浙江农业学报 ›› 2025, Vol. 37 ›› Issue (11): 2376-2386.DOI: 10.3969/j.issn.1004-1524.20241129

基于离散元法的水稻种子参数标定与旱作排种仿真

- 1.昆明理工大学,机电工程学院,云南 昆明 650500

2.红河学院,工学院,云南 红河 661199

3.红河学院 高原农机机电一体化技术研究与应用工程研究中心,云南 红河 661199

-

收稿日期:2024-12-30出版日期:2025-11-25发布日期:2025-12-08 -

作者简介:杨锦皓(1999—),男,云南昆明人,硕士研究生,研究方向为农业机械设计、结构分析。E-mail:2420465039@qq.com -

通讯作者:*江洁,E-mail:57224911@qq.com -

基金资助:云南省高等学校工程研究中心建设项目(01610001845);云南省高校创新团队专项(01610001508);云南省高校实验室项目(01610001478)

Calibration of rice seed parameters and simulation of dry direct-seeding based on the discrete element method

YANG Jinhao1( ), JIANG Jie2,3,*(

), JIANG Jie2,3,*( ), LIU Hang1, LI Fuqiang1

), LIU Hang1, LI Fuqiang1

- 1. School of Mechanical and Electrical Engineering, Kunming University of Science and Technology, Kunming 650500, China

2. School of Engineering, Honghe University, Honghe 661199, Yunnan, China

3. High Altitude Agricultural Machinery Mechatronics Technology Research and Application Engineering Research Center, Honghe University, Honghe 661199, Yunnan, China

-

Received:2024-12-30Online:2025-11-25Published:2025-12-08

摘要:

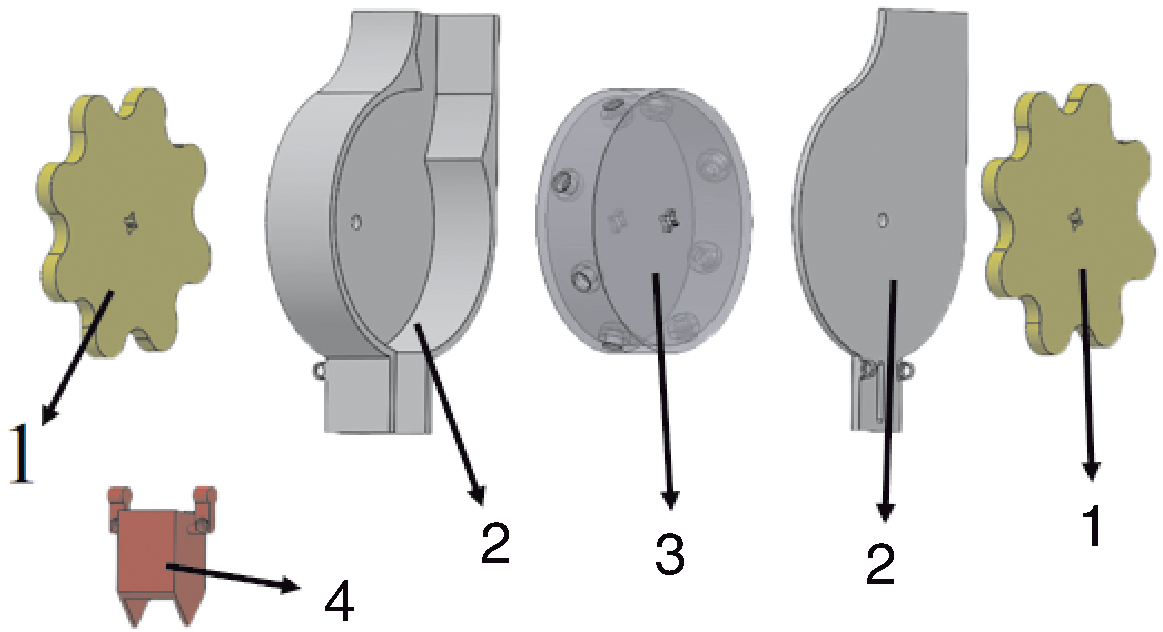

为解决云南地区水稻旱播作业中精量成穴与覆膜后排种的技术需求,本研究旨在设计一款与之相适应的排种器。首先,测量稻种的三轴尺寸,计算出稻种密度为1 036 kg·m-3;使用万能试验机进行压缩试验,测得稻种的泊松比为0.30、剪切模量为108 MPa。进而,选用尼龙-66作为排种器材料,搭建物理实验台,获得稻种与尼龙-66的碰撞恢复系数为0.48、静摩擦系数为0.53、滚动摩擦系数为0.07。然后,采用离散元法建立稻种模型,并基于EDEM与Design-Expert软件对种子间接触参数进行标定,获得最优稻种间接触参数组合(碰撞恢复系数0.34、静摩擦系数0.66、滚动摩擦系数0.078)。以此为基础,设计排种器,开展排种器取种与排种过程的仿真分析,确定排种器的较优转速为90~110(°)·s-1。采用尼龙-66材料制作排种器并搭建排种试验台进行验证。试验结果表明,该排种器在成穴性能与刺膜播种效果方面均表现良好,能够满足水稻旱播的农艺要求。

中图分类号:

引用本文

杨锦皓, 江洁, 刘行, 李福强. 基于离散元法的水稻种子参数标定与旱作排种仿真[J]. 浙江农业学报, 2025, 37(11): 2376-2386.

YANG Jinhao, JIANG Jie, LIU Hang, LI Fuqiang. Calibration of rice seed parameters and simulation of dry direct-seeding based on the discrete element method[J]. Acta Agriculturae Zhejiangensis, 2025, 37(11): 2376-2386.

| 尺寸 Size | 最大值 Maximum | 最小值 Minimum | 平均值 Average value |

|---|---|---|---|

| 长Length | 9.72 | 8.44 | 9.18 |

| 宽Width | 2.90 | 2.46 | 2.66 |

| 厚Thickness | 2.24 | 1.70 | 2.00 |

表1 稻种的三轴尺寸

Table 1 Triaxial size of rice seeds mm

| 尺寸 Size | 最大值 Maximum | 最小值 Minimum | 平均值 Average value |

|---|---|---|---|

| 长Length | 9.72 | 8.44 | 9.18 |

| 宽Width | 2.90 | 2.46 | 2.66 |

| 厚Thickness | 2.24 | 1.70 | 2.00 |

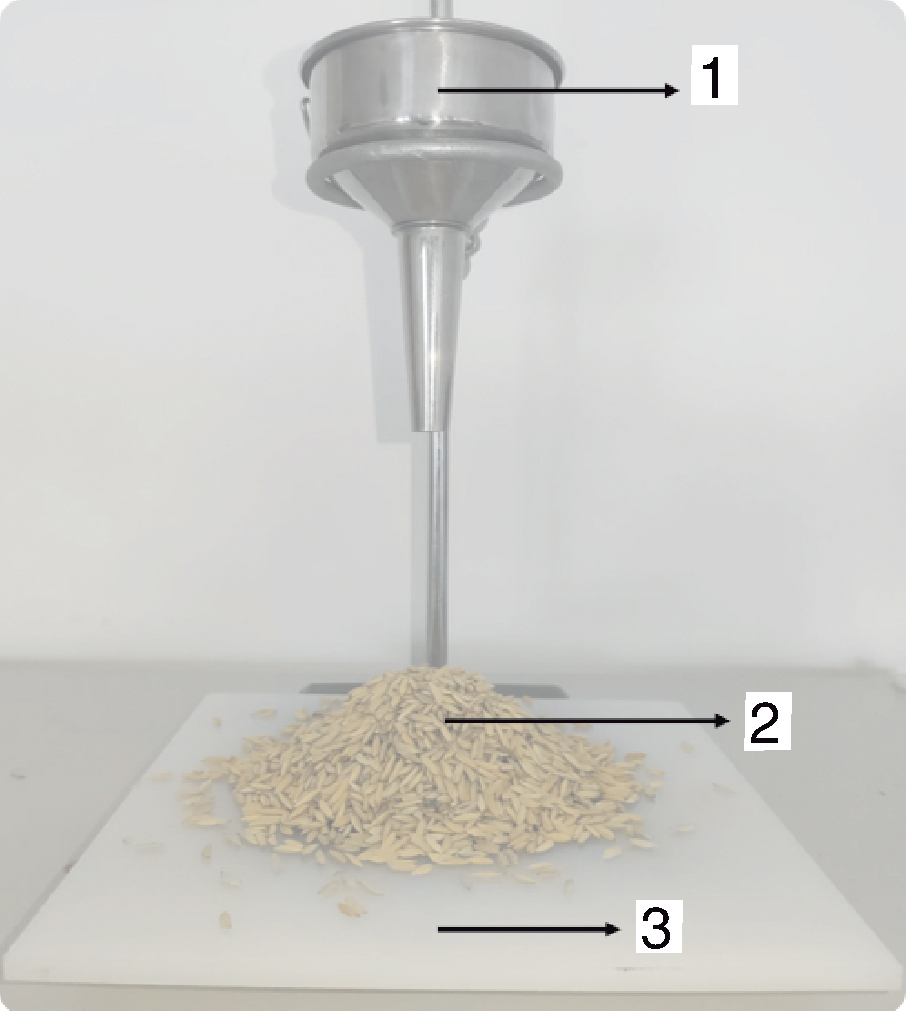

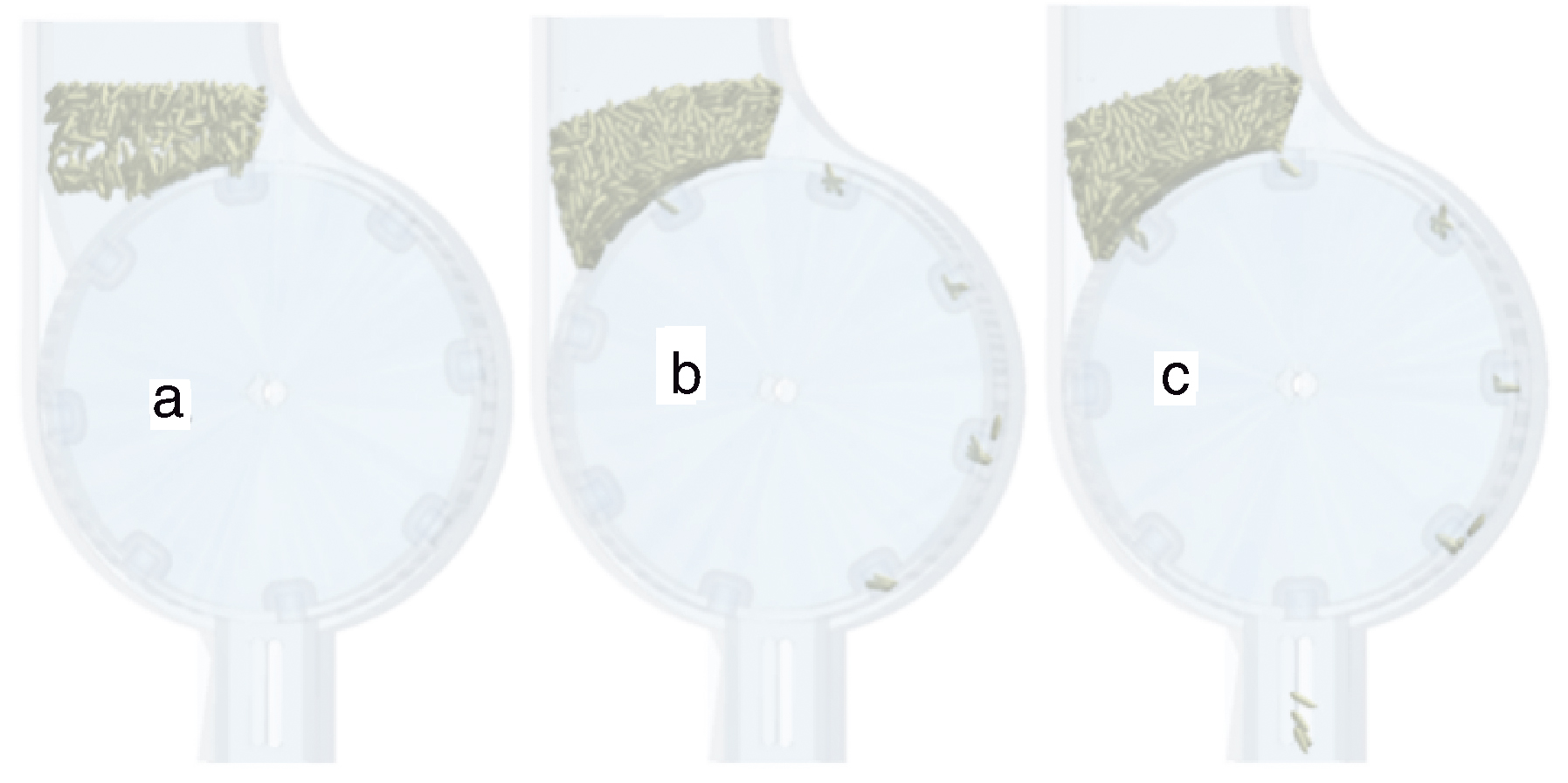

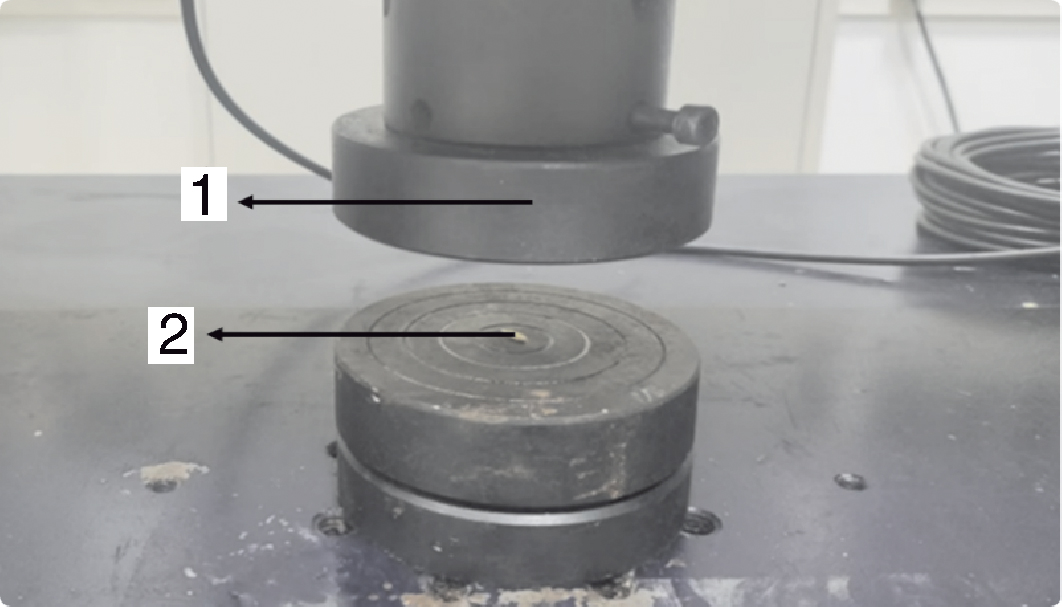

图1 万能试验机单轴压缩试验图 1,万能试验机平板压头;2,试验稻种。

Fig.1 Uniaxial compression test of universal testing machine 1, The flat test head of the universal testing machine; 2, Test rice seed.

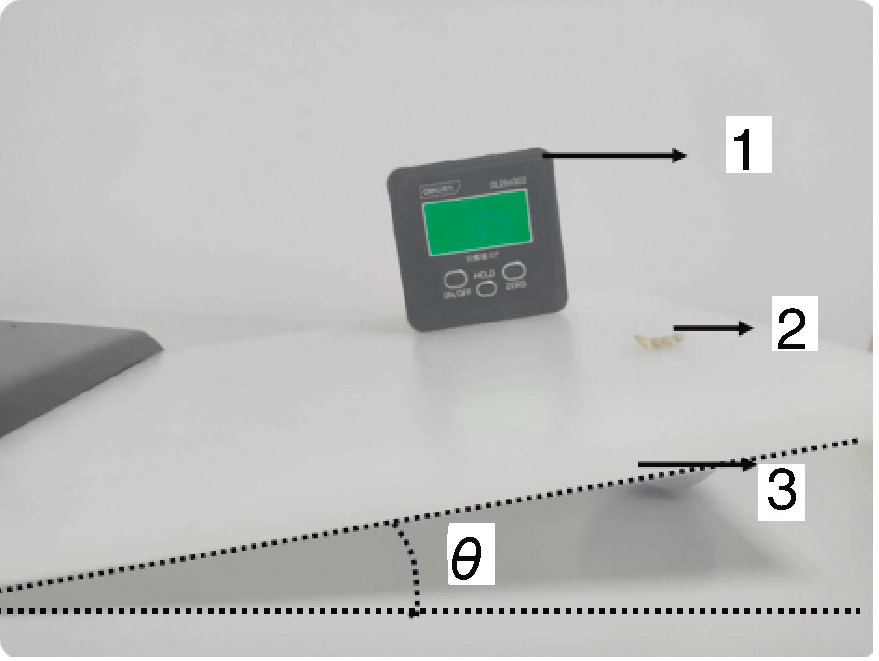

图3 静摩擦系数试验台 1为倾角仪;2为稻种;3为尼龙板;θ为稻种滑动时倾角仪角度。

Fig.3 Test bench for coefficient of static friction 1 is the inclinometer; 2 is the rice seed; 3 is the nylon plate; θ is the angle of the inclinometer when the rice seed slides.

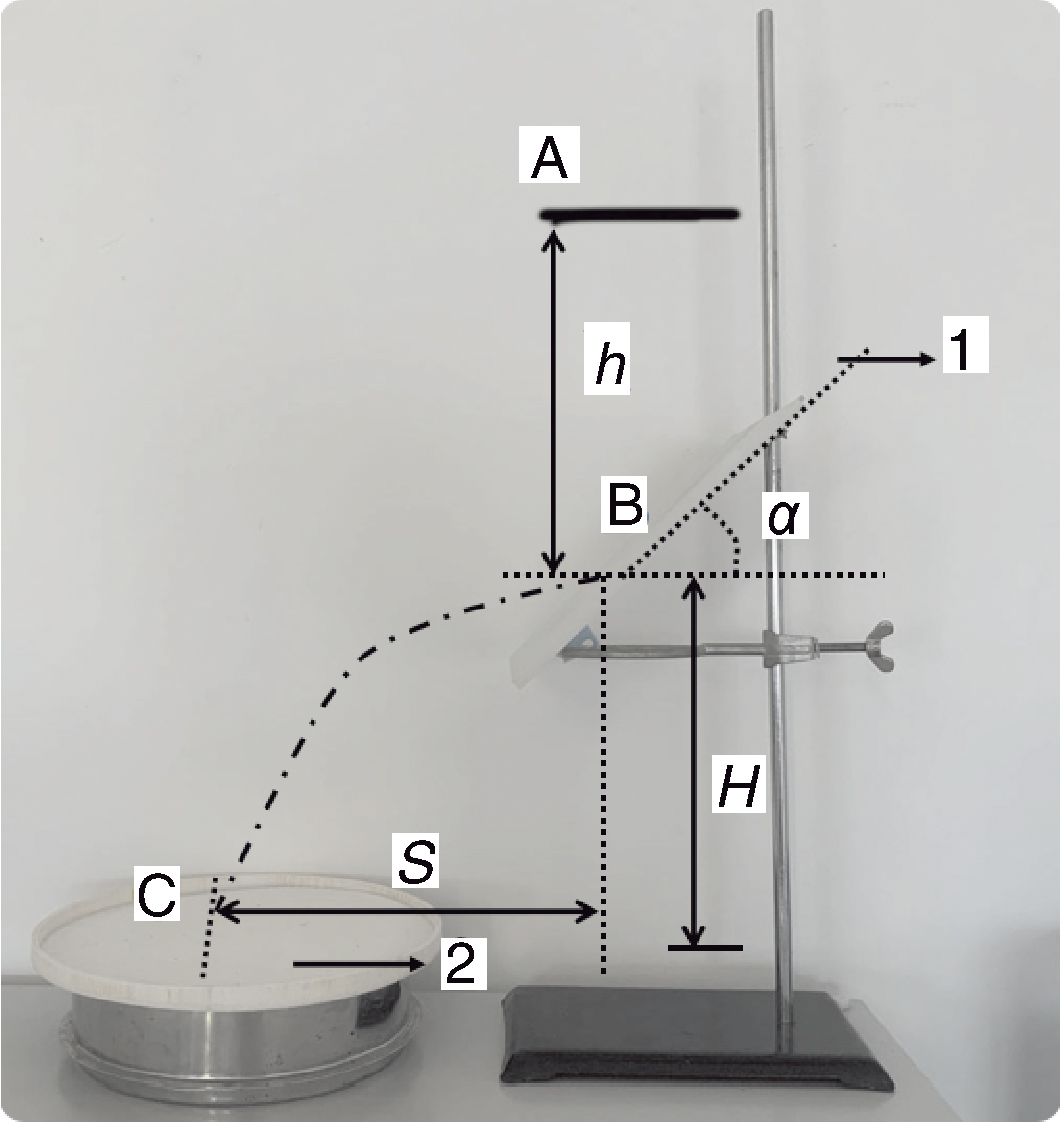

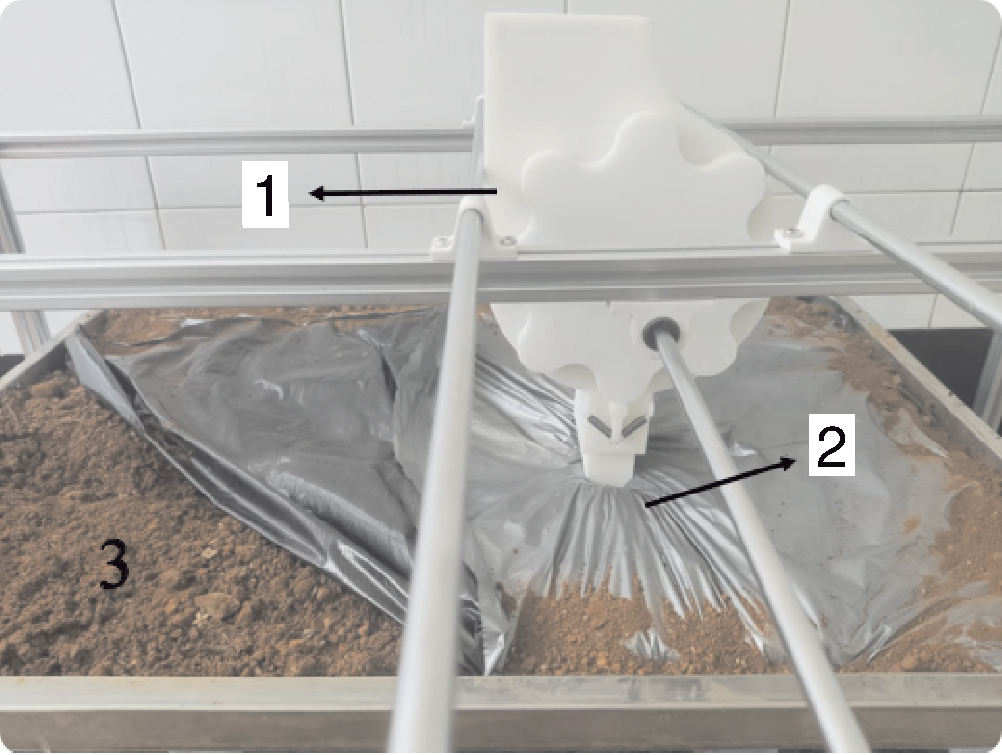

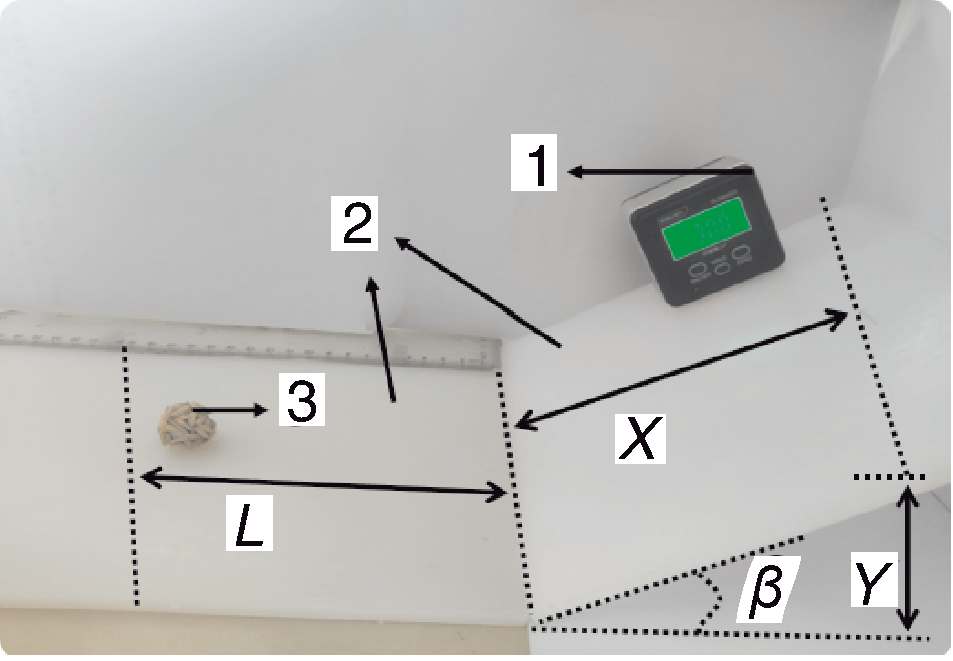

图4 滚动摩擦因素试验台 1为倾角仪;2为尼龙板;3为稻种球。Y代表稻种球初始高度;X代表稻种球在斜板上滚动的位移;L代表稻种球在平板上滚动的位移;β代表斜板倾角,(°)。

Fig.4 Rolling friction factor test bench 1 is the inclinometer; 2 is the nylon plate; 3 is the rice seed ball. Y denotes the initial height of the rice seed ball; X indicates the displacement of the rice seed ball rolling on the inclined plate; L represents the displacement of the rice seed ball rolling on the flat plate; β denotes the inclination angle of the inclined plate, (°).

| 序号 No. | 左侧角度 Left side angle/(°) | 右侧角度 Right side angle/(°) |

|---|---|---|

| 1 | 32.28 | 32.17 |

| 2 | 32.52 | 32.65 |

| 3 | 31.84 | 31.45 |

| 4 | 31.52 | 32.58 |

| 5 | 32.24 | 32.92 |

| 6 | 32.16 | 29.91 |

| 7 | 32.00 | 31.70 |

| 8 | 30.84 | 32.48 |

| 9 | 32.63 | 32.26 |

| 10 | 31.23 | 31.70 |

| 平均Average | 31.93 | 31.98 |

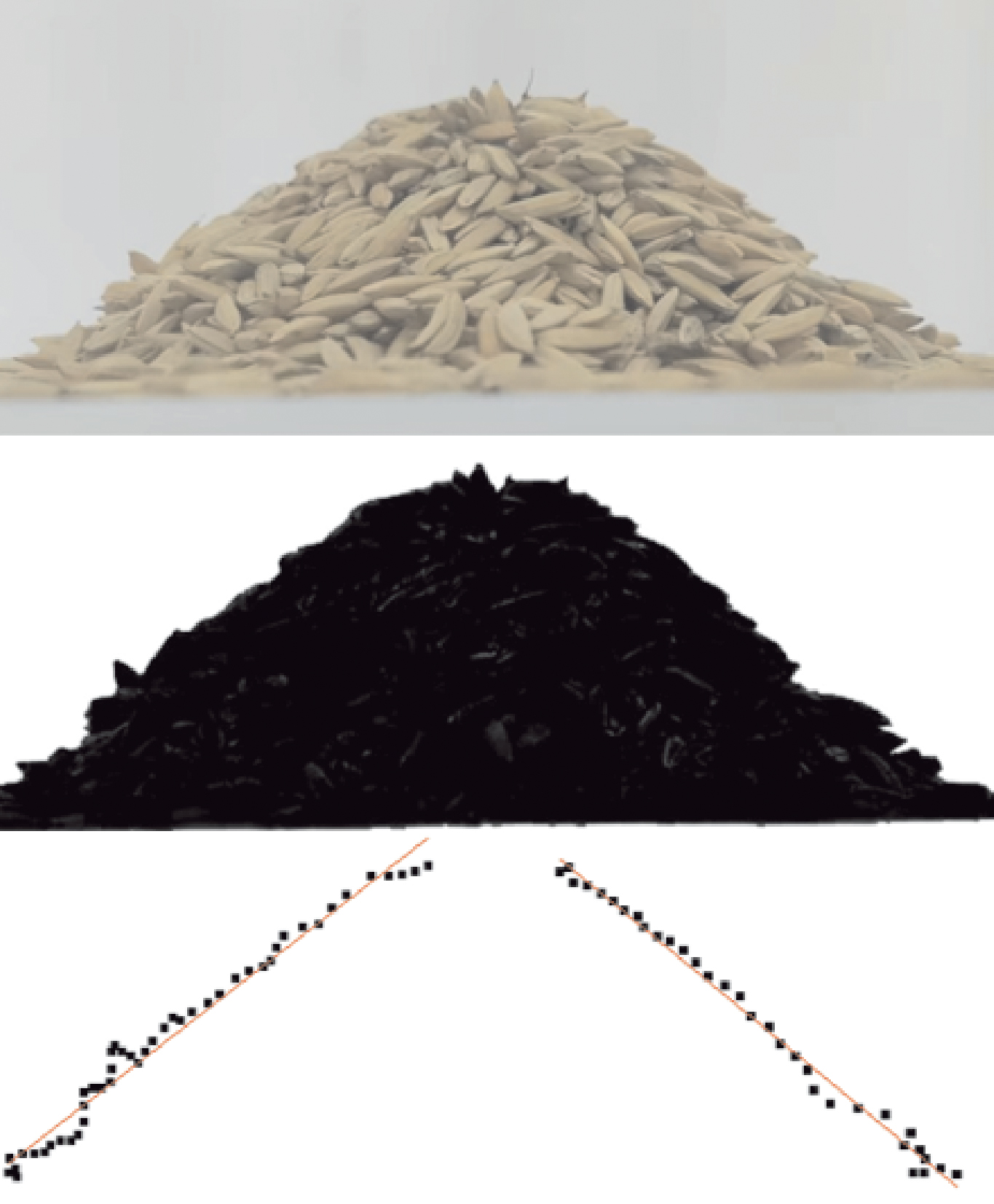

表2 堆积角度表

Table 2 Stacking angle table

| 序号 No. | 左侧角度 Left side angle/(°) | 右侧角度 Right side angle/(°) |

|---|---|---|

| 1 | 32.28 | 32.17 |

| 2 | 32.52 | 32.65 |

| 3 | 31.84 | 31.45 |

| 4 | 31.52 | 32.58 |

| 5 | 32.24 | 32.92 |

| 6 | 32.16 | 29.91 |

| 7 | 32.00 | 31.70 |

| 8 | 30.84 | 32.48 |

| 9 | 32.63 | 32.26 |

| 10 | 31.23 | 31.70 |

| 平均Average | 31.93 | 31.98 |

| 参数 Parameter | 低水平(-1) Low(-1) | 高水平(+1) High(+1) |

|---|---|---|

| X1 | 0.30 | 0.80 |

| X2 | 0.25 | 0.80 |

| X3 | 0.30 | 0.13 |

| X4 | 0.30 | 0.60 |

| X5 | 0.30 | 0.75 |

| X6 | 0.01 | 0.15 |

表3 B-P筛选试验参数

Table 3 Plackett-Burman test parameters

| 参数 Parameter | 低水平(-1) Low(-1) | 高水平(+1) High(+1) |

|---|---|---|

| X1 | 0.30 | 0.80 |

| X2 | 0.25 | 0.80 |

| X3 | 0.30 | 0.13 |

| X4 | 0.30 | 0.60 |

| X5 | 0.30 | 0.75 |

| X6 | 0.01 | 0.15 |

| 序号No. | X1 | X2 | X3 | X4 | X5 | X6 | ϑ/(°) |

|---|---|---|---|---|---|---|---|

| 1 | -1 | -1 | -1 | -1 | -1 | -1 | 8.16 |

| 2 | 1 | 1 | -1 | 1 | 1 | 1 | 38.21 |

| 3 | 1 | -1 | -1 | -1 | 1 | -1 | 33.24 |

| 4 | -1 | 1 | 1 | 1 | -1 | -1 | 13.26 |

| 5 | 1 | 1 | -1 | -1. | -1 | 1 | 27.53 |

| 6 | 1 | 1 | 1 | -1 | -1 | -1 | 17.58 |

| 7 | -1 | 1 | 1 | -1 | 1 | 1 | 40.93 |

| 8 | 1 | -1 | 1 | 1 | 1 | -1 | 21.15 |

| 9 | -1 | -1 | 1 | -1 | 1 | 1 | 37.93 |

| 10 | 1 | -1 | 1 | 1 | -1 | 1 | 19.07 |

| 11 | -1 | 1 | -1 | 1 | 1 | -1 | 26.34 |

| 12 | -1 | -1 | -1 | 1 | -1 | 1 | 14.83 |

表4 B-P筛选试验与结果

Table 4 Plackett-Burman tests and results

| 序号No. | X1 | X2 | X3 | X4 | X5 | X6 | ϑ/(°) |

|---|---|---|---|---|---|---|---|

| 1 | -1 | -1 | -1 | -1 | -1 | -1 | 8.16 |

| 2 | 1 | 1 | -1 | 1 | 1 | 1 | 38.21 |

| 3 | 1 | -1 | -1 | -1 | 1 | -1 | 33.24 |

| 4 | -1 | 1 | 1 | 1 | -1 | -1 | 13.26 |

| 5 | 1 | 1 | -1 | -1. | -1 | 1 | 27.53 |

| 6 | 1 | 1 | 1 | -1 | -1 | -1 | 17.58 |

| 7 | -1 | 1 | 1 | -1 | 1 | 1 | 40.93 |

| 8 | 1 | -1 | 1 | 1 | 1 | -1 | 21.15 |

| 9 | -1 | -1 | 1 | -1 | 1 | 1 | 37.93 |

| 10 | 1 | -1 | 1 | 1 | -1 | 1 | 19.07 |

| 11 | -1 | 1 | -1 | 1 | 1 | -1 | 26.34 |

| 12 | -1 | -1 | -1 | 1 | -1 | 1 | 14.83 |

| 参数 Parameter | 效应 Effect | 均方和 Sum of square | 影响率 Impact rate/% | 显著性排序 Sgnificant sorting |

|---|---|---|---|---|

| X1 | 2.555 00 | 19.584 10 | 1.475 27 | 5 |

| X2 | 4.911 67 | 72.373 40 | 5.451 91 | 4 |

| X3 | 0.268 333 | 0.216 00 | 0.016 27 | 6 |

| X4 | -5.418 33 | 88.075 00 | 6.634 71 | 3 |

| X5 | 16.228 30 | 790.076 00 | 59.576 70 | 1 |

| X6 | 9.795 00 | 287.826 00 | 21.682 00 | 2 |

表5 B-P筛选试验参数的显著性分析

Table 5 Significance analysis of Plackett-Burman test parameters

| 参数 Parameter | 效应 Effect | 均方和 Sum of square | 影响率 Impact rate/% | 显著性排序 Sgnificant sorting |

|---|---|---|---|---|

| X1 | 2.555 00 | 19.584 10 | 1.475 27 | 5 |

| X2 | 4.911 67 | 72.373 40 | 5.451 91 | 4 |

| X3 | 0.268 333 | 0.216 00 | 0.016 27 | 6 |

| X4 | -5.418 33 | 88.075 00 | 6.634 71 | 3 |

| X5 | 16.228 30 | 790.076 00 | 59.576 70 | 1 |

| X6 | 9.795 00 | 287.826 00 | 21.682 00 | 2 |

| 序号No. | X4 | X5 | X6 | ϑ/(°) | ξ /% |

|---|---|---|---|---|---|

| 1 | 0.65 | 0.25 | 0.02 | 13.17 | 58.79 |

| 2 | 0.55 | 0.4 | 0.04 | 23.34 | 26.95 |

| 3 | 0.45 | 0.55 | 0.06 | 27.21 | 14.85 |

| 4 | 0.35 | 0.70 | 0.08 | 31.71 | 0.75 |

| 5 | 0.25 | 0.85 | 0.10 | 35.18 | 10.09 |

表6 最陡爬坡试验

Table 6 Steepest climb test

| 序号No. | X4 | X5 | X6 | ϑ/(°) | ξ /% |

|---|---|---|---|---|---|

| 1 | 0.65 | 0.25 | 0.02 | 13.17 | 58.79 |

| 2 | 0.55 | 0.4 | 0.04 | 23.34 | 26.95 |

| 3 | 0.45 | 0.55 | 0.06 | 27.21 | 14.85 |

| 4 | 0.35 | 0.70 | 0.08 | 31.71 | 0.75 |

| 5 | 0.25 | 0.85 | 0.10 | 35.18 | 10.09 |

| 序号No. | X4 | X5 | X6 | ϑ /(°) | ξ /% |

|---|---|---|---|---|---|

| 1 | 0 | 1 | 1 | 34.26 | 7.23 |

| 2 | 0 | -1 | 1 | 32.26 | 2.18 |

| 3 | 1 | 0. | 1 | 32.57 | 1.94 |

| 4 | 1 | 1 | 0 | 33.71 | 5.49 |

| 5 | 0 | 1 | -1 | 31.64 | 0.99 |

| 6 | -1 | 1 | 0 | 34.01 | 6.43 |

| 7 | 0 | 0 | 0 | 32.14 | 0.59 |

| 8 | 1 | -1 | 0 | 29.57 | 7.46 |

| 9 | -1 | 0 | 1 | 34.57 | 8.18 |

| 10 | 0 | 0 | 0 | 32.74 | 2.47 |

| 11 | -1 | -1 | 0 | 31.84 | 0.36 |

| 12 | 0 | 0 | 0 | 31.51 | 1.39 |

| 13 | -1 | 0 | -1 | 30.06 | 5.93 |

| 14 | 0 | -1 | -1 | 27.33 | 14.46 |

| 15 | 0 | 0 | 0 | 31.66 | 0.91 |

| 16 | 1 | 0 | -1 | 29.98 | 6.17 |

| 17 | 0 | 0 | 0 | 32.18 | 0.70 |

表7 响应面(B-B)试验设计方案与结果

Table 7 Box-Behnken trial design and results

| 序号No. | X4 | X5 | X6 | ϑ /(°) | ξ /% |

|---|---|---|---|---|---|

| 1 | 0 | 1 | 1 | 34.26 | 7.23 |

| 2 | 0 | -1 | 1 | 32.26 | 2.18 |

| 3 | 1 | 0. | 1 | 32.57 | 1.94 |

| 4 | 1 | 1 | 0 | 33.71 | 5.49 |

| 5 | 0 | 1 | -1 | 31.64 | 0.99 |

| 6 | -1 | 1 | 0 | 34.01 | 6.43 |

| 7 | 0 | 0 | 0 | 32.14 | 0.59 |

| 8 | 1 | -1 | 0 | 29.57 | 7.46 |

| 9 | -1 | 0 | 1 | 34.57 | 8.18 |

| 10 | 0 | 0 | 0 | 32.74 | 2.47 |

| 11 | -1 | -1 | 0 | 31.84 | 0.36 |

| 12 | 0 | 0 | 0 | 31.51 | 1.39 |

| 13 | -1 | 0 | -1 | 30.06 | 5.93 |

| 14 | 0 | -1 | -1 | 27.33 | 14.46 |

| 15 | 0 | 0 | 0 | 31.66 | 0.91 |

| 16 | 1 | 0 | -1 | 29.98 | 6.17 |

| 17 | 0 | 0 | 0 | 32.18 | 0.70 |

| 来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | p值 p value |

|---|---|---|---|---|

| 模型Model | 54.510 0 | 9 | 6.060 0 | <0.000 1 |

| X4 | 2.700 0 | 1 | 2.700 0 | 0.003 4 |

| X5 | 19.910 0 | 1 | 19.910 0 | <0.000 1 |

| X6 | 26.830 0 | 1 | 26.830 0 | <0.000 1 |

| X4X5 | 0.970 2 | 1 | 0.970 2 | 0.035 1 |

| X4X6 | 0.921 6 | 1 | 0.921 6 | 0.038 7 |

| X5X6 | 1.330 0 | 1 | 1.330 0 | 0.018 4 |

| 0.457 1 | 1 | 0.457 1 | 0.116 8 | |

| 0.036 4 | 1 | 0.036 4 | 0.629 1 | |

| 1.420 0 | 1 | 1.420 0 | 0.016 1 | |

| 残差Residual | 1.000 0 | 7 | ||

| 失拟项Lack of fit | 0.055 3 | 3 | 0.078 1 | 0.968 5 |

| 纯误差Pure error | 0.944 7 | 4 | 0.236 2 | |

| 总和Cor total | 55.510 0 | 16 |

表8 响应面(B-B)试验模型方差分析

Table 8 Analysis of variance of the Box-Behnken test model

| 来源 Source | 平方和 Sum of squares | 自由度 Degree of freedom | 均方 Mean square | p值 p value |

|---|---|---|---|---|

| 模型Model | 54.510 0 | 9 | 6.060 0 | <0.000 1 |

| X4 | 2.700 0 | 1 | 2.700 0 | 0.003 4 |

| X5 | 19.910 0 | 1 | 19.910 0 | <0.000 1 |

| X6 | 26.830 0 | 1 | 26.830 0 | <0.000 1 |

| X4X5 | 0.970 2 | 1 | 0.970 2 | 0.035 1 |

| X4X6 | 0.921 6 | 1 | 0.921 6 | 0.038 7 |

| X5X6 | 1.330 0 | 1 | 1.330 0 | 0.018 4 |

| 0.457 1 | 1 | 0.457 1 | 0.116 8 | |

| 0.036 4 | 1 | 0.036 4 | 0.629 1 | |

| 1.420 0 | 1 | 1.420 0 | 0.016 1 | |

| 残差Residual | 1.000 0 | 7 | ||

| 失拟项Lack of fit | 0.055 3 | 3 | 0.078 1 | 0.968 5 |

| 纯误差Pure error | 0.944 7 | 4 | 0.236 2 | |

| 总和Cor total | 55.510 0 | 16 |

| 尺寸 Size/mm | 取种速度 Seed retrieval speed/[(°)·s-1] | 合格穴率 Qualified rate/% |

|---|---|---|

| 9.5 | 60 | 68 |

| 90 | 71 | |

| 120 | 74 | |

| 9.7 | 60 | 76 |

| 90 | 81 | |

| 120 | 83 | |

| 1.0 | 60 | 70 |

| 90 | 73 | |

| 120 | 73 |

表9 取种槽优化仿真试验

Table 9 Optimization simulation test of seed trough

| 尺寸 Size/mm | 取种速度 Seed retrieval speed/[(°)·s-1] | 合格穴率 Qualified rate/% |

|---|---|---|

| 9.5 | 60 | 68 |

| 90 | 71 | |

| 120 | 74 | |

| 9.7 | 60 | 76 |

| 90 | 81 | |

| 120 | 83 | |

| 1.0 | 60 | 70 |

| 90 | 73 | |

| 120 | 73 |

| 取种速度 Seed retrieval speed/ [(°)·s-1] | 2粒稻种穴占比 Proportion of 2-seed holes/% | 合格穴占比 Proportion of qualified holes/% | 6粒稻种穴占比 Proportion of 6-seed holes/% |

|---|---|---|---|

| 60 | 2 | 75 | 23 |

| 90 | 5 | 81 | 15 |

| 110 | 7 | 84 | 9 |

| 120 | 12 | 82 | 6 |

表10 排种仿真结果

Table 10 Seeding simulation results

| 取种速度 Seed retrieval speed/ [(°)·s-1] | 2粒稻种穴占比 Proportion of 2-seed holes/% | 合格穴占比 Proportion of qualified holes/% | 6粒稻种穴占比 Proportion of 6-seed holes/% |

|---|---|---|---|

| 60 | 2 | 75 | 23 |

| 90 | 5 | 81 | 15 |

| 110 | 7 | 84 | 9 |

| 120 | 12 | 82 | 6 |

| 取种速度 Seed retrieval speed/[(°)·s-1] | 合格穴率 Qualified rate/% | 刺膜合格率 Puncture pass rate/% |

|---|---|---|

| 90 | 83 | 95 |

| 100 | 86 | 93 |

| 110 | 86 | 90 |

表11 排种试验结果

Table 11 Results of seed row experiment

| 取种速度 Seed retrieval speed/[(°)·s-1] | 合格穴率 Qualified rate/% | 刺膜合格率 Puncture pass rate/% |

|---|---|---|

| 90 | 83 | 95 |

| 100 | 86 | 93 |

| 110 | 86 | 90 |

| [1] | 沈国春, 魏旭东, 李宏博, 等. 分析水稻旱播水管技术的优点及应用现状[J]. 农业与技术, 2016, 36(6): 122. |

| SHEN G C, WEI X D, LI H B, et al. The advantages and application status of water pipe technology for dry seeding of rice were analyzed[J]. Agriculture and Technology, 2016, 36(6): 122. (in Chinese) | |

| [2] | 牟家宏, 杨发展, 杨云鹏, 等. 基于流固耦合仿真水稻种子建立与参数标定[J]. 农机化研究, 2022, 44(7): 14-20. |

| MOU J H, YANG F Z, YANG Y P, et al. Building and calibration of parameters of rice seeds for fluid-solid coupling simulation[J]. Journal of Agricultural Mechanization Research, 2022, 44(7): 14-20. (in Chinese with English abstract) | |

| [3] | REZVANI F, AZARGOSHASB H, JAMIALAHMADI O, et al. Experimental study and CFD simulation of phenol removal by immobilization of soybean seed coat in a packed-bed bioreactor[J]. Biochemical Engineering Journal, 2015, 101: 32-43. |

| [4] | HORABIK J, MOLENDA M. Parameters and contact models for DEM simulations of agricultural granular materials: a review[J]. Biosystems Engineering, 2016, 147: 206-225. |

| [5] | 鹿芳媛, 马旭, 谭穗妍, 等. 水稻芽种离散元主要接触参数仿真标定与试验[J]. 农业机械学报, 2018, 49(2): 93-99. |

| LU F Y, MA X, TAN S Y, et al. Simulative calibration and experiment on main contact parameters of discrete elements for rice bud seeds[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(2): 93-99. (in Chinese with English abstract) | |

| [6] | GONZÁLEZ-MONTELLANO C, FUENTES J M, AYUGA-TÉLLEZ E, et al. Determination of the mechanical properties of maize grains and olives required for use in DEM simulations[J]. Journal of Food Engineering, 2012, 111(4): 553-562. |

| [7] | COETZEE C J, ELS D N J. Calibration of discrete element parameters and the modelling of silo discharge and bucket filling[J]. Computers and Electronics in Agriculture, 2009, 65(2): 198-212. |

| [8] | 于庆旭, 刘燕, 陈小兵, 等. 基于离散元的三七种子仿真参数标定与试验[J]. 农业机械学报, 2020, 51(2): 123-132. |

| YU Q X, LIU Y, CHEN X B, et al. Calibration and experiment of simulation parameters for Panax notoginseng seeds based on DEM[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(2): 123-132. (in Chinese with English abstract) | |

| [9] | 贾富国, 韩燕龙, 刘扬, 等. 稻谷颗粒物料堆积角模拟预测方法[J]. 农业工程学报, 2014, 30(11): 254-260. |

| JIA F G, HAN Y L, LIU Y, et al. Simulation prediction method of repose angle for rice particle materials[J]. Transactions of the Chinese Society of Agricultural Engineering, 2014, 30(11): 254-260. (in Chinese with English abstract) | |

| [10] | MIYAMOTO T, NOGUCHI S, MATSUTOMO S. Numerical simulation and experimental verification for rice using distinct element method[M]//XIAO T, ZHANG L, FEI M. Communications in computer and Information Science, Heidelberg: Springer Berlin Heidelberg, 2012: 472-479. |

| [11] | 刘凡一, 张舰, 李博, 等. 基于堆积试验的小麦离散元参数分析及标定[J]. 农业工程学报, 2016, 32(12): 247-253. |

| LIU F Y, ZHANG J, LI B, et al. Calibration of parameters of wheat required in discrete element method simulation based on repose angle of particle heap[J]. Transactions of the Chinese Society of Agricultural Engineering, 2016, 32(12): 247-253. (in Chinese with English abstract) | |

| [12] | 陈圣家, 金涛, 李志刚, 等. 复杂应力状态下尼龙66力学性能研究[J]. 材料导报, 2016, 30(S2): 300-303. |

| CHEN S J, JIN T, LI Z G, et al. Mechanical properties of nylon 66 under complex stress[J]. Materials Reports, 2016, 30(S2): 300-303. (in Chinese) | |

| [13] | 任文涛, 董滨, 崔红光, 等. 水稻种子与斜面碰撞后运动规律的试验[J]. 农业工程学报, 2009, 25(7): 103-107. |

| REN W T, DONG B, CUI H G, et al. Experiment on the motion characteristics of rice seeds after collision with different slopes[J]. Transactions of the Chinese Society of Agricultural Engineering, 2009, 25(7): 103-107. (in Chinese with English abstract) | |

| [14] | 吴孟宸, 丛锦玲, 闫琴, 等. 花生种子颗粒离散元仿真参数标定与试验[J]. 农业工程学报, 2020, 36(23): 30-38. |

| WU M C, CONG J L, YAN Q, et al. Calibration and experiments for discrete element simulation parameters of peanut seed particles[J]. Transactions of the Chinese Society of Agricultural Engineering, 2020, 36(23): 30-38. (in Chinese with English abstract) | |

| [15] | 张胜伟, 张瑞雨, 陈天佑, 等. 绿豆种子离散元仿真参数标定与排种试验[J]. 农业机械学报, 2022, 53(3): 71-79. |

| ZHANG S W, ZHANG R Y, CHEN T Y, et al. Calibration of simulation parameters of mung bean seeds using discrete element method and verification of seed-metering test[J]. Transactions of the Chinese Society for Agricultural Machinery, 2022, 53(3): 71-79. (in Chinese with English abstract) | |

| [16] | 李大鹏. 气力式藜麦精量排种器离散元分析与性能试验研究[D]. 呼和浩特: 内蒙古农业大学, 2020. |

| LI D P. Discrete element analysis and performance test of pneumatic Chenopodium wheat precision metering device[D]. Hohhot: Inner Mongolia Agricultural University, 2020. (in Chinese with English abstract) | |

| [17] | 郑效帅, 何晓宁, 尚书旗, 等. 油莎豆种子籽粒离散元仿真参数标定与试验[J]. 农机化研究, 2024, 46(2): 172-178. |

| ZHENG X S, HE X N, SHANG S Q, et al. Calibration and experiments for discrete element simulation parameters of Cyperus esculentus seeds[J]. Journal of Agricultural Mechanization Research, 2024, 46(2): 172-178. (in Chinese with English abstract) | |

| [18] | 武涛, 黄伟凤, 陈学深, 等. 考虑颗粒间黏结力的黏性土壤离散元模型参数标定[J]. 华南农业大学学报, 2017, 38(3): 93-98. |

| WU T, HUANG W F, CHEN X S, et al. Calibration of discrete element model parameters for cohesive soil considering the cohesion between particles[J]. Journal of South China Agricultural University, 2017, 38(3): 93-98. (in Chinese with English abstract) | |

| [19] | 赵海楠. 面向窝眼轮式排种器优化的水稻种子建模方法研究[D]. 长春: 吉林大学, 2024. |

| ZHAO H N. A study on rice-seed modelling method for optimization of hole-wheel seeding metering device[D]. Changchun: Jilin University, 2024. (in Chinese with English abstract) | |

| [20] | 李辉. 水稻覆膜旱直播技术与装备研究[D]. 长春: 吉林大学, 2021. |

| LI H. Study on technology and equipment for direct-seeded rice using film mulching in dryland[D]. Changchun: Jilin University, 2021. (in Chinese with English abstract) | |

| [21] | 任甲辉, 武涛, 刘庆庭, 等. 蔗段离散元仿真建模方法与参数标定[J]. 华南农业大学学报, 2022, 43(3): 124-132. |

| REN J H, WU T, LIU Q T, et al. Discrete element simulation modeling method and parameter calibration of sugarcane segment[J]. Journal of South China Agricultural University, 2022, 43(3): 124-132. (in Chinese with English abstract) | |

| [22] | 刘宏俊, 张文毅, 纪要, 等. 基于离散元法的稻麦周年地区土壤仿真物理参数标定[J]. 中国农机化学报, 2020, 41(12): 153-159. |

| LIU H J, ZHANG W Y, JI Y, et al. Parameter calibration of soil particles in annual rice-wheat region based on discrete element method[J]. Journal of Chinese Agricultural Mechanization, 2020, 41(12): 153-159. (in Chinese with English abstract) | |

| [23] | 李勇. U型腔道式水稻精量穴播排种器设计与试验研究[D]. 合肥: 安徽农业大学, 2021. |

| LI Y. Design and experimental study of U-shaped cavity-type rice precision hole seeding device[D]. Hefei: Anhui Agricultural University, 2021. (in Chinese with English abstract) | |

| [24] | 刘春波. 水稻螺旋槽式排种器旱直播机设计与试验研究[D]. 广州: 华南农业大学, 2018. |

| LIU C B. Design and experiment of rice spiral groove type distributor drilling machine for dry land[D]. Guangzhou: South China Agricultural University, 2018. (in Chinese with English abstract) | |

| [25] | 中华人民共和国农业部. 铺膜穴播机作业质量: NY/T 987—2006[S]. 北京: 中国标准出版社, 2006. |

| [1] | 任宁, 俞国红, 郑航, 陈志东. 基于离散元法的茶园土壤参数标定[J]. 浙江农业学报, 2025, 37(6): 1353-1359. |

| [2] | 熊厚全, 江洁. 黄色赤红壤与开沟部件互作的离散元参数标定及试验[J]. 浙江农业学报, 2024, 36(6): 1400-1412. |

| [3] | 孔德, 叶自然, 谭向峰, 代梦迪, 赵先亮, 孔德栋. 生菜种子物理接触参数测定与离散元仿真标定[J]. 浙江农业学报, 2024, 36(4): 932-942. |

| [4] | 彭才望, 周婷, 孙松林, 谢烨林, 魏源. 基于堆积试验的黑水虻离散元仿真参数标定与分析[J]. 浙江农业学报, 2022, 34(4): 814-823. |

| [5] | 刘俊, 朱德泉, 于从羊, 薛康, 张顺, 廖娟. 舀勺型孔轮式水稻精量排种器设计与试验[J]. 浙江农业学报, 2021, 33(4): 739-752. |

| [6] | 王锋, 张锋伟, 戴飞, 张陆海, 赵伟, 杨小平. 双层平筛式半夏收获机设计与试验[J]. 浙江农业学报, 2021, 33(10): 1946-1955. |

| [7] | 李为宁, 柏宣丙, 李兵. 滚筒式茶叶提香机结构参数优化[J]. 浙江农业学报, 2020, 32(2): 348-358. |

| [8] | 李丽丽, 赵武云, 谭文胜, 王二化. 基于SolidWorks的天然气-柴油双燃料发动机设计与试验[J]. 浙江农业学报, 2018, 30(3): 461-469. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||