浙江农业学报 ›› 2026, Vol. 38 ›› Issue (1): 170-183.DOI: 10.3969/j.issn.1004-1524.20250126

油菜低损收获割台气力回收装置关键部件设计与试验

童学权1( ), 金裕国1, 宋熙1, 吴明亮1,2, 蒋啸虎1,2, 罗海峰1,2,*(

), 金裕国1, 宋熙1, 吴明亮1,2, 蒋啸虎1,2, 罗海峰1,2,*( )

)

- 1.湖南农业大学 机电工程学院,湖南 长沙 410128

2.湖南省现代农业装备工程技术研究中心,湖南 长沙 410128

-

收稿日期:2025-02-24出版日期:2026-01-25发布日期:2026-02-11 -

作者简介:罗海峰,E-mail:luohaifeng@hunau.edu.cn

童学权,研究方向为农业机械性能试验与创新设计。E-mail:tongxuequan2022@163.com -

通讯作者:罗海峰 -

基金资助:国家重点研发计划项目(2022YFD2300103);湖南省教育厅资助科研项目(22B0188);湖南省农业农村厅项目(湘财农指202045)

Design and experiment of key components for a pneumatic recovery system in the low-loss harvesting header of rapeseed

TONG Xuequan1( ), JIN Yuguo1, SONG Xi1, WU Mingliang1,2, JIANG Xiaohu1,2, LUO Haifeng1,2,*(

), JIN Yuguo1, SONG Xi1, WU Mingliang1,2, JIANG Xiaohu1,2, LUO Haifeng1,2,*( )

)

- 1. College of Engineering, Hunan Agricultural University, Changsha 410128, China

2. Hunan Key Laboratory of Intelligent Agricultural Machinery and Equipment, Changsha 410128, China

-

Received:2025-02-24Online:2026-01-25Published:2026-02-11 -

Contact:LUO Haifeng

摘要:

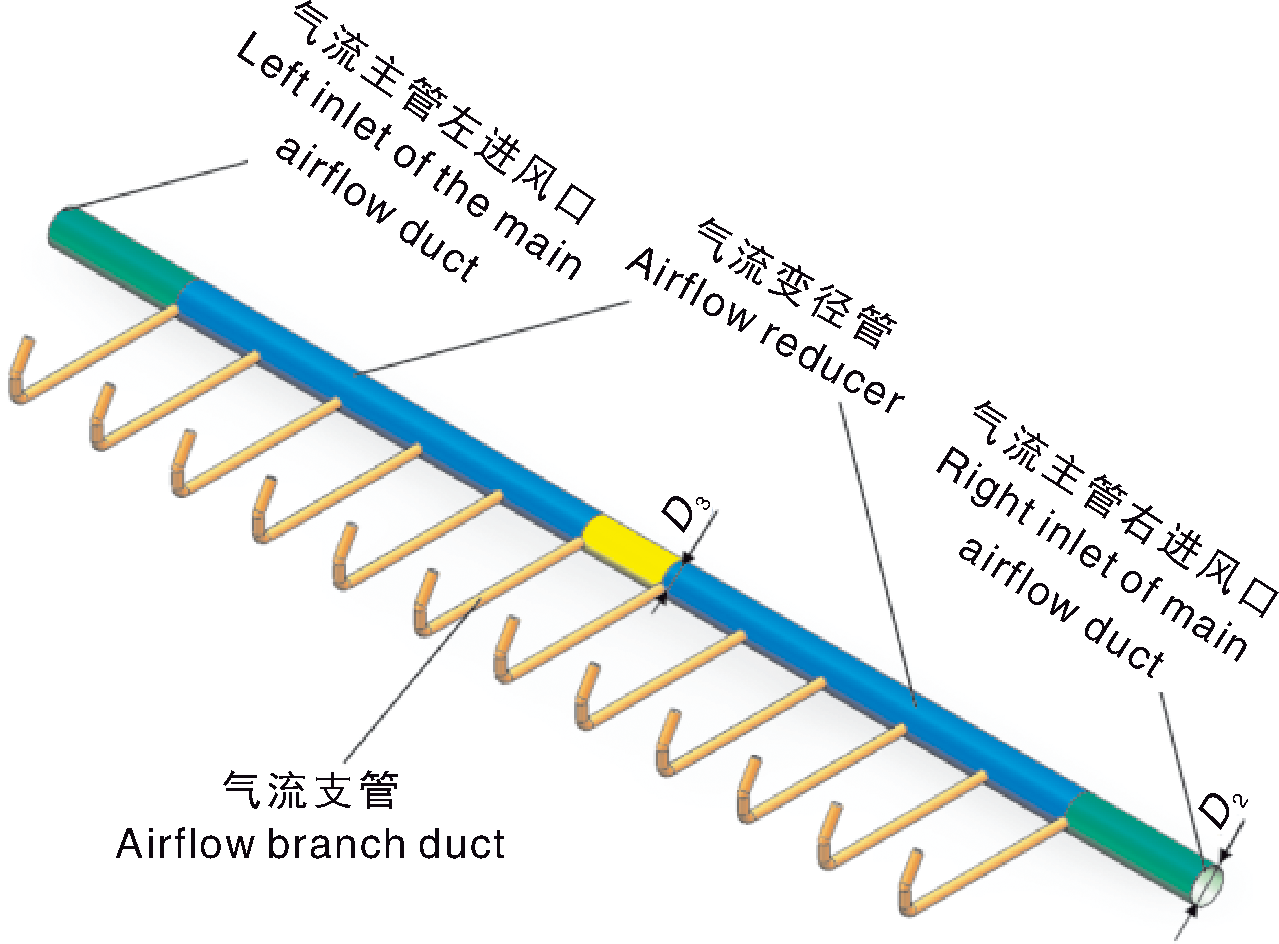

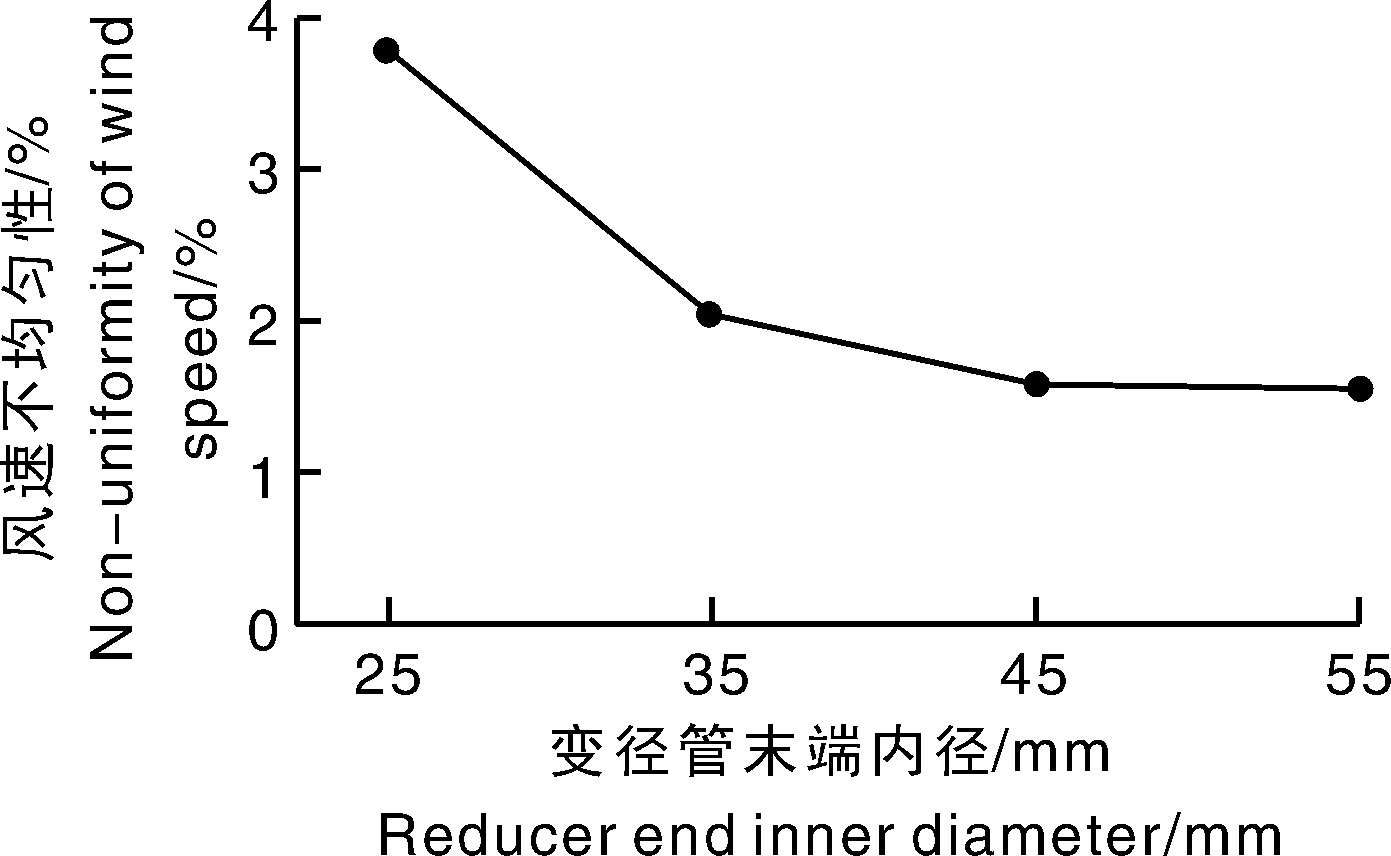

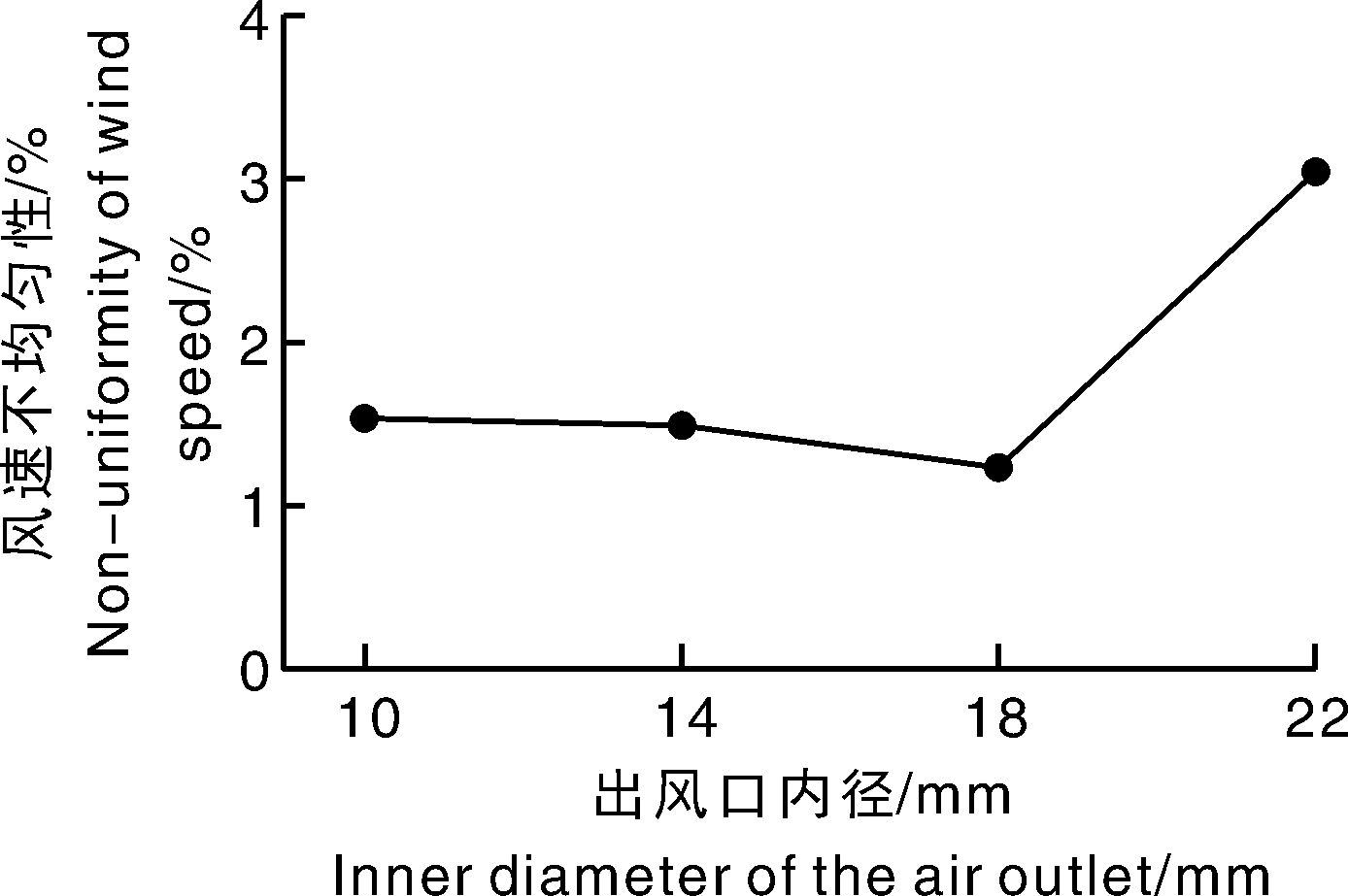

针对油菜联合收获过程中割台损失率高的问题,采用“双向进风-中间集中供气”方法设计了一种割台气力回收装置,该装置主要包括风机、传动系统、供气装置、割台和防溅挡板。通过供气装置产生的稳定风幕,以气吹方式实现炸荚掉落籽粒在割台上的定向回收,从而达到低损收获。基于Fluent对供气装置气流管道内部流场进行仿真优化,以气流主管左右进风口内径、气流变径管末端内径和气流支管出口内径为试验因素,以出口风速不均匀性为评价指标,开展三元二次回归正交组合仿真试验。结果表明,影响出口风速不均匀性的主次顺序依次为气流支管出口内径、气流变径管末端内径、气流主管左右进风口内径;管道最优参数组合为气流主管左右进风口内径63 mm、气流变径管末端内径56 mm、气流支管出口内径14 mm。以风机转速、水平距离和水平倾角为试验因素,以籽粒回收率为评价指标,开展台架试验;结果表明,当风机转速3 000 r·min-1、水平距离350.5 mm、水平倾角76.8°时籽粒回收效果最佳。在现有油菜联合收获机上,利用脱粒动力加装一套机械传动系统驱动气力回收装置,试制了油菜气吹式割台低损联合收获机。该气力回收装置出口风速不均匀性为1.19%,气流稳定性良好;田间试验结果表明,割台损失率为2.75%,较未启用气力回收功能时割台损失率降低1.3百分点,实现了低损联合收获作业。

中图分类号:

引用本文

童学权, 金裕国, 宋熙, 吴明亮, 蒋啸虎, 罗海峰. 油菜低损收获割台气力回收装置关键部件设计与试验[J]. 浙江农业学报, 2026, 38(1): 170-183.

TONG Xuequan, JIN Yuguo, SONG Xi, WU Mingliang, JIANG Xiaohu, LUO Haifeng. Design and experiment of key components for a pneumatic recovery system in the low-loss harvesting header of rapeseed[J]. Acta Agriculturae Zhejiangensis, 2026, 38(1): 170-183.

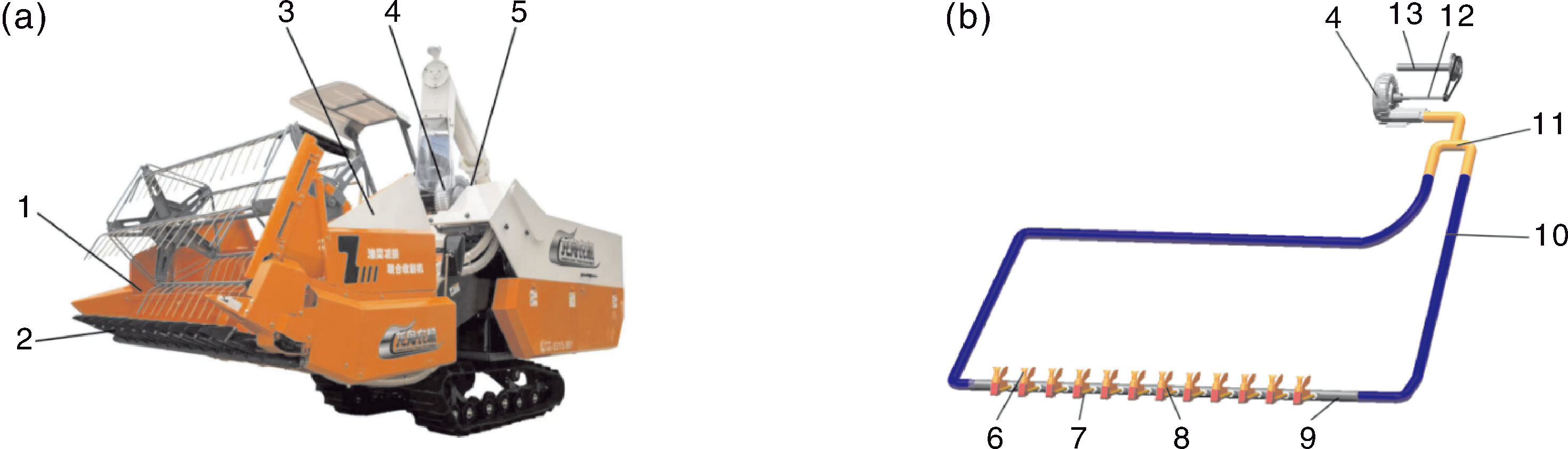

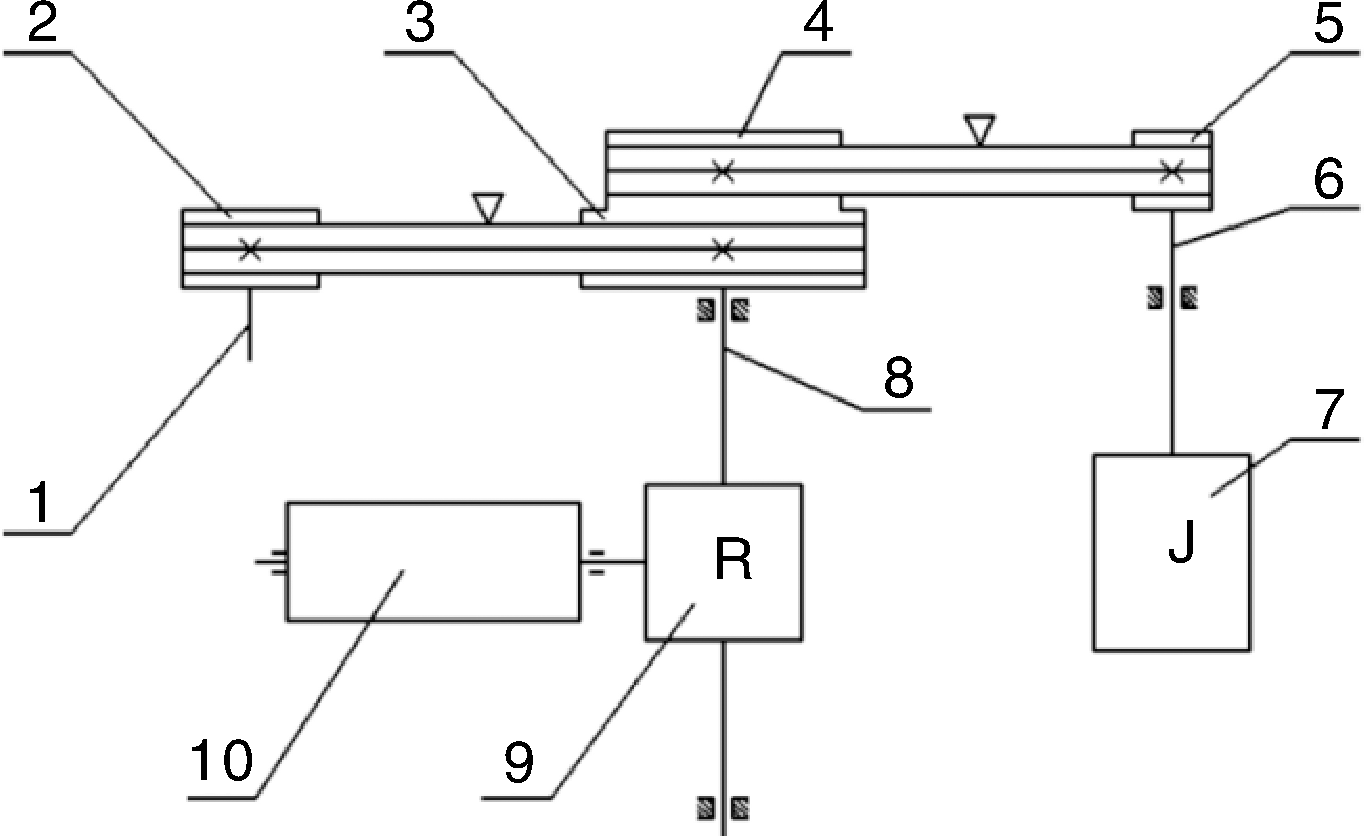

图1 割台气力回收装置结构示意图 a,低损失油菜联合收获机气吹式割台样机;b,割台低损失回收气流单元示意图。1,割台;2,供气装置;3,防溅挡板;4,风机;5,传动系统;6,鸭嘴喷头;7,气流支管;8,连接片;9,气流主管;10,气流软管;11,气流分流器;12,风机转轴;13,脱粒输入轴。

Fig.1 Structural schematic diagram of the header pneumatic recovery device a, Prototype of low-loss rapeseed combining harvester with air-blown header; b, Schematic diagram of low loss recovery air supply unit for cutting table. 1, Cutting table; 2, Air supply unit; 3, Splash guard; 4, Blower; 5, Transmission system; 6, Duckbill nozzle; 7, Airflow branch duct; 8, Connection piece; 9, Airflow main duct; 10, Airflow hose; 11, Airflow diverter; 12, Blower rotor shaft; 13, Threshing input shaft.

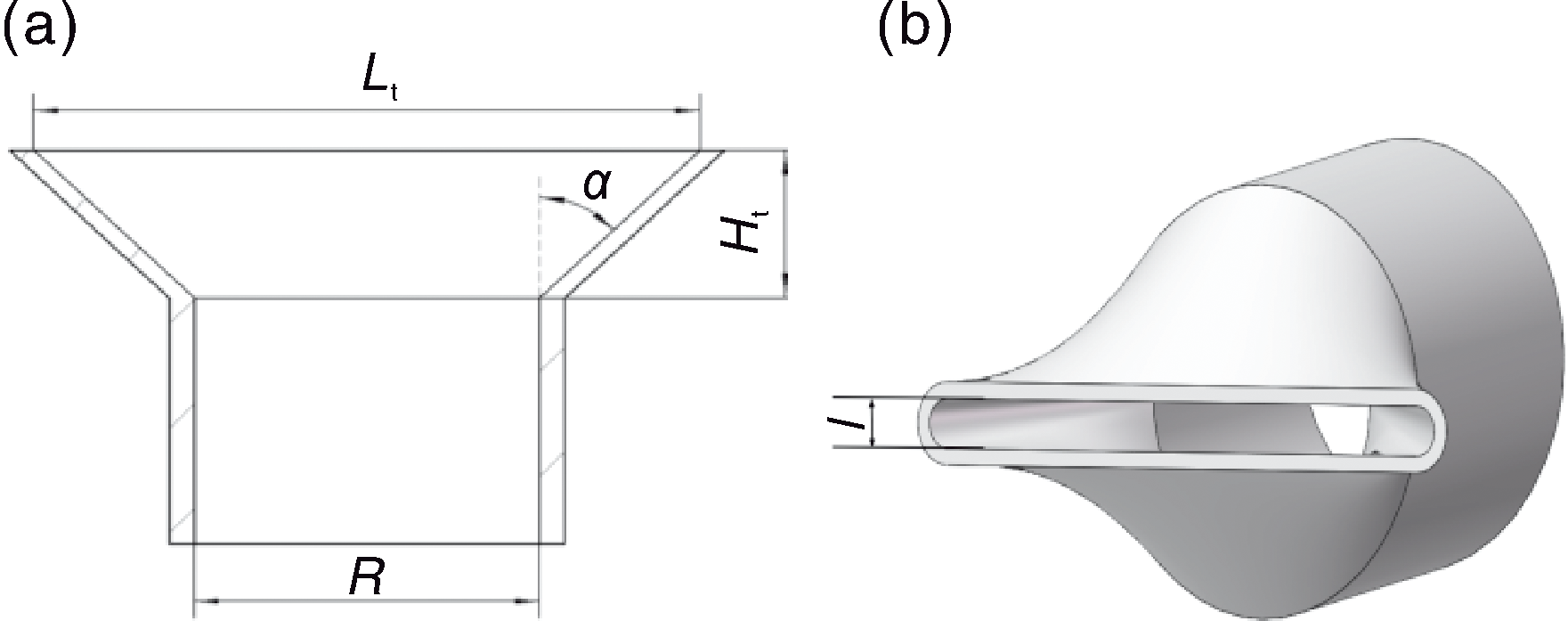

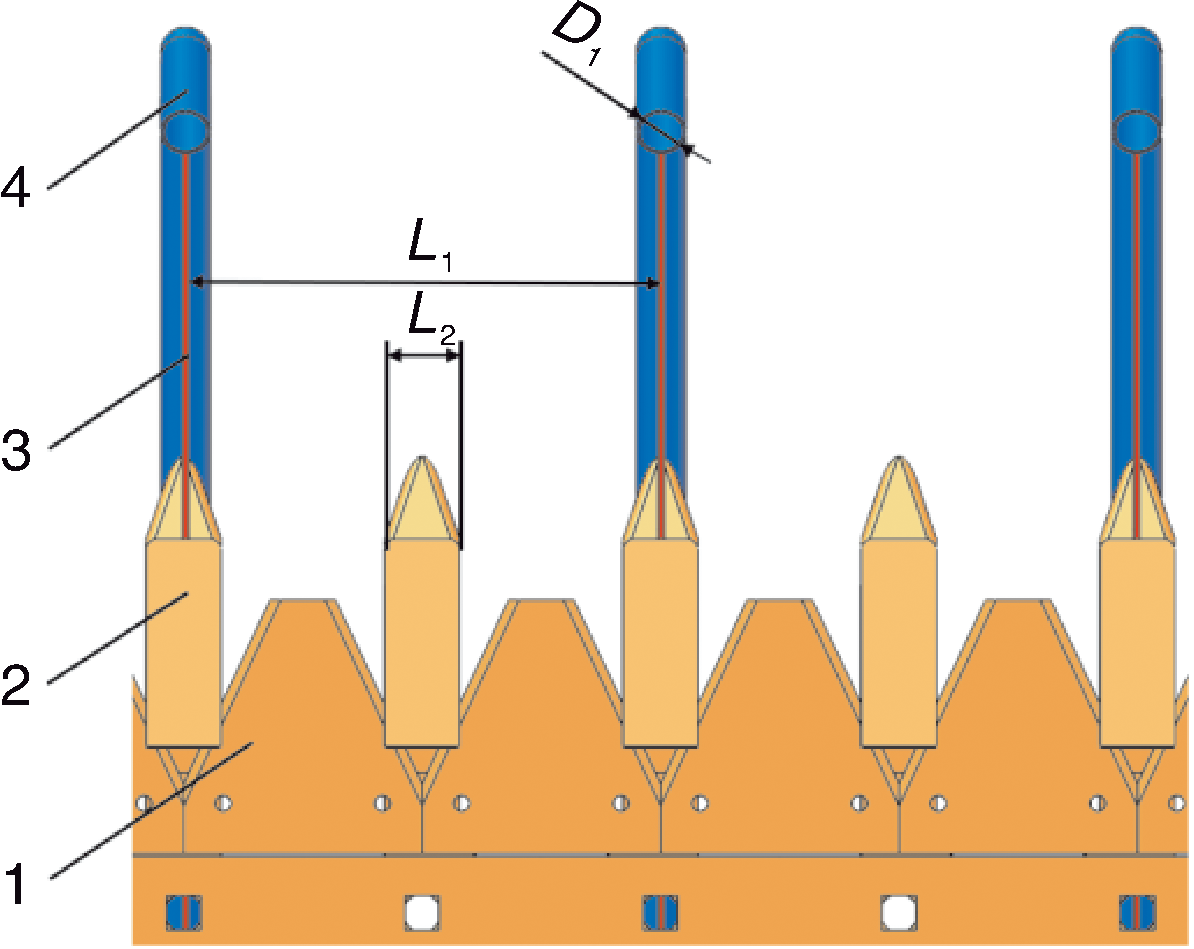

图2 护刃器与气流支管一体化示意图 1,割刀;2,护刃器;3,连接片;4,气流支管。D1,气流支管内径;L1,割刀护刃器间距;L2,护刃器两端垂直距离。

Fig.2 Schematic diagram of the integration of the blade guard and the airflow branch duct 1, Cutter; 2, Blade guard; 3, Connecting piece; 4, Airflow branch duct. D1, Inner diameter of the airflow branch duct; L1, Spacing between the cutter guards; L2, Vertical distance between the two ends of the cutter guard.

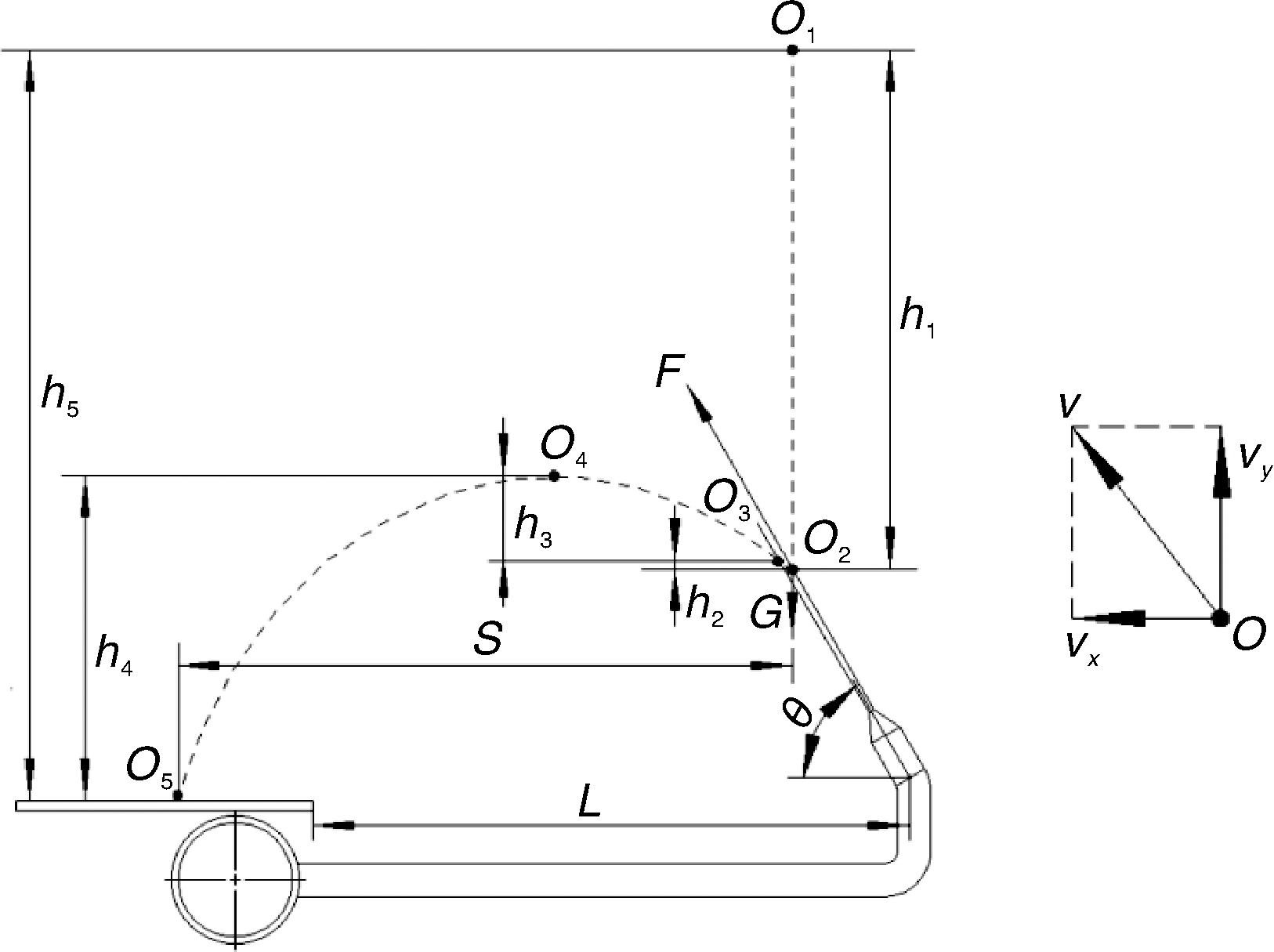

图3 籽粒运动分析图 L,气流支管出口距割刀水平距离(简称水平距离);θ,出口与水平方向倾角(简称水平倾角);vx,籽粒在O点的水平速度;vy,籽粒在O点的竖直速度。

Fig.3 Diagram of grain motion L, Horizontal distance between the outlet of branch airflow duct and the installation point of the horizontal cutter (abbreviated as horizontal distance); θ, Angle of inclination between the outlet and the horizontal direction (abbreviated as horizontal inclination angle); vx, Horizontal velocity of the grain at point O; vy, Vertical velocity of the grain at point O.

| 参数 Parameters | 结构形态 Configuration | 进风口风速/(m·s-1) Wind speed of inlet/(m·s-1) | 气流主管内径/mm Inner diameter of the main airflow duct/mm | 气流支管内径/mm Inner diameter of the branch airflow duct/mm |

|---|---|---|---|---|

| 模型A Model A | 单侧进风Single-side air intake | 60 | 60 | 18 |

| 模型B Model B | 双侧进风Double-side air intake | 30 | 60 | 18 |

| 模型C Model C | 双中通进风Dual-central air intake | 30 | 60 | 18 |

表1 3种气流管道模型参数

Table 1 Parameters of the three airflow duct models

| 参数 Parameters | 结构形态 Configuration | 进风口风速/(m·s-1) Wind speed of inlet/(m·s-1) | 气流主管内径/mm Inner diameter of the main airflow duct/mm | 气流支管内径/mm Inner diameter of the branch airflow duct/mm |

|---|---|---|---|---|

| 模型A Model A | 单侧进风Single-side air intake | 60 | 60 | 18 |

| 模型B Model B | 双侧进风Double-side air intake | 30 | 60 | 18 |

| 模型C Model C | 双中通进风Dual-central air intake | 30 | 60 | 18 |

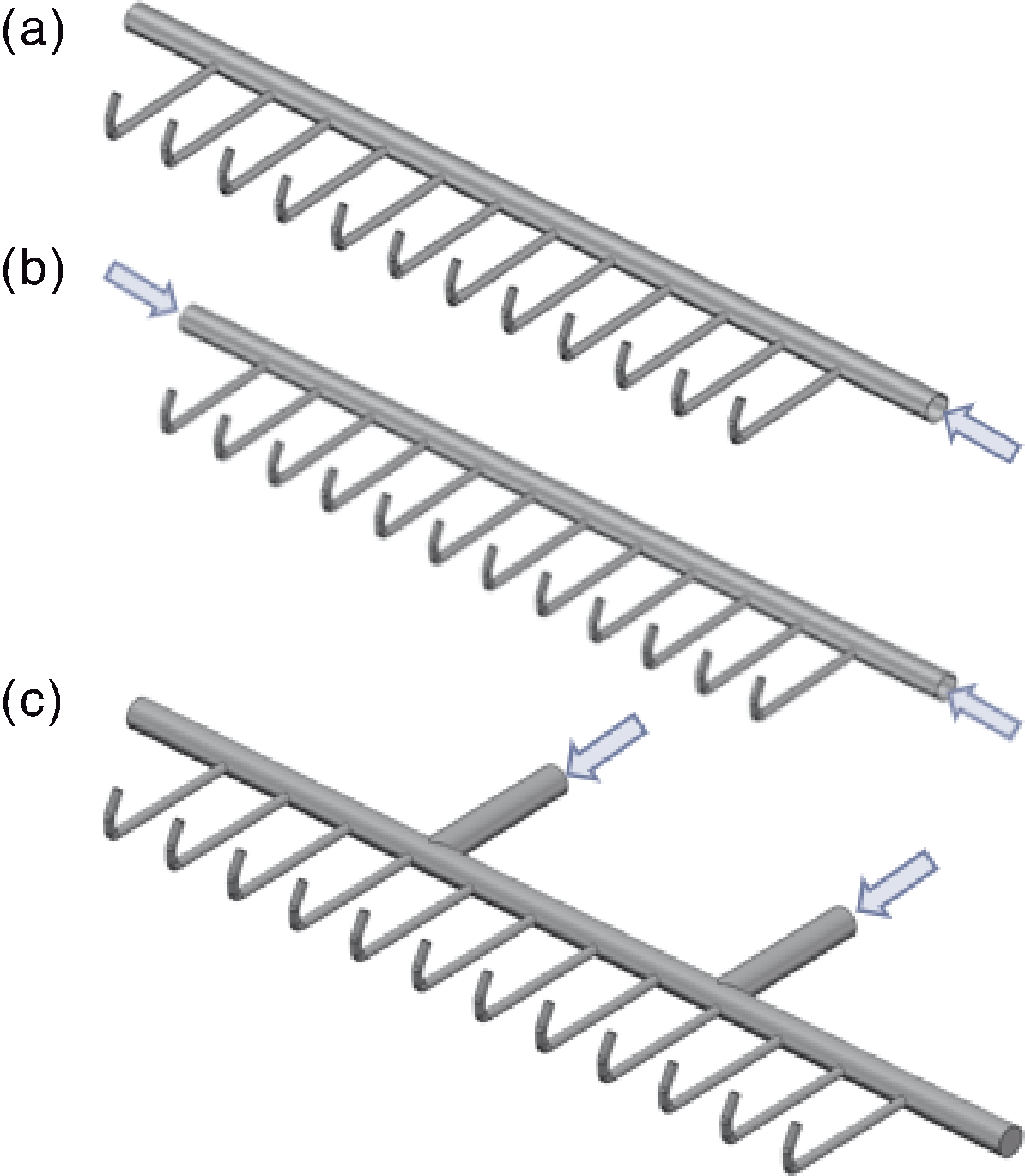

图4 管道模型进风示意图 a,单侧进风管道模型;b,双侧进风管道模型;c,双中通进风管道模型。

Fig.4 Schematic diagram of air intake in the duct model a, Modeling of single-side air intake; b, Modeling of double-side air intake; c, Dual-central air intake.

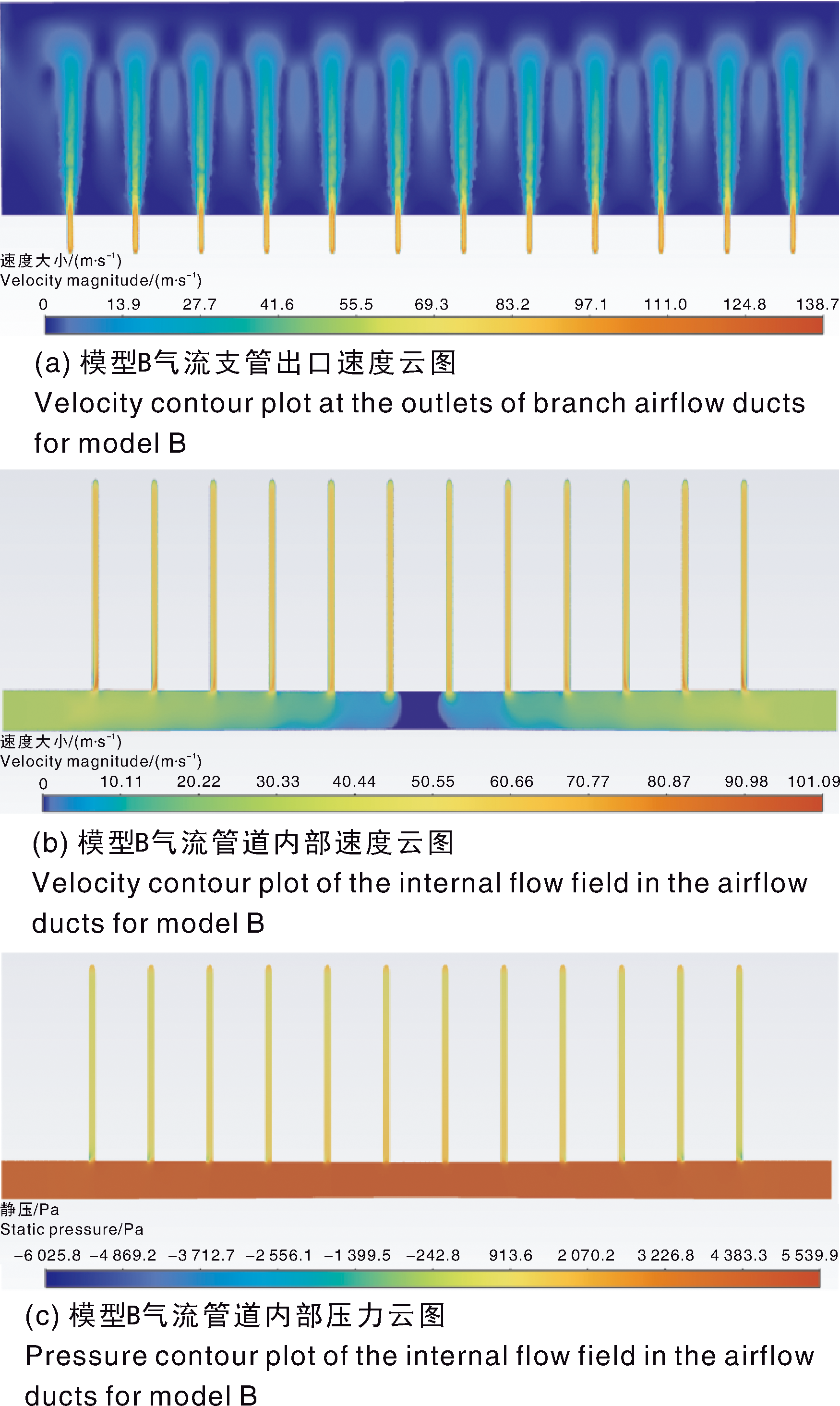

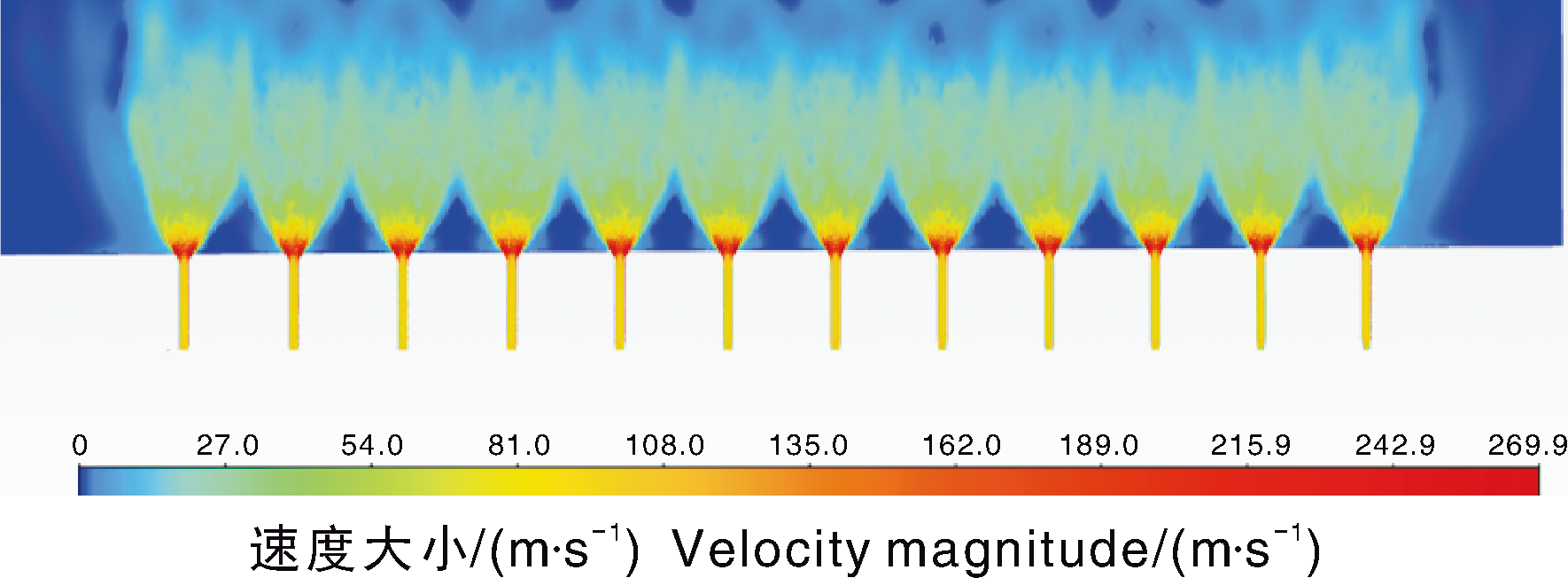

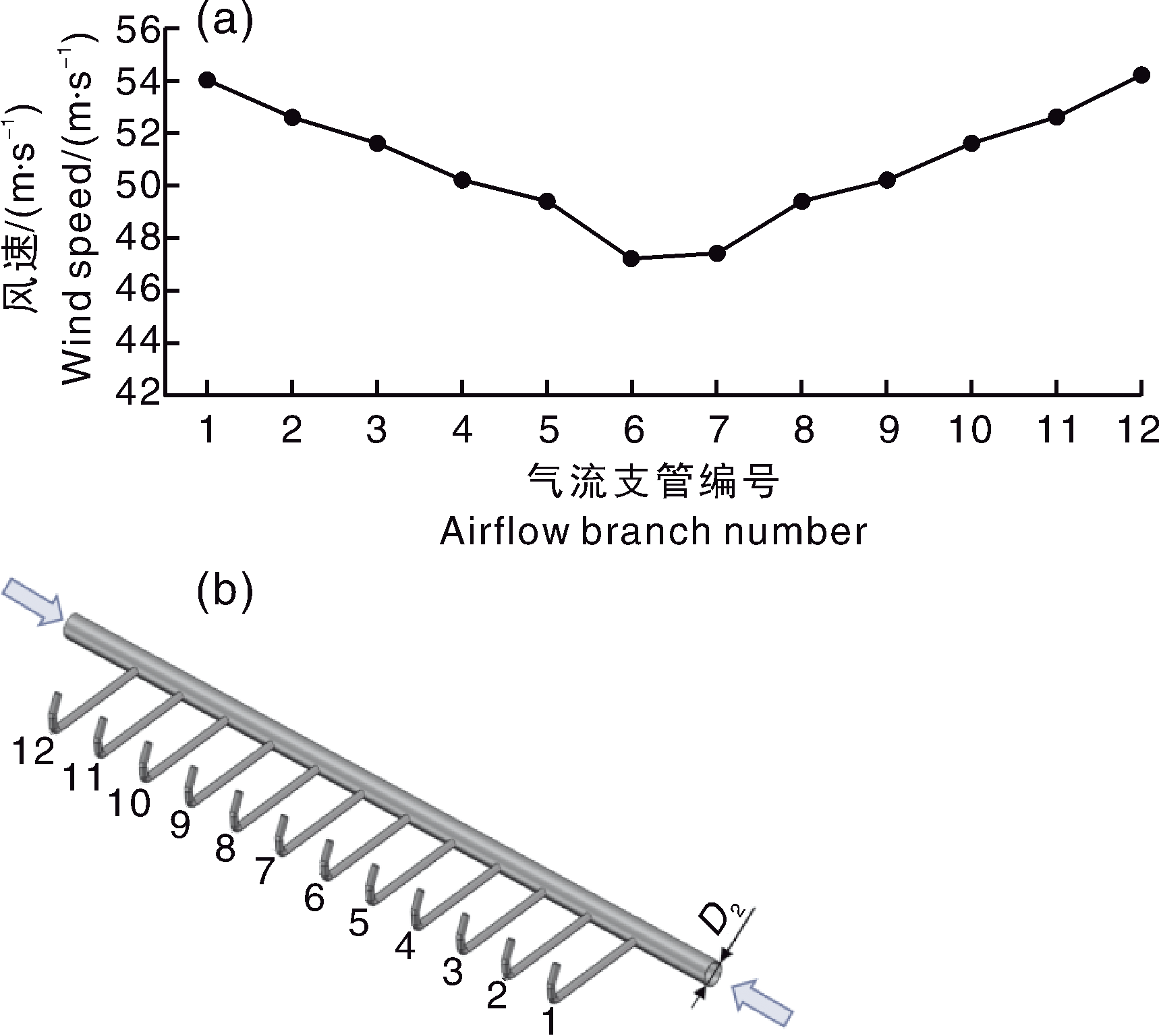

图6 模型B各支管出口风速变化示意图 a,模型B各支管出口风速;b,模型B各支管编号。D2,主管内径。下同。

Fig.6 Schematic diagram of wind speed variation at the outlet of each branch duct in model B a, Wind speed at the outlet of branch ducts for model B; B, Each branch duct number of Model B. D2, Inner diameter of main duct.The same as below.

| 编码 Code | 因素Factors | ||

|---|---|---|---|

| A | B | C | |

| -1 | 50 | 50 | 14 |

| 0 | 60 | 55 | 18 |

| 1 | 70 | 60 | 22 |

表2 交互试验因素编码

Table 2 Factor code of factorial experiments mm

| 编码 Code | 因素Factors | ||

|---|---|---|---|

| A | B | C | |

| -1 | 50 | 50 | 14 |

| 0 | 60 | 55 | 18 |

| 1 | 70 | 60 | 22 |

| 试验组 Test group | A/mm | B/mm | C/mm | W/% |

|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 2.24 |

| 2 | 1 | -1 | 0 | 1.46 |

| 3 | -1 | 1 | 0 | 2.01 |

| 4 | 1 | 1 | 0 | 2.76 |

| 5 | -1 | 0 | -1 | 1.35 |

| 6 | -1 | 0 | -1 | 1.02 |

| 7 | -1 | 0 | 1 | 3.46 |

| 8 | 1 | 0 | 1 | 3.04 |

| 9 | 0 | -1 | -1 | 1.03 |

| 10 | 0 | 1 | -1 | 1.49 |

| 11 | 0 | -1 | 1 | 3.19 |

| 12 | 0 | 1 | 1 | 3.16 |

| 13 | 0 | 0 | 0 | 1.18 |

| 14 | 0 | 0 | 0 | 1.18 |

表3 试验方案与结果

Table 3 Test protocol and results

| 试验组 Test group | A/mm | B/mm | C/mm | W/% |

|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 2.24 |

| 2 | 1 | -1 | 0 | 1.46 |

| 3 | -1 | 1 | 0 | 2.01 |

| 4 | 1 | 1 | 0 | 2.76 |

| 5 | -1 | 0 | -1 | 1.35 |

| 6 | -1 | 0 | -1 | 1.02 |

| 7 | -1 | 0 | 1 | 3.46 |

| 8 | 1 | 0 | 1 | 3.04 |

| 9 | 0 | -1 | -1 | 1.03 |

| 10 | 0 | 1 | -1 | 1.49 |

| 11 | 0 | -1 | 1 | 3.19 |

| 12 | 0 | 1 | 1 | 3.16 |

| 13 | 0 | 0 | 0 | 1.18 |

| 14 | 0 | 0 | 0 | 1.18 |

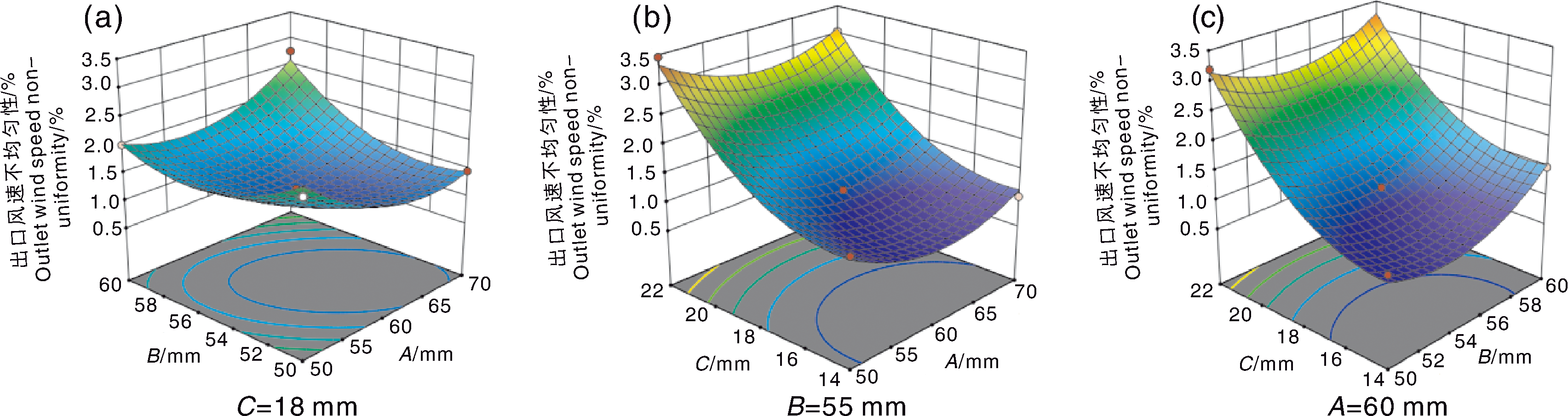

图10 交互因素对出口风速不均匀性影响的响应曲面 A,左右进风口内径;B,变径管末端内径;C,支管出口内径。

Fig.10 Response surface of interaction effects on wind speed non-uniformity at outlet A, Inner diameter of left and right air inlet; B, Inner diameter at the end of the reducer; C, Inner diameter of the branch duct outlet.

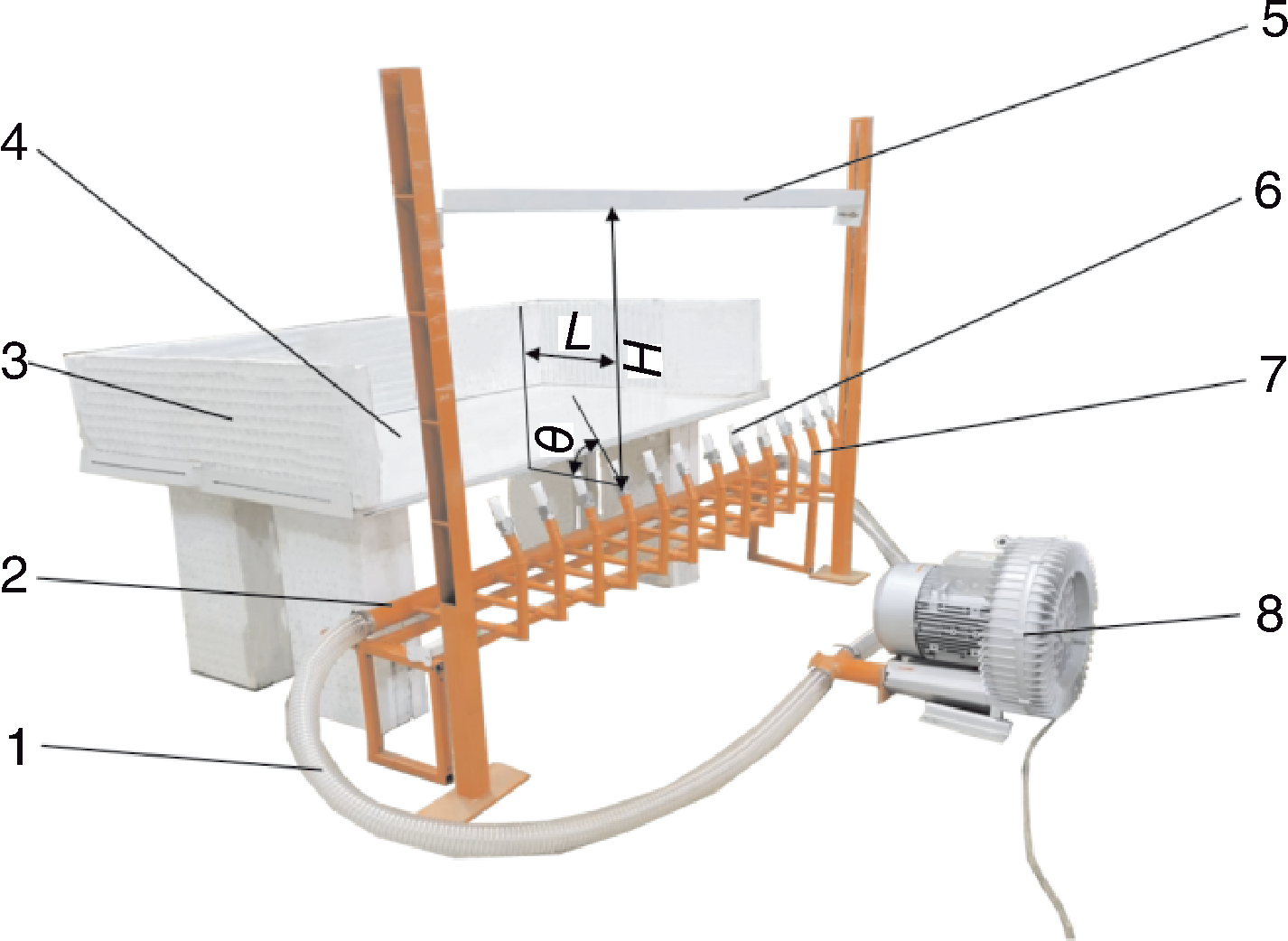

图13 台架试验 1,气流软管;2,气流主管;3,防溅挡板;4,收集平台;5,长槽;6,鸭嘴喷头;7,气流支管;8,风机。H为长槽与收集平台之间的垂直距离。

Fig.13 Bench test 1, Airflow hose; 2, Airflow main duct; 3, Splash guard; 4, Collection platform; 5, Long slot; 6, Duckbill nozzle; 7, Airflow branch duct; 8, Fan. H, Vertical distance from long slot to collection platform.

| 编码 Code | 因素Factors | ||

|---|---|---|---|

| f/Hz | L/mm | θ/(°) | |

| -1 | 30 | 300 | 60 |

| 0 | 40 | 350 | 70 |

| 1 | 50 | 400 | 80 |

表4 台架试验因素编码

Table 4 Factor code of bench test

| 编码 Code | 因素Factors | ||

|---|---|---|---|

| f/Hz | L/mm | θ/(°) | |

| -1 | 30 | 300 | 60 |

| 0 | 40 | 350 | 70 |

| 1 | 50 | 400 | 80 |

| 试验组 Test group | f/Hz | L/mm | θ/(°) | ω/% |

|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 13.2 |

| 2 | 1 | -1 | 0 | 64.6 |

| 3 | -1 | 1 | 0 | 12.8 |

| 4 | 1 | 1 | 0 | 64.8 |

| 5 | -1 | 0 | -1 | 14.4 |

| 6 | 1 | 0 | -1 | 58.7 |

| 7 | -1 | 0 | 1 | 13.8 |

| 8 | 1 | 0 | 1 | 65.4 |

| 9 | 0 | -1 | -1 | 38.6 |

| 10 | 0 | 1 | -1 | 41.3 |

| 11 | 0 | -1 | 1 | 42.2 |

| 12 | 0 | -1 | 1 | 42.3 |

| 13 | 0 | 0 | 0 | 44.1 |

| 14 | 0 | 0 | 0 | 45.7 |

| 15 | 0 | 0 | 0 | 44.4 |

| 16 | 0 | 0 | 0 | 44.9 |

| 17 | 0 | 0 | 0 | 45.8 |

表5 试验设计方案与结果

Table 5 Experimental design and results

| 试验组 Test group | f/Hz | L/mm | θ/(°) | ω/% |

|---|---|---|---|---|

| 1 | -1 | -1 | 0 | 13.2 |

| 2 | 1 | -1 | 0 | 64.6 |

| 3 | -1 | 1 | 0 | 12.8 |

| 4 | 1 | 1 | 0 | 64.8 |

| 5 | -1 | 0 | -1 | 14.4 |

| 6 | 1 | 0 | -1 | 58.7 |

| 7 | -1 | 0 | 1 | 13.8 |

| 8 | 1 | 0 | 1 | 65.4 |

| 9 | 0 | -1 | -1 | 38.6 |

| 10 | 0 | 1 | -1 | 41.3 |

| 11 | 0 | -1 | 1 | 42.2 |

| 12 | 0 | -1 | 1 | 42.3 |

| 13 | 0 | 0 | 0 | 44.1 |

| 14 | 0 | 0 | 0 | 45.7 |

| 15 | 0 | 0 | 0 | 44.4 |

| 16 | 0 | 0 | 0 | 44.9 |

| 17 | 0 | 0 | 0 | 45.8 |

| 方差来源 Source of variance | 平方和 Square sum | 自由度 Degree of freedom | 均方 Mean square | F | p |

|---|---|---|---|---|---|

| 模型Model | 5 127.27 | 9 | 569.70 | 371.12 | <0.000 1 |

| f | 4 965.06 | 1 | 4 965.06 | 3 234.42 | <0.000 1 |

| L | 0.845 0 | 1 | 0.845 0 | 0.550 5 | 0.442 3 |

| θ | 14.31 | 1 | 14.31 | 9.32 | 0.018 5 |

| fL | 0.090 0 | 1 | 0.090 0 | 0.058 6 | 0.815 6 |

| fθ | 13.32 | 1 | 13.32 | 8.68 | 0.021 5 |

| Lθ | 1.69 | 1 | 1.69 | 1.10 | 0.326 9 |

| f2 | 88.23 | 1 | 88.23 | 57.47 | 0.000 1 |

| L2 | 10.15 | 1 | 10.15 | 6.61 | 0.036 9 |

| θ2 | 22.81 | 1 | 22.81 | 14.86 | 0.006 3 |

| 残差Residual | 10.75 | 7 | 1.54 | ||

| 失拟项Lack of fit | 8.44 | 3 | 2.81 | 4.87 | 0.080 0 |

| 总和Total | 5 138.02 | 16 |

表6 回归方程方差分析

Table 6 Analysis of variance for the regression equation

| 方差来源 Source of variance | 平方和 Square sum | 自由度 Degree of freedom | 均方 Mean square | F | p |

|---|---|---|---|---|---|

| 模型Model | 5 127.27 | 9 | 569.70 | 371.12 | <0.000 1 |

| f | 4 965.06 | 1 | 4 965.06 | 3 234.42 | <0.000 1 |

| L | 0.845 0 | 1 | 0.845 0 | 0.550 5 | 0.442 3 |

| θ | 14.31 | 1 | 14.31 | 9.32 | 0.018 5 |

| fL | 0.090 0 | 1 | 0.090 0 | 0.058 6 | 0.815 6 |

| fθ | 13.32 | 1 | 13.32 | 8.68 | 0.021 5 |

| Lθ | 1.69 | 1 | 1.69 | 1.10 | 0.326 9 |

| f2 | 88.23 | 1 | 88.23 | 57.47 | 0.000 1 |

| L2 | 10.15 | 1 | 10.15 | 6.61 | 0.036 9 |

| θ2 | 22.81 | 1 | 22.81 | 14.86 | 0.006 3 |

| 残差Residual | 10.75 | 7 | 1.54 | ||

| 失拟项Lack of fit | 8.44 | 3 | 2.81 | 4.87 | 0.080 0 |

| 总和Total | 5 138.02 | 16 |

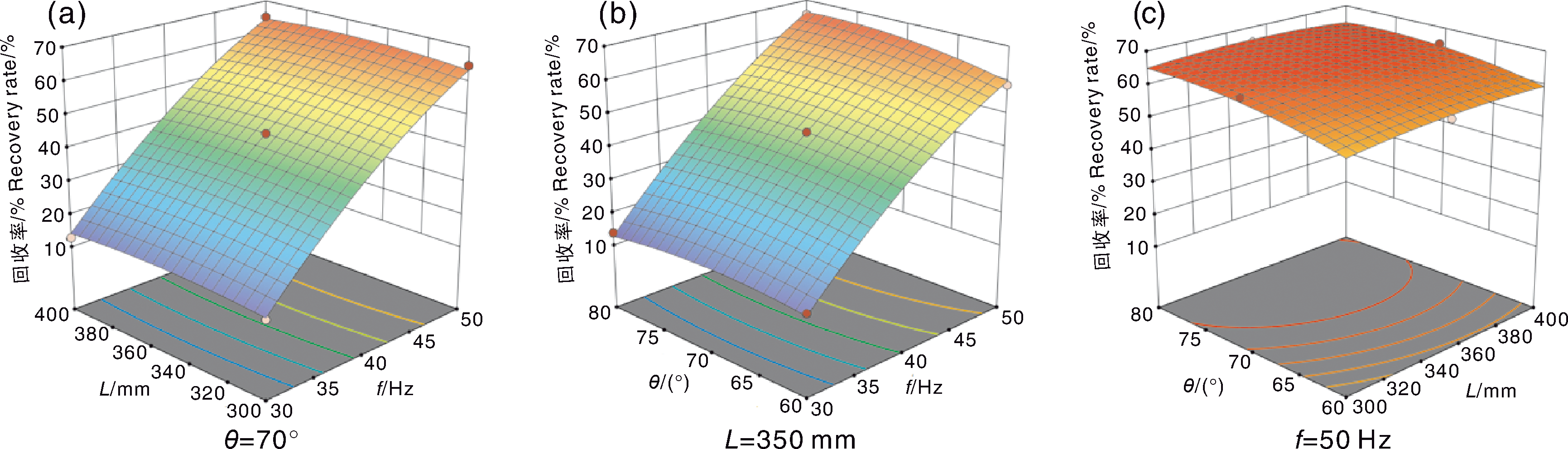

图14 交互因素对回收率影响的响应曲面 f,风机工作频率;L,水平距离;θ,水平倾角。

Fig.14 Response surface of the effect of interaction factors on the recovery rate f, Frequency; L, Horizontal distance; θ, Horizontal inclination.

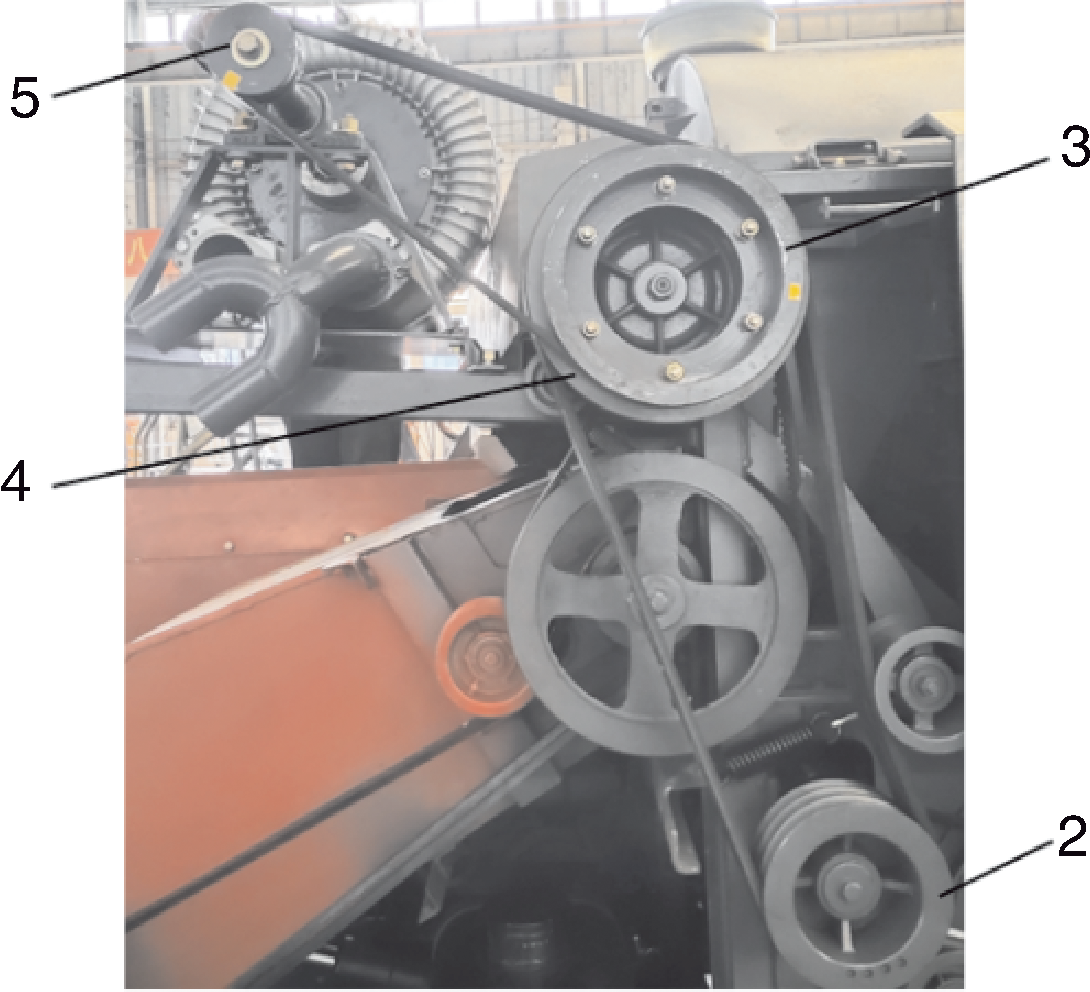

图16 风机传动系统简图 1,收获机贯流风机轴;2,贯流风机皮带轮;3,脱粒复式皮带轮(Ⅰ);4,脱粒复式皮带轮(Ⅱ);5,风机皮带轮;6,风机轴;7,风机;8,脱粒输入轴;9,换向装置;10,脱粒滚筒。

Fig.16 Schematic diagram of fan drive system 1, Harvester cross-flow fan shaft; 2, Cross-flow fan pulley; 3, Threshing compound pulley (Ⅰ); 4, Threshing compound pulley (Ⅱ); 5, Fan pulley; 6, Fan shaft; 7, Fan; 8, Threshing input shaft; 9, Commutator; 10, Threshing roller.

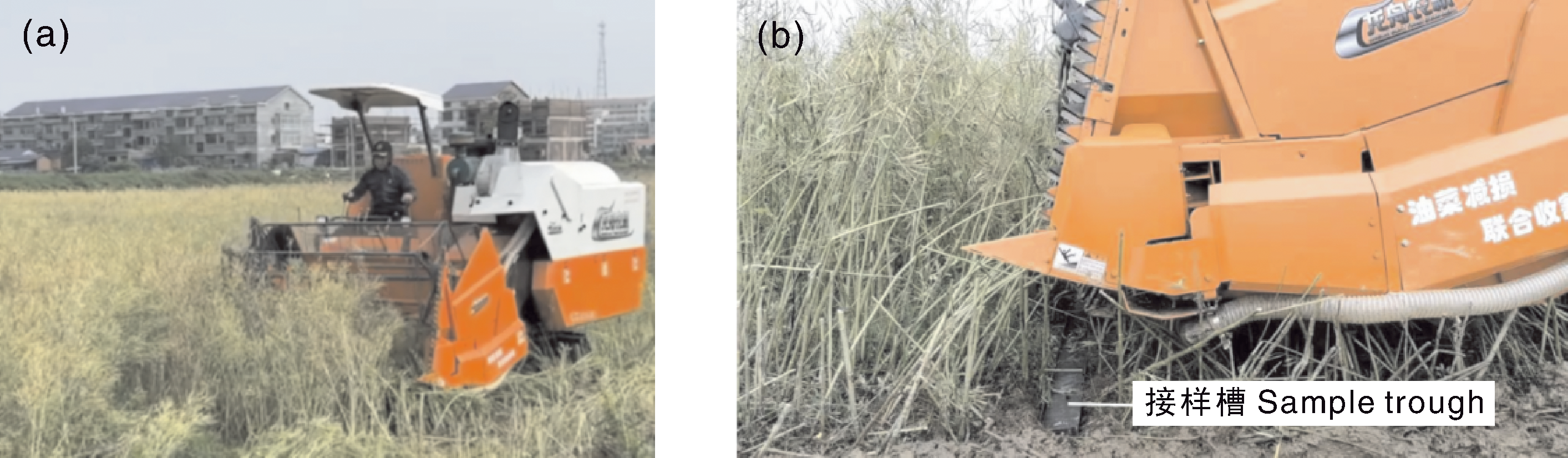

| 试验序号 Test number | 前进速度/(m·s-1) Forward speed/(m·s-1) | 接样槽回收总质量/g Total mass collected in sample trough/g | 割台损失质量/(g·m-2) Header loss mass/(g·m-2) | 割台损失率/% Header loss rate/% |

|---|---|---|---|---|

| 1 | 1.12 | 2.88 | 4.80 | 2.41 |

| 2 | 1.04 | 3.72 | 6.20 | 3.11 |

| 3 | 1.08 | 3.27 | 5.45 | 2.73 |

| 平均值Average value | 1.08 | 3.29 | 5.48 | 2.75 |

表7 田间试验结果

Table 7 Results of field experiments

| 试验序号 Test number | 前进速度/(m·s-1) Forward speed/(m·s-1) | 接样槽回收总质量/g Total mass collected in sample trough/g | 割台损失质量/(g·m-2) Header loss mass/(g·m-2) | 割台损失率/% Header loss rate/% |

|---|---|---|---|---|

| 1 | 1.12 | 2.88 | 4.80 | 2.41 |

| 2 | 1.04 | 3.72 | 6.20 | 3.11 |

| 3 | 1.08 | 3.27 | 5.45 | 2.73 |

| 平均值Average value | 1.08 | 3.29 | 5.48 | 2.75 |

| [1] | 张哲, 殷艳, 刘芳, 等. 我国油菜多功能开发利用现状及发展对策[J]. 中国油料作物学报, 2018, 40(5): 618-623. |

| ZHANG Z, YIN Y, LIU F, et al. Current situation and development countermeasures of Chinese rapeseed multifunctional development and utilization[J]. Chinese Journal of Oil Crop Sciences, 2018, 40(5): 618-623. | |

| [2] | 胡志勇, 鲜孟筑, 李俊. 我国油菜品种改良现状及发展趋势[J]. 中国农业大学学报, 2024, 29(3): 50-62. |

| HU Z Y, XIAN M Z, LI J. Current situation and development trends of rapeseed variety improvement in China[J]. Journal of China Agricultural University, 2024, 29(3): 50-62. | |

| [3] | 郑娟, 黄凰, 廖宜涛, 等. 长江中游地区油菜生产全程机械化技术进展与建议[J]. 中国油料作物学报, 2024, 46(2): 245-259. |

| ZHENG J, HUANG H, LIAO Y T, et al. Progress and suggestions on full mechanization of rapeseed production in the middle reaches of the Yangtze River[J]. Chinese Journal of Oil Crop Sciences, 2024, 46(2): 245-259. | |

| [4] | 李勤, 刘小焱, 盛紫微, 等. 我国油菜适合机械化收获关键农艺性状研究进展[J]. 中国油料作物学报, 2023, 45(5): 1053-1061. |

| LI Q, LIU X Y, SHENG Z W, et al. Research progress on target agronomic traits for mechanized harvesting of rapeseed in China[J]. Chinese Journal of Oil Crop Sciences, 2023, 45(5): 1053-1061. | |

| [5] | 马丽娜, 魏俊逸, 黄小毛, 等. 油菜联合收获机割台振动对田间收获落粒影响分析[J]. 农业机械学报, 2020, 51(S2): 134-138. |

| MA L N, WEI J Y, HUANG X M, et al. Analysis of the effect of oilseed rape combine harvester cutting table vibration on field harvesting grain drop[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(S2): 134-138. | |

| [6] | 冉军辉, 沐森林, 李海同, 等. 油菜联合收获机往复式双动割刀行星轮驱动器设计与试验[J]. 农业工程学报, 2020, 36(9): 17-25. |

| RAN J H, MU S L, LI H T, et al. Design and test of planet gear driver of reciprocating double-acting cutter for rapeseed combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(9): 17-25. | |

| [7] | 周玉姣, 罗斌, 刘定炜, 等. 4LZ-4.0谷物联合收获机油菜割台设计与试验[J]. 中国农机化学报, 2023, 44(9): 22-27. |

| ZHOU Y J, LUO B, LIU D W, et al. Design and experiment of rape cutter in 4LZ-4.0 grain combine harvester[J]. Journal of Chinese Agricultural Mechanization, 2023, 44(9): 22-27. | |

| [8] | 李海同, 万星宇, 王华, 等. 油菜联合收获机集成式纵轴流脱离装置设计与试验[J]. 农业机械学报, 2017, 48(5): 108-116. |

| LI H T, WAN X Y, WANG H, et al. Design and experiment on integrated longitudinal axial flow threshing and separating device of rape combine harvester[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(5): 108-116. | |

| [9] | 关卓怀, 吴崇友, 王刚, 等. 油菜联合收割机双向电驱动分行竖割刀设计[J]. 农业工程学报, 2019, 35(3): 1-8. |

| GUAN Z H, WU C Y, WANG G, et al. Design of bidirectional electric driven side vertical cutter for rape combine harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(3): 1-8. | |

| [10] | 马丽娜, 魏俊逸, 黄小毛, 等. 4LL-1.5Y型履带式油菜联合收获机割台振动分析[J]. 安徽农业大学学报, 2019, 46(4): 723-727. |

| MA L N, WEI J Y, HUANG X M, et al. Vibration analysis of cutting table of 4LL-1.5Y crawler rape combine harvester[J]. Journal of Anhui Agricultural University, 2019, 46(4): 723-727. | |

| [11] | 宗望远, 黄小毛, 潘海兵, 等. 下落油菜籽粒在无秸秆正压纵向气流场中的漂移特性[J]. 农业工程学报, 2015, 31(3): 70-76. |

| ZONG W Y, HUANG X M, PAN H B, et al. Drifting property of falling oil rape seeds in longitudinal positive pressure airflow field without stalks[J]. Transactions of the Chinese Society of Agricultural Engineering, 2015, 31(3): 70-76. | |

| [12] | 黄小毛, 查显涛, 宗望远, 等. 油菜联合收获割台落粒横流气压收集装置设计与试验[J]. 农业机械学报, 2016, 47(S1): 227-233. |

| HUANG X M, ZHA X T, ZONG W Y, et al. Design and test of an air-pressure collection device for fallen-grain crossflow in the cutting table of oilseed rape combine harvesters[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(S1): 227-233. | |

| [13] | 李毅念, 易应武, 杜世伟, 等. 小区谷物联合收获机气吹式割台设计与试验[J]. 农业机械学报, 2017, 48(6): 79-87. |

| LI Y N, YI Y W, DU S W, et al. Design and experiment on air blowing header of plot combine harvester for grain[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(6): 79-87. | |

| [14] | 王朕, 黄浩, 易应武, 等. 小型油菜联合收割机吹禾气流管道结构优化设计与试验[J]. 中国农机化学报, 2020, 41(9): 16-24. |

| WANG Z, HUANG H, YI Y W, et al. Optimization design and test of air-flow pipe structure in small-scale rape combined harvester[J]. Journal of Chinese Agricultural Mechanization, 2020, 41(9): 16-24. | |

| [15] | 关卓怀, 江涛, 沐森林, 等. 正负气压式油菜割台分行落粒回收装置设计与试验[J]. 农业机械学报, 2022, 53(7): 103-112. |

| GUAN Z H, JIANG T, MU S L, et al. Development and test of positive and negative pressure combined side knife cutting scattered seed recovery device for rapeseed header[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(7): 103-112. | |

| [16] | 陈子民, 莫江婷, 陈广生, 等. 基于Fluent的顶风式热泵干燥箱气流场分析及优化[J]. 中国农业科技导报, 2024, 26(10): 135-144. |

| CHEN Z M, MO J T, CHEN G S, et al. Analysis and optimization of the airflow field in a head-air heat pump dryer based on fluent[J]. Journal of Agricultural Science and Technology, 2024, 26(10): 135-144. | |

| [17] | 李衍军, 刘瑞, 刘春晓, 等. 气送式排种器输种管内种子速度耦合仿真测定与试验[J]. 农业机械学报, 2021, 52(4): 54-61. |

| LI Y J, LIU R, LIU C X, et al. Simulation and test of seed velocity coupling in seed tube of pneumutic seed metering device[J]. Transactions of the Chinese Society for Agricultural Machinery, 2021, 52(4): 54-61. | |

| [18] | 陈树人, 肖君, 饶师任, 等. 黄花苜蓿收获机吹送装置气流速度场CFD分析[J]. 农业工程学报, 2016, 32(12): 39-46. |

| CHEN S R, XIAO J, RAO S R, et al. CFD numerical analysis of airflow blowing velocity-field of Medicago hispida harvester[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(12): 39-46. | |

| [19] | 邱威, 丁为民, 傅锡敏, 等. 果园喷雾机圆环双流道风机的设计与试验[J]. 农业工程学报, 2012, 28(12): 13-17. |

| QIU W, DING W M, FU X M, et al. Design and experiment of ring double-channel fan for spraying machine in orchard[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(12): 13-17. | |

| [20] | 邱威, 缪佳佳, 李小龙, 等. 果园多通道定向风送雾化装置设计与试验[J]. 南京农业大学学报, 2020, 43(3): 547-555. |

| QIU W, MIAO J J, LI X L, et al. Design and experiment of multi-channel directional atomizer for orchard sprayer[J]. Journal of Nanjing Agricultural University, 2020, 43(3): 547-555. | |

| [21] | 邱威, 邬伊浩, 周慧能, 等. 温室风幕式施药装置设计与试验[J]. 南京农业大学学报, 2023, 46(2): 405-415. |

| QIU W, WU Y H, ZHOU H N, et al. Design and test of greenhouse air curtain spraying device[J]. Journal of Nanjing Agricultural University, 2023, 46(2): 405-415. | |

| [22] | 吴崇友, 肖圣元, 金梅. 油菜联合收获与分段收获效果比较[J]. 农业工程学报, 2014, 30(17): 10-16. |

| WU C Y, XIAO S Y, JIN M. Comparation on rape combine harvesting and two-stage harvesting[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(17): 10-16. | |

| [23] | 冯健, 李丹阳, 吴传云, 等. 油菜籽联合收获机作业效果综合测评[J]. 中国农机化学报, 2023, 44(1): 65-68. |

| FENG J, LI D Y, WU C Y, et al. Comprehensive testing on working effects of the rapeseed combine harvesters[J]. Journal of Chinese Agricultural Mechanization, 2023, 44(1): 65-68. | |

| [24] | 吴传云, 冯健, 陈兴和, 等. 油菜联合机收与分段机收作业效果综合测评[J]. 中国农机化学报, 2024, 45(2): 1-6. |

| WU C Y, FENG J, CHEN X H, et al. Comprehensive evaluation of the effectiveness of combined and segmented rapeseedharvesting operations[J]. Journal of Chinese Agricultural Mechanization, 2024, 45(2): 1-6. |

| [1] | 董智超, 岳宁燕, 吕魏, 余晓燚, 郑凯文, 宋海星, 陈海飞. 高、低含油量油菜品种的产量、品质和氮利用效率对施氮量的响应差异[J]. 浙江农业学报, 2025, 37(5): 998-1008. |

| [2] | 裴大妹, 赵洪平, 王龙, 李华欣, 赵志, 肖麓. 白菜型油菜分枝角度主基因+多基因混合遗传模型分析[J]. 浙江农业学报, 2025, 37(4): 745-753. |

| [3] | 陈威, 朱怡航, 顾清, 林宝刚, 张小斌. 基于机器视觉和YOLOv5的油菜角果表型参数分析[J]. 浙江农业学报, 2024, 36(6): 1379-1388. |

| [4] | 沈宇峰, 罗海峰, 吴明亮, 官春云. 油菜脱出物双向切流喂入式旋风分离清选装置的设计与试验[J]. 浙江农业学报, 2023, 35(5): 1178-1186. |

| [5] | 姚彦林, 马骊, 刘丽君, 蒲媛媛, 李学才, 王旺田, 方彦, 孙万仓, 武军艳. 白菜型油菜开花调控基因BrFT的生物信息学特性和表达分析[J]. 浙江农业学报, 2023, 35(5): 992-1000. |

| [6] | 徐洋, 任奕林, 王浩杰, 黄秋航, 邢博源, 曹红亮. 不同制备条件下油菜秸秆生物炭用作缓释载体的综合评价[J]. 浙江农业学报, 2023, 35(4): 893-902. |

| [7] | 许耀照, 曾秀存, 王振朝, 党仕卓, 刘永晶. NaCl胁迫对冬油菜种子萌发和生理特性的影响[J]. 浙江农业学报, 2023, 35(3): 499-508. |

| [8] | 郎春秀, 刘仁虎, 郑滔, 王伏林, 石江华, 胡张华, 吴关庭. 化学诱变获得甘蓝型油菜矮秆突变新种质[J]. 浙江农业学报, 2023, 35(11): 2516-2524. |

| [9] | 李虹桥, 赖莹, 母娜, 严红梅, 汤维群, 蒋小灵, 高雯, 吴永成. 密度对不同株高油菜冠层结构与群体光合能力的影响[J]. 浙江农业学报, 2022, 34(3): 419-427. |

| [10] | 冯玮, 李朋朋, 宋鹏. 甘蓝型油菜Kunitz蛋白酶抑制剂的异源表达与理化特征分析[J]. 浙江农业学报, 2022, 34(1): 112-119. |

| [11] | 陈纪鹏, 刘小林, 李生强, 刘显军, 胡月清, 陈桃. 白菜型油菜黄芽白与甘蓝型油菜湘油15种间杂交及其杂种后代的遗传学特征[J]. 浙江农业学报, 2021, 33(7): 1170-1176. |

| [12] | 李诗涛, 张王菲, 赵丽仙, 王熙媛. 基于时序PolSAR影像与决策树模型的油菜物候期识别[J]. 浙江农业学报, 2021, 33(11): 2116-2127. |

| [13] | 练华山, 李欣欣, 林立金, 廖明安. 表油菜素内酯对夏黑葡萄幼苗生长的影响[J]. 浙江农业学报, 2021, 33(10): 1889-1896. |

| [14] | 熊廷浩, 黄益国, 周旋, 鲁艳红, 资涛, 胡宇倩, 宋海星. 湖南省油菜主产区土壤养分含量与重金属污染风险评价[J]. 浙江农业学报, 2021, 33(10): 1904-1912. |

| [15] | 张仕林, 戴飞, 赵武云, 田斌, 陈邦善. 青稞联合收获机配套秸秆打捆装置设计与试验[J]. 浙江农业学报, 2020, 32(7): 1289-1301. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||