芳, 等. 1株解淀粉芽孢杆菌的分离、鉴定及在马铃薯疮痂病防治上的应用[J]. 江苏农业科学, 2021, 49(18): 122-127. |

| MI F, WU Z Y, WANG C F, et al. Isolation and identification of a strain of Bacillus amyloliquefaciens and its application in prevention and treatment of potato scab[J]. Jiangsu Agricultural Sciences, 2021, 49(18): 122-127. (in Chinese with English abstract) | |

| [6] | 杨学宇, 谭琳, 张玉丹, 等. 茶轮斑病病原菌的分离鉴定及其拮抗菌筛选[J]. 湖南农业大学学报(自然科学版), 2023, 49(2): 195-200. |

| YANG X Y, TAN L, ZHANG Y D, et al. Identification of pathogen from tea leaves with gray blight disease and screening of biocontrol strain biocontrol strain[J]. Journal of Hunan Agricultural University(Natural Sciences), 2023, 49(2): 195-200. (in Chinese with English abstract) | |

| [7] | 马乔女, 李心悦, 顾欣, 等. 芽孢杆菌抗真菌肽的研究进展[J]. 中国植保导刊, 2023, 43(5): 17-24. |

| MA Q N, LI X Y, GU X, et al. Research progress of Bacillus antifungal peptides[J]. China Plant Protection, 2023, 43(5): 17-24. (in Chinese) | |

| [8] | MULATU A, ALEMU T, MEGERSA N, et al. Optimization of culture conditions and production of bio-fungicides from Trichoderma species under solid-state fermentation using mathematical modeling[J]. Microorganisms, 2021, 9(8): 1675. |

| [9] | ZALILA-KOLSI I, KESSENTINI S, TOUNSI S, et al. Optimization of Bacillus amyloliquefaciens BLB369 culture medium by response surface methodology for low cost production of antifungal activity[J]. Microorganisms, 2022, 10(4): 830. |

| [10] | 李姝江, 王淋敏, 谯天敏, 等. 利用响应面法优化贝莱斯芽孢杆菌ZJ20发酵参数[J]. 西北农林科技大学学报(自然科学版), 2019, 47(2): 88-96. |

| LI S J, WANG L M, QIAO T M, et al. Optimization of Bacillus velezensis ZJ20 fermentation parameters by response surface methodology[J]. Journal of Northwest A & F University(Natural Science Edition), 2019, 47(2): 88-96. (in Chinese with English abstract) | |

| [11] | 施兆荣, 孙述俊, 张广荣, 等. 甜瓜黑斑病菌的拮抗细菌筛选、鉴定及发酵条件优化[J]. 生物技术通报, 2022, 38(1): 115-124. |

| SHl Z R, SUN S J, ZHANG G R, et al. Screening, identification and fermentation condition optimization of an antagonistic bacterium for melon black spot[J]. Biotechnology Bulletin, 2022, 38(1): 115-124. (in Chinese with English abstract) | |

| [12] | LIU Q, SHEN Y R, YIN K D. Optimized production of protein elicitor AMEP412 by Bacillus subtilis BU412 through response surface methodology[J]. Biotechnology & Biotechnological Equipment, 2021, 35(1): 1058-1064. |

| [13] | 陈越, 李虎林, 闫寒, 等. 烟草炭疽病拮抗菌分离及其发酵条件优化[J]. 吉林农业大学学报, 2020, 42(5): 518-525. |

| CHEN Y, LI H L, YAN H, et al. Isolation of antagonistic bacteria against tobacco anthracnose and optimization of fermentation conditions[J]. Journal of Jilin Agricultural University, 2020, 42(5): 518-525. (in Chinese with English abstract) | |

| [14] | 刘仕飞, 伊艳杰, 董臣, 等. 禾谷丝核菌拮抗细菌XZ18-3的分离、鉴定及其发酵条件优化[J]. 中国植保导刊, 2019, 39(11): 5-13. |

| LIU S F, YI Y J, DONG C, et al. Isolation and identification of antagonistic bacteria against Rhizoctonia cerealis and optimization of its fermentation conditions[J]. China Plant Protection, 2019, 39(11): 5-13. (in Chinese) | |

| [15] | 石慧敏, 叶建仁, 王焱, 等. 响应面优化贝莱斯芽孢杆菌(Bacillus velezensis)菌株YH-18产芽孢培养基和培养条件[J]. 南京林业大学学报(自然科学版), 2023, 47(1): 209-218. |

| SHI H M, YE J R, WANG Y, et al. Optimizing spore-producing medium and culture conditions of Bacillus velezensis strain YH-18 by response surface methodology[J]. Journal of Nanjing Forestry University(Natural Sciences Edition), 2023, 47(1): 209-218. (in Chinese with English abstract) | |

| [16] | 王垚, 黄纯杨, 杨亮, 等. 烟草青枯病复配增效药剂筛选及田间防效[J]. 农药, 2022, 61(10): 776-80. |

| WANG Y, HUANG C Y, YANG L, et al. Selection on synergetic ratio of combine pesticides to tobacco bacterial wilt and their field control effect[J]. Agrochemicals, 2022, 61(10): 776-80. (in Chinese) | |

| [17] | 李书颖, 朱天辉. 响应面法优化杜仲黑斑病菌生防芽胞杆菌的发酵参数[J]. 植物保护, 2020, 46(5): 133-141. |

| LI S Y, ZHU T H. Optimization of fermentation parameters of Bacillus amyloliquefaciens against Pestalotiopsis trachicarpicola by using response surface methodology[J]. Plant Protection, 2020, 46(5): 133-141. (in Chinese with English abstract) | |

| [18] | 金黎明, 王晓彤, 宫小明, 等. 拮抗黄曲霉枯草芽孢杆菌21-1-2发酵条件的优化[J]. 中国酿造, 2020, 39(3): 47-51. |

| JIN L M, WANG X T, GONG X M, et al. Optimization of fermentation conditions of Bacillus subtilis 21-1-2 against Aspergillus flavus[J]. China Brewing, 2020, 39(3): 47-51. (in Chinese with English abstract) | |

| [19] | 马金秀, 张锦锋, 王江来, 等. 普城沙雷氏菌MM产酶条件优化及对西瓜枯萎病的防治效果[J]. 西北农业学报, 2022, 31(12): 1635-1645. |

| MA J X, ZHANG J F, WANG J L, et al. Optimization of enzyme production conditions of Serratia plymuthica MM and its control effect on watermelon Fusarium wilt[J]. Acta Agriculturae Boreali-occidentalis Sinica, 2022, 31(12): 1635-1645. (in Chinese with English abstract) | |

| [20] | 郑世仲, 周子维, 陈晓慧, 等. 拮抗炭疽病的茶树内生菌筛选、鉴定及培养条件优化[J]. 茶叶科学, 2023, 43(2): 205-215. |

| ZHENG S Z, ZHOU Z W, CHEN X H, et al. Screening, identification and culture condition optimization of antagonistic endophytic bacteria against Gloeosporium theae-sinensis Miyake[J]. Journal of Tea Science, 2023, 43(2): 205-215. (in Chinese with English abstract) | |

| [21] | 杜丽红, 郝亚男, 陈宁, 等. 有机氮源及其在微生物发酵中的应用[J]. 发酵科技通讯, 2019, 48(1): 1-4. |

| DU L H, HAO Y N, CHEN N, et al. Organic nitrogen source and their applications in microbial fermentation[J]. Bulletin of Fermentation Science and Technology, 2019, 48(1): 1-4. (in Chinese with English abstract) | |

| [22] | 梁艳琼, 吴伟怀, 习金根, 等. 解淀粉芽胞杆菌JNC2摇瓶发酵条件优化[J]. 草业科学, 2019, 36(8): 2159-2167. |

| LIANG Y Q, WU W H, Ⅺ J G, et al. Optimizing fermentation condition for Bacillus amyloliquefaciens JNC2 in flask[J]. Pratacultural Science, 2019, 36(8): 2159-2167. (in Chinese with English abstract) | |

| [23] | 卢彩鸽, 董红平, 张殿朋, 等. 解淀粉芽胞杆菌MH71摇瓶发酵培养基及发酵条件优化[J]. 中国生物防治学报, 2015, 31(3): 369-377. |

| LU C G, DONG H P, ZHANG D P, et al. Optimization of fermentation medium components and cultural conditions for Bacillus amyloliquefaciens MH71 in flask[J]. Chinese Journal of Biological Control, 2015, 31(3): 369-377. (in Chinese with English abstract) | |

| [24] | 郭建军, 曾静, 袁林, 等. 响应面法优化多粘类芽孢杆菌LY1的产芽孢条件[J]. 湖南农业科学, 2022(4): 6-11. |

| GUO J J, ZENG J, YUAN L, et al. Optimization of spore production conditions of Paenibacillus polymyxa LY1 by response surface methodology[J]. Hunan Agricultural Sciences, 2022(4): 6-11. (in Chinese with English abstract) | |

| [25] | 汤永玉, 吴国星, 李冉, 等. 响应面法优化爪哇虫草菌的培养条件及其对斜纹夜蛾的毒力和保护酶活性影响[J]. 微生物学报, 2023, 63(12): 4555-4573. |

| TANG Y Y, WU G X, LI R, et al. Response surface methodology-based optimization of culture conditions of Cordyceps javanica with effects on virulence and protective enzyme activity of Spodoptera litura[J]. Acta Microbiologica Sinica, 2023, 63(12): 4555-4573. (in Chinese with English abstract) | |

| [26] | 刘芳, 黎妍妍, 陈伟, 等. 响应面法优化贝莱斯芽胞杆菌YC11的液体发酵培养基[J]. 中国生物防治学报, 2023, 39 (4): 915-923. |

| LIU F, LI Y Y, CHEN W, et al. Optimization of fermentation medium for spore production by Bacillus velezensis YC11 through response-surface methodology[J]. Chinese Journal of Biological Control, 2023, 39 (4): 915-923. (in Chinese with English abstract) | |

| [27] | 薛锐, 沈绍运, 邓细周, 等. 响应面法优化莱氏绿僵菌SL200714菌株液态发酵培养条件[J]. 中国农学通报, 2023, 39(6): 135-143. |

| XUE R, SHEN S Y, DENG X Z, et al. Metarhizium rileyi SL200714 strain liquid fermentation conditions: optimization by response surface methodology[J]. Chinese Agricultural Science Bulletin, 2023, 39(6): 135-143. (in Chinese with English abstract) | |

| [28] | 薛锐, 付玉飞, 杨光源, 等. 响应面设计优化莱氏绿僵菌SZCY固体发酵培养条件及致病力测定[J]. 微生物学通报, 2023, 50 (2): 514-525. |

| XUE R, FU Y F, YANG G Y, et al. Optimization of the solid-state fermentation conditions of Metarhizium rileyi SZCY by response surface methodology and determination of the virulence[J]. Microbiology China, 2023, 50 (2): 514-525. (in Chinese with English abstract) | |

| [29] | 夏邦华, 赵健, 宫娉, 等. 基于响应面分析法优化解淀粉芽孢杆菌DSYZ发酵条件[J]. 山东农业大学学报(自然科学版), 2021, 52(2): 241-246. |

| XIA B H, ZHAO J, GONG P, et al. Optimal fermentation conditions for Bacillus amyloliquefaciens DSYZ based on response surface methodology[J]. Journal of Shandong Agricultural University(Natural Science Edition), 2021, 52(2): 241-246. (in Chinese with English abstract) |

| [1] | 罗阳兰, 黄丽玲, 黄世旅, 阎勇, 王灿琴. 羊肚菌WSJD-1的基质配方优化及其在广西地区的栽培技术[J]. 浙江农业学报, 2025, 37(9): 1881-1890. |

| [2] | 周毛措, 卢建雄, 郭晓农, 冯玉兰, 柴薇薇, 高鹏飞. 基于响应面法优化藜麦秸秆发酵工艺[J]. 浙江农业学报, 2024, 36(9): 2020-2030. |

| [3] | 曹乃馨, 罗阳兰, 阎勇, 解修超, 张雯龙. 桑树桑黄JM-1胞外多糖液态培养基优化及其抗氧化性研究[J]. 浙江农业学报, 2024, 36(6): 1245-1255. |

| [4] | 龚娜, 刘国丽, 陈珣, 马晓颖, 肇莹, 肖军. 一株野生肺形侧耳的鉴定及其液体发酵培养基的优化[J]. 浙江农业学报, 2024, 36(11): 2535-2545. |

| [5] | 张璐, 李翘楚, 王增利, 丁强, 王鸿磊. 金耳类酵母型菌株分离与高产胞外多糖培养基优化[J]. 浙江农业学报, 2023, 35(5): 1154-1160. |

| [6] | 王海基, 王敏, 卢勇涛, 营雨琨, 王吉亮, 薛理, 秦朝民, 何玉泽. 弹齿链耙式残膜回收机链耙装置的设计与试验[J]. 浙江农业学报, 2023, 35(10): 2465-2476. |

| [7] | 杨叶爽, 张映萍, 陈伊凡, 张晋, 李欢欢, 陈黎洪, 唐宏刚, 高斌. 响应面法优化复配蛋液配方[J]. 浙江农业学报, 2022, 34(1): 153-162. |

| [8] | 姜兴粲, 李冰, 杨敏, 张继瑜. 响应面法优化沙拉沙星/β-环糊精包合物制备工艺与稳定性评价[J]. 浙江农业学报, 2021, 33(3): 404-412. |

| [9] | 岳登高, 程亮, 郭青云. 出芽短梗霉菌PA-2脂肽类物质抑菌活性及其发酵条件优化[J]. 浙江农业学报, 2021, 33(3): 479-489. |

| [10] | 沈植国, 孙萌, 丁鑫, 程建明, 陈迪新. 不同培养基组分对5个蜡梅品系花粉萌发和花粉管生长的影响[J]. 浙江农业学报, 2021, 33(2): 278-287. |

| [11] | 程安东, 汪本勤. 金寨县桑黄的菌种鉴定与生长特性研究[J]. 浙江农业学报, 2021, 33(12): 2234-2244. |

| [12] | 杨志, 李文义, 高云涛, 熊华斌, 陈毅坚, 杨慧娟. 响应面法优化针叶樱桃总黄酮的提取工艺及其抗氧化活性研究[J]. 浙江农业学报, 2020, 32(10): 1866-1872. |

| [13] | 江林娟, 邹雪, 黄雪丽, 倪苏, 李立芹, 杨世民. 响应面法优化马铃薯茎段高效再生体系[J]. 浙江农业学报, 2018, 30(6): 918-925. |

| [14] | 温慧萍, 肖建中, 雷伟敏, 纪佳娜. HPLC结合响应面法优化柳叶蜡梅总黄酮提取工艺及其抑菌活性研究[J]. 浙江农业学报, 2018, 30(2): 298-306. |

| [15] | 王储炎, 程俊文, 祝超. 黑芝菌发酵产生胞外多糖的工艺优化及其抗氧化活性[J]. 浙江农业学报, 2018, 30(11): 1938-1945. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||