浙江农业学报 ›› 2026, Vol. 38 ›› Issue (1): 184-196.DOI: 10.3969/j.issn.1004-1524.20240750

• 综述 • 上一篇

果园采摘机械的研究现状与发展趋势

汤志永1,2,3( ), 何义川1,4,*(

), 何义川1,4,*( ), 汤智辉2,3, 张超5, 刘湛1,2,3, 刘晓瑜1,2,3

), 汤智辉2,3, 张超5, 刘湛1,2,3, 刘晓瑜1,2,3

- 1.塔里木大学 机械电气化工程学院,新疆 阿拉尔 843300

2.南疆特色农林产物利用与装备兵团重点实验室,新疆 阿拉尔 843300

3.新疆维吾尔自治区教育厅普通高等学校现代农业工程重点实验室,新疆 阿拉尔 843300

4.华中农业大学 工学院,湖北 武汉 430070

5.新疆生产建设兵团农机技术推广总站,新疆 乌鲁木齐 830002

-

收稿日期:2024-08-22出版日期:2026-01-25发布日期:2026-02-11 -

作者简介:何义川,E-mail:hyc2003@163.com

汤志永,研究方向为林果机械。E-mail:1530129576@qq.com -

通讯作者:何义川 -

基金资助:新疆生产建设兵团科技计划(2024BA005);新疆生产建设兵团科技计划(2021AA005);新疆维吾尔自治区地方标准制(修)订计划项目(XJ23-147);师市科技攻关计划项目(2023GG2201)

Research status and development trend of orchard picking machinery

TANG Zhiyong1,2,3( ), HE Yichuan1,4,*(

), HE Yichuan1,4,*( ), TANG Zhihui2,3, ZHANG Chao5, LIU Zhan1,2,3, LIU Xiaoyu1,2,3

), TANG Zhihui2,3, ZHANG Chao5, LIU Zhan1,2,3, LIU Xiaoyu1,2,3

- 1. College of Mechanical and Electrical Engineering, Tarim University, Aral 843300, Xinjiang, China

2. Xinjiang Production and Construction Corps(XPCC)Key Laboratory of Utilization and Equipment of Special Agricultural and Forestry Products in Southern Xinjiang, Aral 843300, Xinjiang, China

3. Modern Agricultural Engineering Key Laboratory at Universities of Education Department of Xinjiang Uygur Autonomous Region, Aral 843300, Xinjiang, China

4. College of Engineering, Huazhong Agricultural University, Wuhan 430070, China

5. Center of Agricultural Machinery Extension of Xinjiang Production and Construction Corps, Urumqi 830002, China

-

Received:2024-08-22Online:2026-01-25Published:2026-02-11 -

Contact:HE Yichuan

摘要:

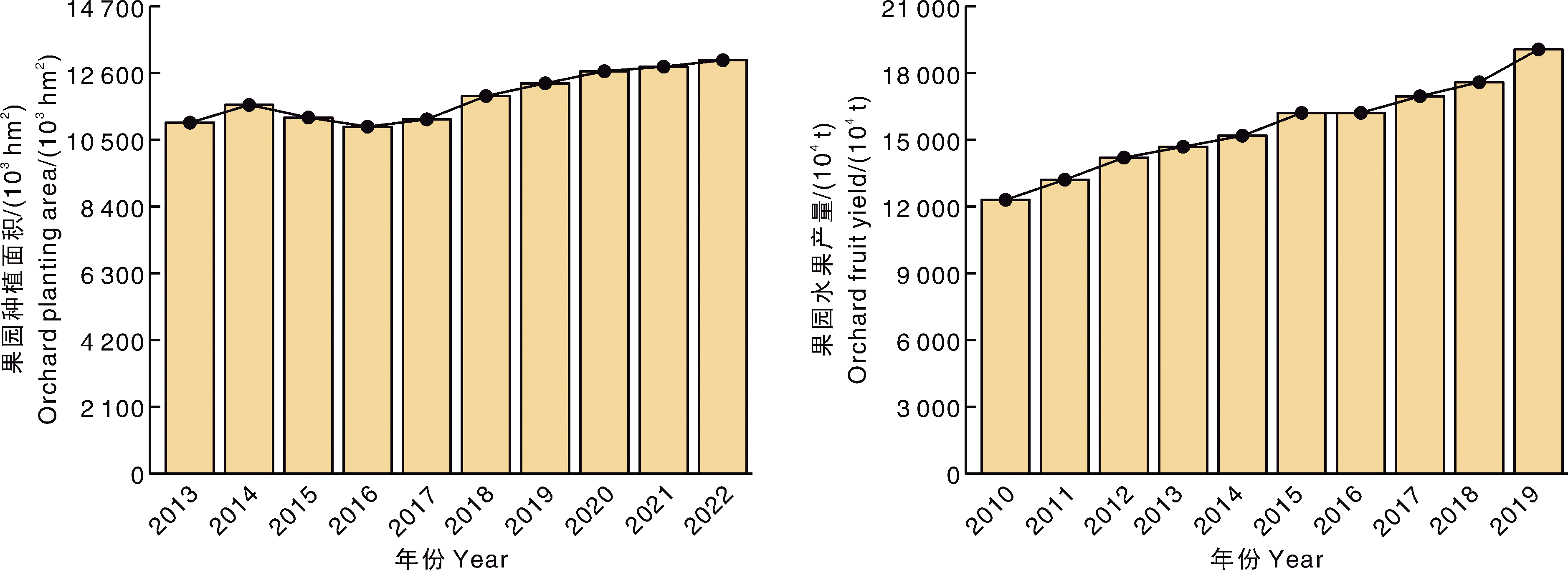

随着农业现代化进程加快,传统人工采摘方式难以满足市场需求,发展机械化采摘技术成为我国果园农业现代化的必然趋势。果园采摘机械的研究与开发对提升采摘效率、降低采摘成本具有重要意义。文章系统论述了果园机械化采摘技术的意义,分析了果园采摘机械的分类与特性,综述了国内外半机械化辅助采摘设备与全机械化采摘机器人的发展历程、现状及特点。同时,结合我国主要果树种植模式、水果种类及种植面积等背景,指出了当前果园采摘机械面临的问题与制约因素,并对未来发展趋势进行了展望,以期为我国果园采摘机械的改进与发展提供参考。

中图分类号:

引用本文

汤志永, 何义川, 汤智辉, 张超, 刘湛, 刘晓瑜. 果园采摘机械的研究现状与发展趋势[J]. 浙江农业学报, 2026, 38(1): 184-196.

TANG Zhiyong, HE Yichuan, TANG Zhihui, ZHANG Chao, LIU Zhan, LIU Xiaoyu. Research status and development trend of orchard picking machinery[J]. Acta Agriculturae Zhejiangensis, 2026, 38(1): 184-196.

| 水果种类 Fruit type | 种植面积/(103 hm2) Planting area/(103 hm2) | 产量/104 t Yield/104 t |

|---|---|---|

| 香蕉Banana | 326.85 | 1 177.68 |

| 苹果Apple | 1 955.77 | 4 757.18 |

| 柑橘Citrus | 2 995.81 | 6 003.89 |

| 梨Pear | 914.97 | 1 926.53 |

| 葡萄Grape | 705.11 | 1 537.79 |

表1 2022年我国果园主要水果的种植面积和产量

Table 1 The planting area and yield of major fruits in orchards in China in 2022

| 水果种类 Fruit type | 种植面积/(103 hm2) Planting area/(103 hm2) | 产量/104 t Yield/104 t |

|---|---|---|

| 香蕉Banana | 326.85 | 1 177.68 |

| 苹果Apple | 1 955.77 | 4 757.18 |

| 柑橘Citrus | 2 995.81 | 6 003.89 |

| 梨Pear | 914.97 | 1 926.53 |

| 葡萄Grape | 705.11 | 1 537.79 |

| 采摘方式 Picking methods | 优点 Advantage | 缺点 Shortcoming |

|---|---|---|

| 振摇式 Shake | 适合果皮果肉较硬的水果种类 Suitable for fruit types with hard peel and flesh | 会降低采摘品质,不适宜鲜水果 Will reduce picking quality, not suitable for fresh fruit |

| 撞击式 Percussive | 适用于果皮果肉较硬或树干较大的果树 Suitable for fruit trees with hard rinds and flesh or with large stems | 采摘造成损伤率过高,对果树损伤较大 Harvesting causes excessive damage rates and greater damage to fruit trees |

| 切割式 Cut | 对果树枝条损伤率较低,操作方便省时省力 Low damage rate to fruit tree branches, easy to operate and save time and labour | 采摘作业效率低,具有一定危险性 Picking operations are inefficient and hazardous |

| 采摘作业平台 Picking platform | 自动化程度较高,研制成本低,作业效率高 High degree of automation, low development costs and high operational efficiency | 创新性较低,人机结合性较差,作业环境有局限性 Less innovative, less human-machine integration, limited operating environment |

表2 半机械化辅助人工采摘方式对比

Table 2 Comparison of semi-mechanized assisted manual harvesting methods

| 采摘方式 Picking methods | 优点 Advantage | 缺点 Shortcoming |

|---|---|---|

| 振摇式 Shake | 适合果皮果肉较硬的水果种类 Suitable for fruit types with hard peel and flesh | 会降低采摘品质,不适宜鲜水果 Will reduce picking quality, not suitable for fresh fruit |

| 撞击式 Percussive | 适用于果皮果肉较硬或树干较大的果树 Suitable for fruit trees with hard rinds and flesh or with large stems | 采摘造成损伤率过高,对果树损伤较大 Harvesting causes excessive damage rates and greater damage to fruit trees |

| 切割式 Cut | 对果树枝条损伤率较低,操作方便省时省力 Low damage rate to fruit tree branches, easy to operate and save time and labour | 采摘作业效率低,具有一定危险性 Picking operations are inefficient and hazardous |

| 采摘作业平台 Picking platform | 自动化程度较高,研制成本低,作业效率高 High degree of automation, low development costs and high operational efficiency | 创新性较低,人机结合性较差,作业环境有局限性 Less innovative, less human-machine integration, limited operating environment |

| 区别 Distinction | 农业机器人 Agricultural robots | 工业机器人 Industrial robots |

|---|---|---|

| 工作场景 Working environment | 工作场景多变,具有随机性,受环境因素影响较大 Work scenarios are variable, random and influenced by environmental factors | 工作场景单一,不受环境影响 Single working scenario, independent of the environment |

| 工作量大小 Size of workload | 作业目标不固定,需不断判断并计算路线、作业动作等 The target of the operation is not fixed, and constant judgement and calculation of the route and operation actions are required | 作业动作单一,重复程度高 Single action and high repetition of work |

| 构造设计 Tectonic design | 构造设计复杂,需要较高的灵活度 The structural design is complex and requires a high degree of flexibility | 只做简单运动,固定不变 Simple movements only, fixed |

表3 农业机器人与工业机器人区别

Table 3 The difference between agricultural robots and industrial robots

| 区别 Distinction | 农业机器人 Agricultural robots | 工业机器人 Industrial robots |

|---|---|---|

| 工作场景 Working environment | 工作场景多变,具有随机性,受环境因素影响较大 Work scenarios are variable, random and influenced by environmental factors | 工作场景单一,不受环境影响 Single working scenario, independent of the environment |

| 工作量大小 Size of workload | 作业目标不固定,需不断判断并计算路线、作业动作等 The target of the operation is not fixed, and constant judgement and calculation of the route and operation actions are required | 作业动作单一,重复程度高 Single action and high repetition of work |

| 构造设计 Tectonic design | 构造设计复杂,需要较高的灵活度 The structural design is complex and requires a high degree of flexibility | 只做简单运动,固定不变 Simple movements only, fixed |

图2 采摘作业平台 从左到右依次为自走式果园作业平台、D060履带式果园作业平台、3GYP-500果园作业平台和新型自动调平作业平台。

Fig.2 Picking platform From left to right are the self-propelled orchard operation platform, D060 crawler orchard operation platform, 3GYP-500 orchard operation platform and a new type of automatic leveling platform.

| 不同成熟期 Different maturation periods | 果梗切断力Fruit stalk cutting force | ||||||

|---|---|---|---|---|---|---|---|

| 番茄Tomato | 柑橘Citrus | 茄子Eggplant | 鲜梨Fresh pear | 黄瓜Cucumber | 猕猴桃Kiwifruit | 苹果Apple | |

| 青果期Green fruit period | 21.89 | 17.73 | 28.05 | 12.31 | 17.70 | 10.33 | 11.62 |

| 绿熟期Green ripening period | 22.40 | 19.60 | 29.82 | 12.73 | 18.32 | 10.73 | 12.03 |

| 初熟期First maturity period | 22.99 | 25.32 | 30.07 | 13.69 | 18.67 | 11.02 | 12.37 |

| 半熟期Semi-ripe period | 23.71 | 32.77 | 34.29 | 13.90 | 20.07 | 11.66 | 12.79 |

表4 不同成熟期果实的果梗切断力

Table 4 Fruit stalk cutting force at different maturity stages N

| 不同成熟期 Different maturation periods | 果梗切断力Fruit stalk cutting force | ||||||

|---|---|---|---|---|---|---|---|

| 番茄Tomato | 柑橘Citrus | 茄子Eggplant | 鲜梨Fresh pear | 黄瓜Cucumber | 猕猴桃Kiwifruit | 苹果Apple | |

| 青果期Green fruit period | 21.89 | 17.73 | 28.05 | 12.31 | 17.70 | 10.33 | 11.62 |

| 绿熟期Green ripening period | 22.40 | 19.60 | 29.82 | 12.73 | 18.32 | 10.73 | 12.03 |

| 初熟期First maturity period | 22.99 | 25.32 | 30.07 | 13.69 | 18.67 | 11.02 | 12.37 |

| 半熟期Semi-ripe period | 23.71 | 32.77 | 34.29 | 13.90 | 20.07 | 11.66 | 12.79 |

| 运动形式 Athletic forms | 坐标构成 Coordinate composition | 工作空间 Workspace | 所占空间 Space occupied | 控制难度 Control the difficulty | 典型代表 Typical representatives |

|---|---|---|---|---|---|

| SCARA型 SCARA type | 3R和1P 3R and 1P | 半圆柱体 Half cylinder | 较小 Smaller | 难 Difficult | SCARA装配机器人 SCARA assembly robot |

| 关节坐标型 Joint coordinates type | 3R | 球缺形 The ball is out of shape | 最小 Least | 较难 Harder | MOTOMAN机器人 MOTOMAN robot |

| 直角坐标型 Cartesian coordinates type | 3P | 矩形六面体 Rectangular hexahedron | 最大 Most | 容易 Easy | 龙门机器人 Gantry robot |

| 球坐标型 Spherical coordinates type | 1P和2R 1P and 2R | 空心开口截锥体 Hollow open truncated cone | 较小 Smaller | 难 Difficult | Unimate机器人 Unimate robot |

| 圆柱坐标型 Cylindrical coordinate type | 2P和1R 2P and 1R | 开口空心圆柱体 Open hollow cylinder | 较大 Larger | 较容易 Easier | Versatran机器人 Versatran robot |

表5 五种坐标系型式对比

Table 5 Comparison of five coordinate system types

| 运动形式 Athletic forms | 坐标构成 Coordinate composition | 工作空间 Workspace | 所占空间 Space occupied | 控制难度 Control the difficulty | 典型代表 Typical representatives |

|---|---|---|---|---|---|

| SCARA型 SCARA type | 3R和1P 3R and 1P | 半圆柱体 Half cylinder | 较小 Smaller | 难 Difficult | SCARA装配机器人 SCARA assembly robot |

| 关节坐标型 Joint coordinates type | 3R | 球缺形 The ball is out of shape | 最小 Least | 较难 Harder | MOTOMAN机器人 MOTOMAN robot |

| 直角坐标型 Cartesian coordinates type | 3P | 矩形六面体 Rectangular hexahedron | 最大 Most | 容易 Easy | 龙门机器人 Gantry robot |

| 球坐标型 Spherical coordinates type | 1P和2R 1P and 2R | 空心开口截锥体 Hollow open truncated cone | 较小 Smaller | 难 Difficult | Unimate机器人 Unimate robot |

| 圆柱坐标型 Cylindrical coordinate type | 2P和1R 2P and 1R | 开口空心圆柱体 Open hollow cylinder | 较大 Larger | 较容易 Easier | Versatran机器人 Versatran robot |

| [1] | 孔德晨. 越来越多进口水果摆上“中国果盘”[N]. 人民日报海外版, 2023-06-28( 11). |

| [2] | 骆爱学. 小型果树采摘机改良设计的研究[D]. 天津: 天津科技大学, 2019. |

| LUO A X. Research on improved design of small fruit picking machine[D]. Tianjin: Tianjin University of Science & Technology, 2019. | |

| [3] | 中华人民共和国统计局. 中国统计年鉴2023[M]. 北京: 中国统计出版社, 2023. |

| [4] | 苑严伟, 白圣贺, 牛康, 等. 林果机械化采收技术与装备研究进展[J]. 农业工程学报, 2022, 38(9): 53-63. |

| YUAN Y W, BAI S H, NIU K, et al. Research progress on mechanized harvesting technology and equipment for forest fruit[J]. Transactions of the Chinese Society of Agricultural Engineering, 2022, 38(9): 53-63. | |

| [5] | 牛艺达. 水果采摘机器人机械臂采摘方便度评价方法的研究[D]. 雅安: 四川农业大学, 2021. |

| NIU Y D. Study on evaluation method of picking convenience of fruit picking robot manipulator[D]. Ya’an: Sichuan Agricultural University, 2021. | |

| [6] | 姬江涛, 郑治华, 杜蒙蒙, 等. 农业机器人的发展现状及趋势[J]. 农机化研究, 2014, 36(2): 1-4. |

| JI J T, ZHENG Z H, DU M M, et al. Development status and trend of agricultural robots[J]. Journal of Agricultural Mechanization Research, 2014, 36(2): 1-4. | |

| [7] | 许成杰, 孔斌, 夏飞, 等. 重庆市果园采摘机械化发展现状及展望[J]. 南方农机, 2021, 52(10): 64-66. |

| XU C J, KONG B, XIA F, et al. Present situation and prospect of orchard picking mechanization in Chongqing[J]. China Southern Agricultural Machinery, 2021, 52(10): 64-66. | |

| [8] | 孙邦明. 我国薄壳山核桃产业的现状、问题与未来展望[J]. 基层农技推广, 2023, 11(10): 112-115. |

| SUN B M. Present situation, problems and future prospect of Carya illinoensis industry in China[J]. Primary Agricultural Technology Extension, 2023, 11(10): 112-115. | |

| [9] | 尹许超. 樱桃采摘机优化设计与试验研究[D]. 沈阳: 沈阳农业大学, 2023. |

| YIN X C. Optimization design and experimental study of cherry picker[D]. Shenyang: Shenyang Agricultural University, 2023. | |

| [10] | 范子彦. 推摇式油茶果采摘机执行机构控制技术研究[D]. 长沙: 中南林业科技大学, 2022. |

| FAN Z Y. Research on the control technology of the actuating mechanism of the push-and-shake Camellia fruit picking machine[D]. Changsha: Central South University of Forestry & Technology, 2022. | |

| [11] | 范晓文. 苹果多工位低损收获系统仿真研究[D]. 保定: 河北农业大学, 2020. |

| FAN X W. Simulation study on multi-station and low-damage harvesting system used for apples[D]. Baoding: Hebei Agricultural University, 2020. | |

| [12] | 段洁利, 陆华忠, 王慰祖, 等. 水果采收机械的现状与发展[J]. 广东农业科学, 2012, 39(16): 189-192. |

| DUAN J L, LU H Z, WANG W Z, et al. Present situation and development of the fruit harvesting machinery[J]. Guangdong Agricultural Sciences, 2012, 39(16): 189-192. | |

| [13] | 吕怡秋, 杨叶. 我国果园机械采摘与分级研究进展[J]. 农村实用技术, 2020(10): 107-108. |

| LYU Y Q, YANG Y. Research progress on mechanical picking and grading of orchards in China[J]. Nongcun Shiyong Jishu, 2020(10): 107-108. | |

| [14] | 李会宾, 史云. 果园采摘机器人研究综述[J]. 中国农业信息, 2019, 31(6): 1-9. |

| LI H B, SHI Y. Review on orchard harvesting robots[J]. China Agricultural Informatics, 2019, 31(6): 1-9. | |

| [15] | 杨云磊, 张秀花, 于洋, 等. 果园采摘平台研究现状及发展趋势[J]. 河北农机, 2024(1): 5-8. |

| YANG Y L, ZHANG X H, YU Y, et al. Research status and development trend of orchard picking platform[J]. Hebei Farm Machinery, 2024(1): 5-8. | |

| [16] | 刘梦飞. 核桃采摘机的设计与试验[D]. 西安: 陕西科技大学, 2015. |

| LIU M F. Walnut picking machine design and experiment[D]. Xi’an: Shanxi University of Science & Technology, 2015. | |

| [17] | 刘伟起. 履带式果园作业平台结构优化设计与稳定性研究[D]. 保定: 河北农业大学, 2022. |

| LIU W Q. Structure optimization design and stability research of caterpillar orchard working platform[D]. Baoding: Hebei Agricultural University, 2022. | |

| [18] | 陈度, 杜小强, 王书茂, 等. 振动式果品收获技术机理分析及研究进展[J]. 农业工程学报, 2011, 27(8): 195-200. |

| CHEN D, DU X Q, WANG S M, et al. Mechanism of vibratory fruit harvest and review of current advance[J]. Transactions of the Chinese Society of Agricultural Engineering, 2011, 27(8): 195-200. | |

| [19] | 李松涛. 基于旋轮线轨迹的果品振动采收机构设计与优化[D]. 杭州: 浙江理工大学, 2019. |

| LI S T. Design and optimization of fruit vibration harvesting mechanism based on epitrochoid[D]. Hangzhou: Zhejiang Sci-Tech University, 2019. | |

| [20] | 陈翊栋, 刘轶. 果树气动剪枝机工作原理及现状[J]. 农业机械, 2008(25): 54-56. |

| CHEN Y D, LIU Y. Working principle and present situation of pneumatic pruning machine for fruit trees[J]. Farm Machinery, 2008(25): 54-56. | |

| [21] | 张松, 赵彦喆, 姜星冶, 等. 多功能模块化水果采摘器设计[J]. 吉林工程技术师范学院学报, 2019, 35(12): 104-106. |

| ZHANG S, ZHAO Y Z, JIANG X Y, et al. A multifunctional modularized fruit collector[J]. Journal of Jilin Teachers Institute of Engineering and Technology, 2019, 35(12): 104-106. | |

| [22] | 谢豪. 油茶果采收机行走控制系统设计与性能测试[D]. 长沙: 中南林业科技大学, 2023. |

| XIE H. Design and performance test of Camellia fruit harvester walking control system[D]. Changsha: Central South University of Forestry & Technology, 2023. | |

| [23] | 杨光, 张长青, 谭宏利, 等. 林果采摘设备现状与发展方向[J]. 林业和草原机械, 2020, 1(2): 39-41. |

| YANG G, ZHANG C Q, TAN H L, et al. Present situation and development direction of forest fruit picking equipment[J]. Forestry and Grassland Machinery, 2020, 1(2): 39-41. | |

| [24] | 王亚龙. 牵引式果园采摘作业平台设计与研究[D]. 杨凌: 西北农林科技大学, 2017. |

| WANG Y L. Design and research on tractive orchard picking platform[D]. Yangling: Northwest A & F University, 2017. | |

| [25] | 韩东亚. 苹果采摘机器人设计与研究[D]. 兰州: 兰州理工大学, 2023. |

| HAN D Y. Design and research of apple picking robot[D]. Lanzhou: Lanzhou University of Technology, 2023. | |

| [26] | ZOU X J, LU J, LUO L F, et al. Extracting behavior knowledge and modeling based on virtual agricultural mobile robot[M]//PAN Z P, CHEOK A, HALLER M, et al. Advances in artificial reality and tele-existence. Berlin, Heidelberg: Springer, 2006: 28-37. |

| [27] | 兰海. 智慧农业对中国农业经济增长的影响研究[D]. 武汉: 武汉大学, 2022. |

| LAN H. The impact of smart agriculture on agricultural economic growth[D]. Wuhan: Wuhan University, 2022. | |

| [28] | 涂亮杰. 基于改进蚁群算法的果园移动机器人路径规划研究[D]. 衡阳: 南华大学, 2018. |

| TU L J. Research based on improved ant conlony alogorithm for mobible robot path planning[D]. Hengyang: University of South China, 2018. | |

| [29] | DIMEAS F, SAKO D V, MOULIANITIS V C, et al. Design and fuzzy control of a robotic gripper for efficient strawberry harvesting[J]. Robotica, 2015, 33(5): 1085-1098. |

| [30] | 史孝杰, 王树城, 刘惠敏, 等. 林果采摘机器人研究现状与展望[J]. 农业装备与车辆工程, 2024, 62(6): 1-7. |

| SHI X J, WANG S C, LIU H M, et al. Current status and prospects of research on forest fruit picking robots[J]. Agricultural Equipment & Vehicle Engineering, 2024, 62(6): 1-7. | |

| [31] | JIA W K, ZHANG Y, LIAN J, et al. Apple harvesting robot under information technology: a review[J]. International Journal of Advanced Robotic Systems, 2020, 17(3): 1729881420925310. |

| [32] | BAETEN J, DONNÉ K, BOEDRIJ S, et al. Autonomous fruit picking machine: a robotic apple harvester[M]// ALEXANDER Z. Field and service robotics. Berlin, Heidelberg: Springer, 2008: 531-539. |

| [33] | DE PRETER A, ANTHONIS J, DE BAERDEMAEKER J. Development of a robot for harvesting strawberries[J]. IFAC-PapersOnLine, 2018, 51(17): 14-19. |

| [34] | 李赞松. 油茶果采摘试验台的设计与研究[D]. 合肥: 安徽农业大学, 2017. |

| LI Z S. The design and research of Camellia oleifera picking test stand[D]. Hefei: Anhui Agricultural University, 2017. | |

| [35] | SARKAR P. Use of shaking mechanism and robotic arm in fruit harvesting: a comprehensive review[J]. Journal of Crop and Weed, 2021, 17(2): 1-9. |

| [36] | ZHANG Q, KARKEE M, TABB A, et al. The use of agricultural robots in orchard management[M]// BILLINGSLEY J. Robotics and automation for improving agriculture. London: Burleigh Dodds Science Publishing, 2019: 187-214. |

| [37] | 黄浩乾. 采摘机械手的设计及其控制研究[D]. 南京: 南京农业大学, 2010. |

| HUANG H Q. Research on design and control of harvesting manipulator[D]. Nanjing: Nanjing Agricultural University, 2010. | |

| [38] | LI Z Y, YUAN X J, WANG C Y. A review on structural development and recognition-localization methods for end-effector of fruit-vegetable picking robots[J]. International Journal of Advanced Robotic Systems, 2022, 19(3). |

| [39] | 崔鹏. 苹果采摘机器人末端执行器的设计研究[D]. 北京: 中国农业机械化科学研究院, 2010. |

| CUI P. Research and design of the end-effector of an apple-picking robot[D]. Beijing: Chinese Academy of Agricultural Mechanization Science, 2010. | |

| [40] | 孔德刚, 江达, 江东博, 等. 小型水果多功能采收装置设计与试验[J]. 中国农机化学报, 2023, 44(5): 19-25. |

| KONG D G, JIANG D, JIANG D B, et al. Design and test of multifunctional harvesting device for small fruits[J]. Journal of Chinese Agricultural Mechanization, 2023, 44(5): 19-25. | |

| [41] | 尚忠, 孙奎军, 钱栋伟, 等. 烟台市果园采摘环节机械化发展对策探析[J]. 山东农机化, 2018(5): 26-27. |

| SHANG Z, SUN K J, QIAN D W, et al. Countermeasures for mechanization development of orchard picking in Yantai City[J]. Shangdong Agricultural Mechanization, 2018(5): 26-27. | |

| [42] | NGUYEN T T, KAYACAN E, DE BAEDEMAEKER J, et al. Task and motion planning for apple harvesting robot[J]. IFAC Proceedings Volumes, 2013, 46(18): 247-252. |

| [43] | 陈青, 殷程凯, 郭自良, 等. 苹果采摘机器人关键技术研究现状与发展趋势[J]. 农业工程学报, 2023, 39(4): 1-15. |

| CHEN Q, YIN C K, GUO Z L, et al. Current status and future development of the key technologies for apple picking robots[J]. Transactions of the Chinese Society of Agricultural Engineering, 2023, 39(4): 1-15. | |

| [44] | 蓝峰, 苏子昊, 黎子明, 等. 果园采摘机械的现状及发展趋势[J]. 农机化研究, 2010, 32(11): 249-252. |

| LAN F, SU Z H, LI Z M, et al. The actuality and development directions of fruit harvesting machine[J]. Journal of Agricultural Mechanization Research, 2010, 32(11): 249-252. | |

| [45] | 何家成, 段文婷, 李凤佳, 等. 手持式电动水果采摘机设计[J]. 安徽农业科学, 2013, 41(25): 10557-10559. |

| HE J C, DUAN W T, LI F J, et al. The design of handheld electric fruit picking machine[J]. Journal of Anhui Agricultural Sciences, 2013, 41(25): 10557-10559. | |

| [46] | 王祺, 王艳玲, 俄胜哲. 我国果园机械装备现状及发展思路[J]. 农业机械, 2019(1): 109-111. |

| WANG Q, WANG Y L, E S Z. Current situation and development ideas of orchard machinery and equipment in China[J]. Farm machinery, 2019(1): 109-111. | |

| [47] | 刘西宁, 朱海涛, 巴合提. 牧神LG-1型多功能果园作业机的研制[J]. 新疆农机化, 2009(1): 42-44. |

| LIU X N, ZHU H T, BA H T. Development of LG-1 multifunctional orchard working machine[J]. Xinjiang Agricultural Mechanization, 2009(1): 42-44. | |

| [48] | 汤智辉, 沈从举, 孟祥金, 等. 4YS-24型红枣收获机的研制[J]. 新疆农机化, 2010(1): 30-32. |

| TANG Z H, SHEN C J, MENG X J, et al. Development of 4YS-24 jujube harvester[J]. Xinjiang Agricultural Mechanization, 2010(1): 30-32. | |

| [49] | 付荣利. 果园采摘机械的现状及发展趋势[J]. 农业开发与装备, 2011(5): 17-19. |

| FU R L. Present situation and development trend of orchard picking machinery[J]. Agricultural Development & Equipments, 2011(5): 17-19. | |

| [50] | 刘羊, 刘宇洋, 陈江春, 等. 标准化果园多功能作业平台关键技术研究现状与趋势[J]. 智能化农业装备学报(中英文), 2024(1): 31-39. |

| LIU Y, LIU Y Y, CHEN J C, et al. Research status and trend of key technologies of standardized orchard multi-functional operation platform[J]. Journal of Intelligent Agricultural Mechanization, 2024(1): 31-39. | |

| [51] | 仲崇迪. 苹果采摘机械臂避障系统设计及研究[D]. 秦皇岛: 燕山大学, 2020. |

| ZHONG C D. Design and research of obstacle-avoidance system for apple picking manipulator[D]. Qinhuangdao: Yanshan University, 2020. | |

| [52] | 杨文亮. 苹果采摘机器人机械手结构设计与分析[D]. 镇江: 江苏大学, 2009. |

| YANG W L. Design and analysis of apple harvesting robot’s manipulator[D]. Zhenjiang: Jiangsu University, 2009. | |

| [53] | 张玉. 近地面果蔬采摘机器人末端执行器及机械臂的研究[D]. 沈阳: 沈阳工业大学, 2014. |

| ZHANG Y. Research on the fruit-vegetable picking robot end executor and mechanical arm[D]. Shenyang: Shenyang University of Technology, 2014. | |

| [54] | 张凯良, 杨丽, 张铁中. 草莓采摘位置机器视觉与激光辅助定位方法[J]. 农业机械学报, 2010, 41(4): 151-156. |

| ZHANG K L, YANG L, ZHANG T Z. Object locating method of laser-assisted machine vision for strawberry-harvesting[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(4): 151-156. | |

| [55] | 王丽丽. 番茄采摘机器人关键技术研究[D]. 北京: 北京工业大学, 2017. |

| WANG L L. Research on key technology of tomato harvesting robot[D]. Beijing: Beijing University of Technology, 2017. | |

| [56] | 李国利. 多末端苹果采摘机器人设计与研究[D]. 南京: 南京农业大学, 2017. |

| LI G L. Design and research of apple picking robot with multiple end-effectors[D]. Nanjing: Nanjing Agricultural University, 2017. | |

| [57] | 刘鹏莉. 苹果采摘机器人的设计与研究[D]. 西安: 西安理工大学, 2018. |

| LIU P L. Research and design of an apple-picking robot[D]. Xi’an: Xi’an University of Technology, 2018. | |

| [58] | 何万贤, 方辉, 曾志康, 等. 特定自动采摘设备的机械臂位置控制算法的设计与实现[J]. 农业与技术, 2023, 43(15): 37-42. |

| HE W X, FANG H, ZENG Z K, et al. Design and implementation of manipulator position control algorithm for specific automatic picking equipment[J]. Agriculture and Technology, 2023, 43(15): 37-42. | |

| [59] | 李涛, 邱权, 赵春江, 等. 矮化密植果园多臂采摘机器人任务规划[J]. 农业工程学报, 2021, 37(2): 1-10. |

| LI T, QIU Q, ZHAO C J, et al. Task planning of multi-arm harvesting robots for high-density dwarf orchards[J]. Transactions of the Chinese Society of Agricultural Engineering, 2021, 37(2): 1-10. | |

| [60] | 于丰华, 周传琦, 杨鑫, 等. 日光温室番茄采摘机器人设计与试验[J]. 农业机械学报, 2022, 53(1): 41-49. |

| YU F H, ZHOU C Q, YANG X, et al. Design and experiment of tomato picking robot in solar greenhouse[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(1): 41-49. | |

| [61] | 董芒. 水果采摘机器人移动平台的设计与试验[D]. 南京: 南京农业大学, 2016. |

| DONG M. Design and experiment of fruit picking robot mobile platform[D]. Nanjing: Nanjing Agricultural University, 2016. | |

| [62] | 杜博. 苹果采摘机器人的机构设计及运动仿真[D]. 兰州: 兰州理工大学, 2022. |

| DU B. Mechanism design and motion simulation of apple picking robot[D]. Lanzhou: Lanzhou University of Technology, 2022. | |

| [63] | 宋加涛. 一种苹果采摘机器人的设计与研究[D]. 秦皇岛: 燕山大学, 2022. |

| SONG J T. Research and design of a apple picking robot[D]. Qinhuangdao: Yanshan University, 2022. | |

| [64] | 张永宏, 李宇超, 董天天, 等. 非结构化环境下番茄采摘机器人目标识别与检测[J]. 中国农机化学报, 2024, 45(4): 205-213. |

| ZHANG Y H, LI Y C, DONG T T, et al. Target identification and detection for tomato harvesting robot in unstructured environments[J]. Journal of Chinese Agricultural Mechanization, 2024, 45(4): 205-213. | |

| [65] | 赵春江, 范贝贝, 李瑾, 等. 农业机器人技术进展、挑战与趋势[J]. 智慧农业(中英文), 2023, 5(4): 1-15. |

| ZHAO C J, FAN B B, LI J, et al. Agricultural robots: technology progress, challenges and trends[J]. Smart Agriculture, 2023, 5(4): 1-15. |

| [1] | 刘婕, 疏再发, 刘林敏, 叶火香, 周慧娟, 吉庆勇, 何卫中. 茶叶全程机械化的研究与应用[J]. 浙江农业学报, 2025, 37(10): 2235-2246. |

| [2] | 王宁柯, 张瑞, 章胜勇. 机械化服务程度和农地经营规模对玉米生产效率的影响[J]. 浙江农业学报, 2023, 35(3): 698-707. |

| [3] | 魏政, 曹光乔. 城市化有利于农业机械化吗?——基于中国县域面板数据的实证分析[J]. 浙江农业学报, 2022, 34(12): 2778-2788. |

| [4] | 王克磊, 朱隆静, 苏世闻, 包玉花, 陈先知, 徐坚. 不同规格穴盘对番茄幼苗生长及其机械化移栽的影响[J]. 浙江农业学报, 2021, 33(5): 840-845. |

| [5] | 刘俊, 朱德泉, 于从羊, 薛康, 张顺, 廖娟. 舀勺型孔轮式水稻精量排种器设计与试验[J]. 浙江农业学报, 2021, 33(4): 739-752. |

| [6] | 沈升法;吴列洪;李兵. 春薯垄作方式研究[J]. , 2014, 26(3): 0-549555. |

| [7] | 居洪玲;姬长英*. 一种多用途采摘机器人末端执行器的设计[J]. , 2010, 22(3): 0-373. |

| [8] | 马广;周建忠. 基于灰色关联度的农机作业水平影响因素分析[J]. , 2007, 19(2): 0-100. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||