浙江农业学报 ›› 2025, Vol. 37 ›› Issue (11): 2364-2375.DOI: 10.3969/j.issn.1004-1524.20240875

基于YOLOv5-7.0草莓采摘分级机器人的设计与试验

邱琰1,2( ), 叶自然2, 谭向峰2, 代梦迪2, 葛世豪3, 阮贇杰3, 赵先亮1,*(

), 叶自然2, 谭向峰2, 代梦迪2, 葛世豪3, 阮贇杰3, 赵先亮1,*( ), 孔德栋2,*(

), 孔德栋2,*( )

)

- 1.浙江科技大学 生物与化学工程学院,浙江 杭州 310023

2.浙江省农业科学院 数字农业研究所,浙江 杭州 310021

3.浙江大学 生物系统工程与食品科学学院,浙江 杭州 310058

-

收稿日期:2024-10-12出版日期:2025-11-25发布日期:2025-12-08 -

作者简介:邱琰(1997—),男,江苏睢宁人,硕士,主要从事农业机械化自动化研究。E-mail:87359948@qq.com -

通讯作者:*赵先亮,E-mail:zlzhao@zust.edu.cn;孔德栋,E-mail: kongdd@zaas.ac.cn -

基金资助:浙江省农业科学院地方合作项目(SY202301);浙江省农业关键核心技术攻关项目

Design and experiment of strawberry picking and grading robot based on YOLOv5-7.0

QIU Yan1,2( ), YE Ziran2, TAN Xiangfeng2, DAI Mengdi2, GE Shihao3, RUAN Yunjie3, ZHAO Xianliang1,*(

), YE Ziran2, TAN Xiangfeng2, DAI Mengdi2, GE Shihao3, RUAN Yunjie3, ZHAO Xianliang1,*( ), KONG Dedong2,*(

), KONG Dedong2,*( )

)

- 1. School of Biological & Chemistry Engineering, Zhejiang University of Science and Technology, Hangzhou 310023, China

2. Institute of Digital Agriculture, Zhejiang Academy of Agricultural Sciences, Hangzhou 310021, China

3. College of Biosystems Engineering and Food Science, Zhejiang University, Hangzhou 310058, China

-

Received:2024-10-12Online:2025-11-25Published:2025-12-08

摘要:

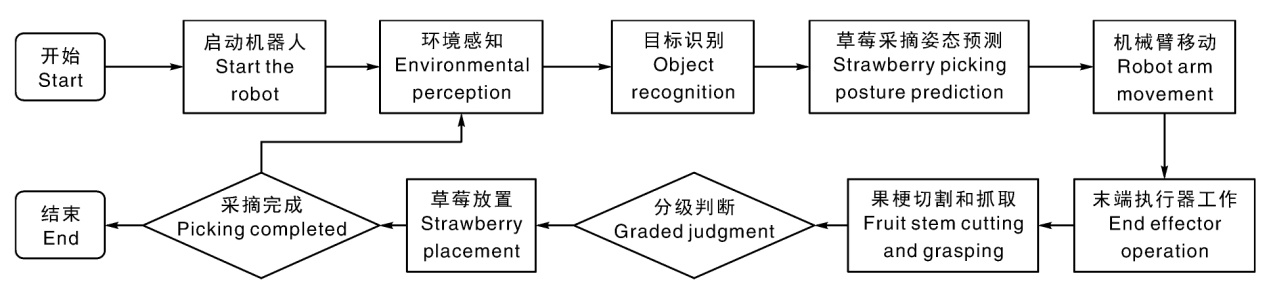

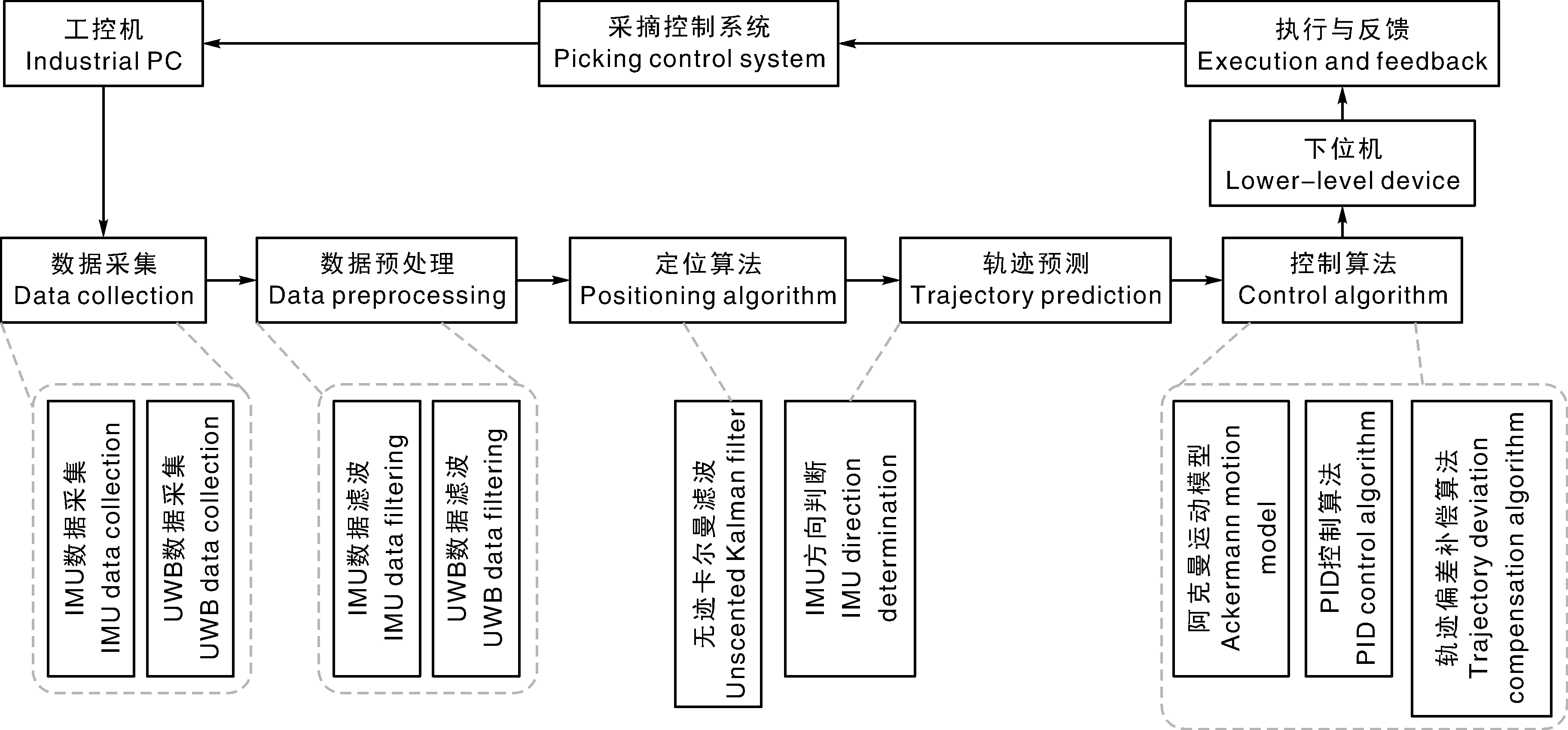

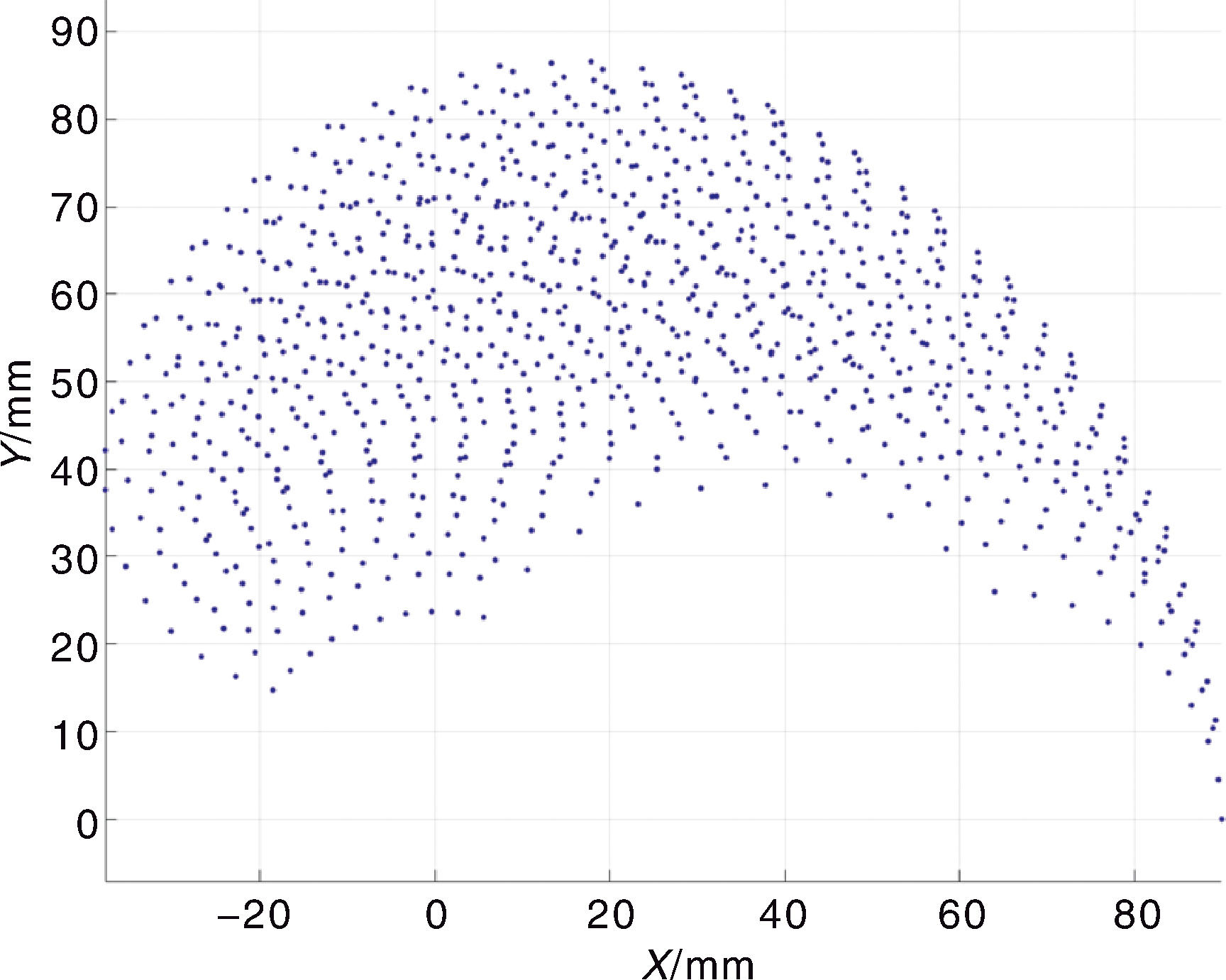

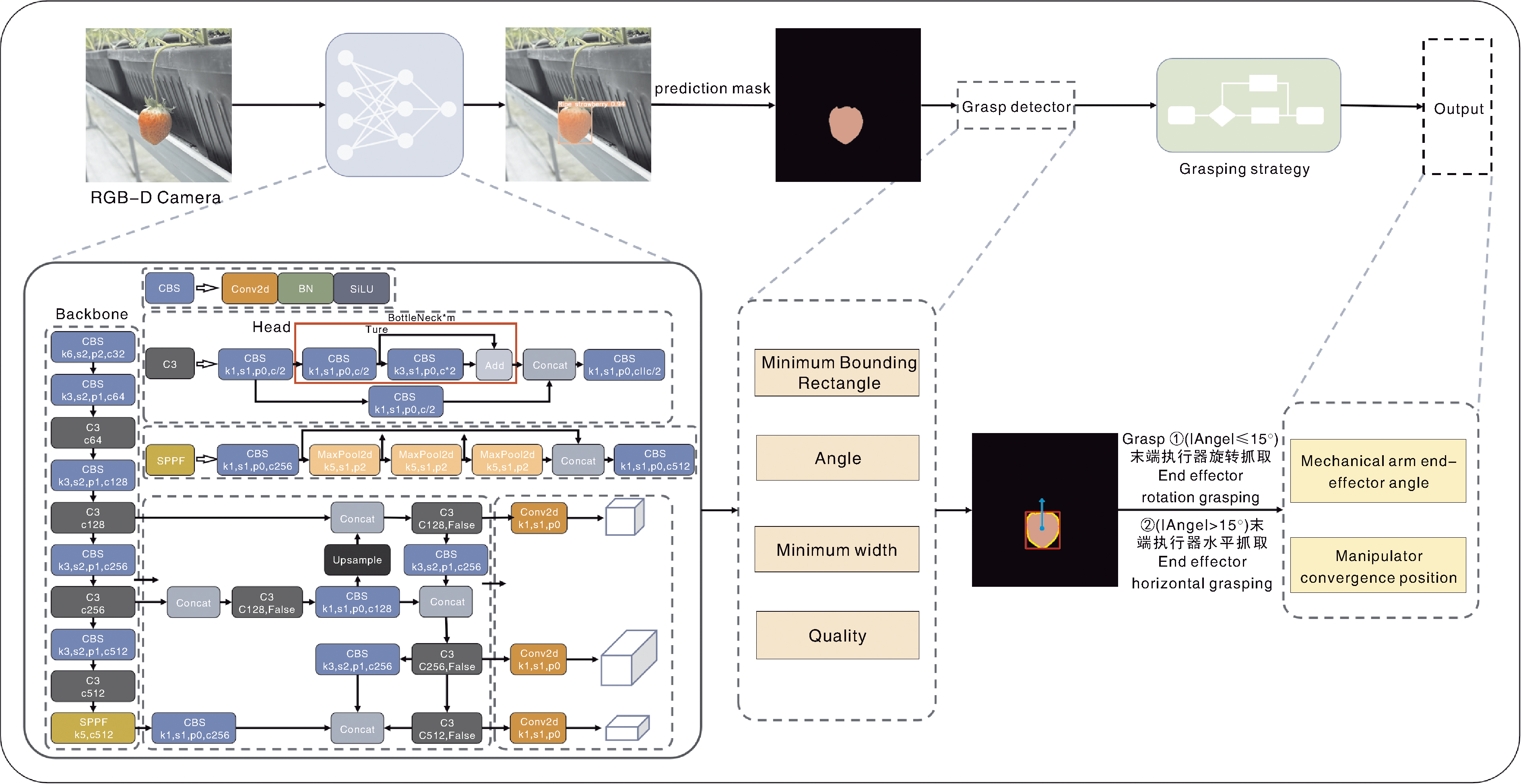

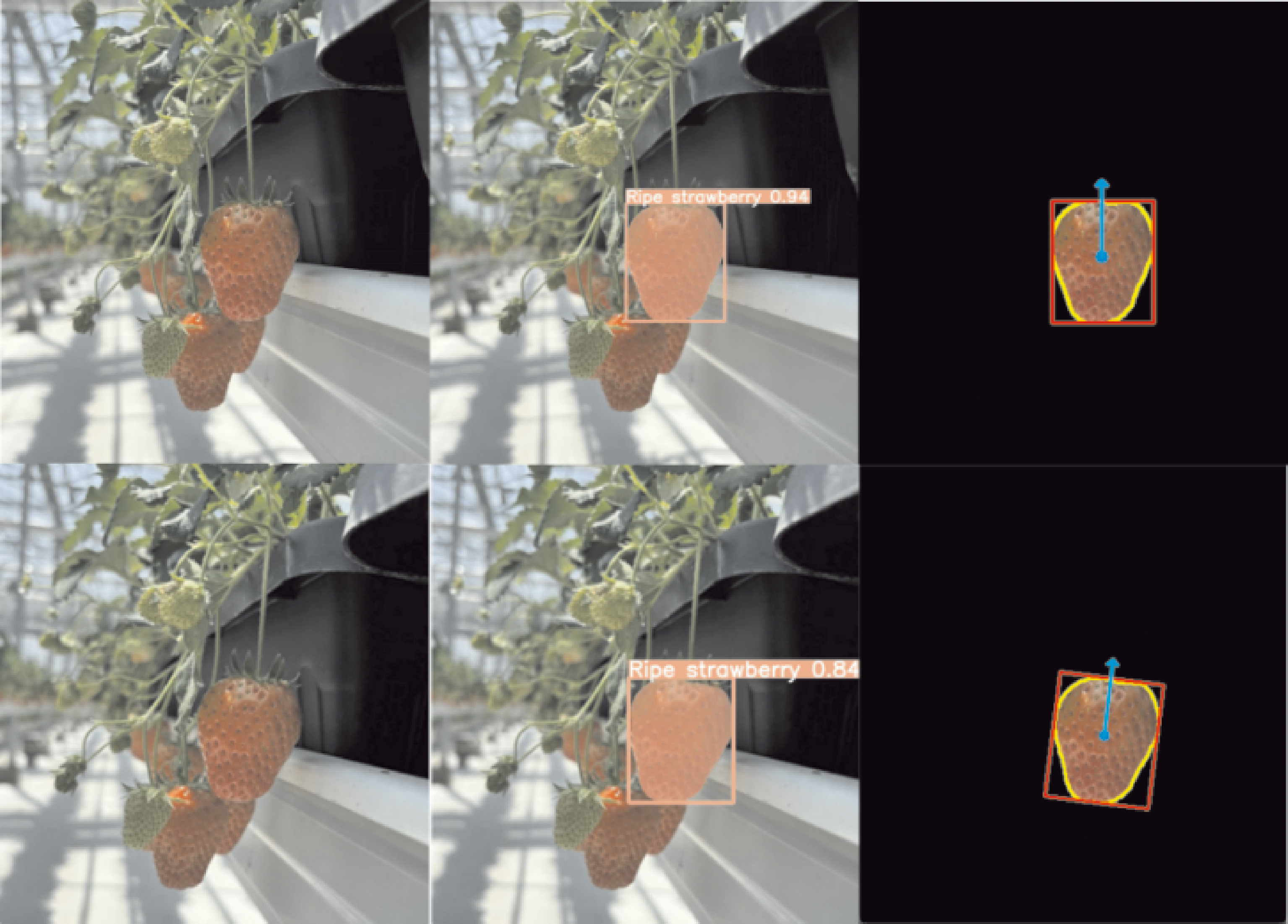

针对当前草莓植物工厂中采摘分级工作量大、人工操作难等问题,设计了一种适用于植物工厂的智能草莓采摘分级机器人。分析了整机结构及工作原理,基于理论分析与选型计算优化设计了阿克曼式底盘移动控制系统、伸缩式电动剪刀及仿人型机械手;本文利用YOLOv5-7.0算法实现了草莓分级判定与果梗生长方向预测,最后开展了整机采摘分级性能测试。试验结果表明,该机器人工作性能稳定,采摘与分级动作连贯,草莓平均分级准确率达到87.44%,实现了精准定位和轻柔抓取目标,显著提高了工作效率。

中图分类号:

引用本文

邱琰, 叶自然, 谭向峰, 代梦迪, 葛世豪, 阮贇杰, 赵先亮, 孔德栋. 基于YOLOv5-7.0草莓采摘分级机器人的设计与试验[J]. 浙江农业学报, 2025, 37(11): 2364-2375.

QIU Yan, YE Ziran, TAN Xiangfeng, DAI Mengdi, GE Shihao, RUAN Yunjie, ZHAO Xianliang, KONG Dedong. Design and experiment of strawberry picking and grading robot based on YOLOv5-7.0[J]. Acta Agriculturae Zhejiangensis, 2025, 37(11): 2364-2375.

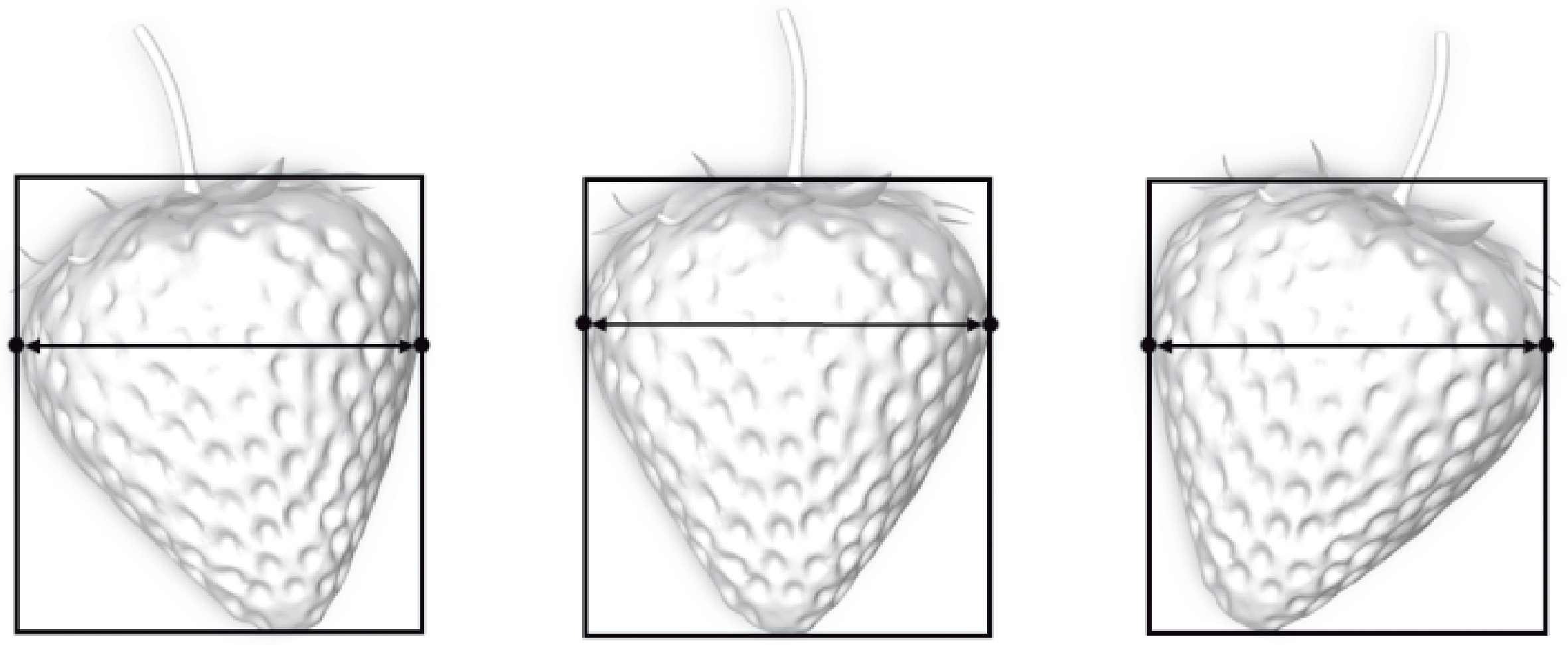

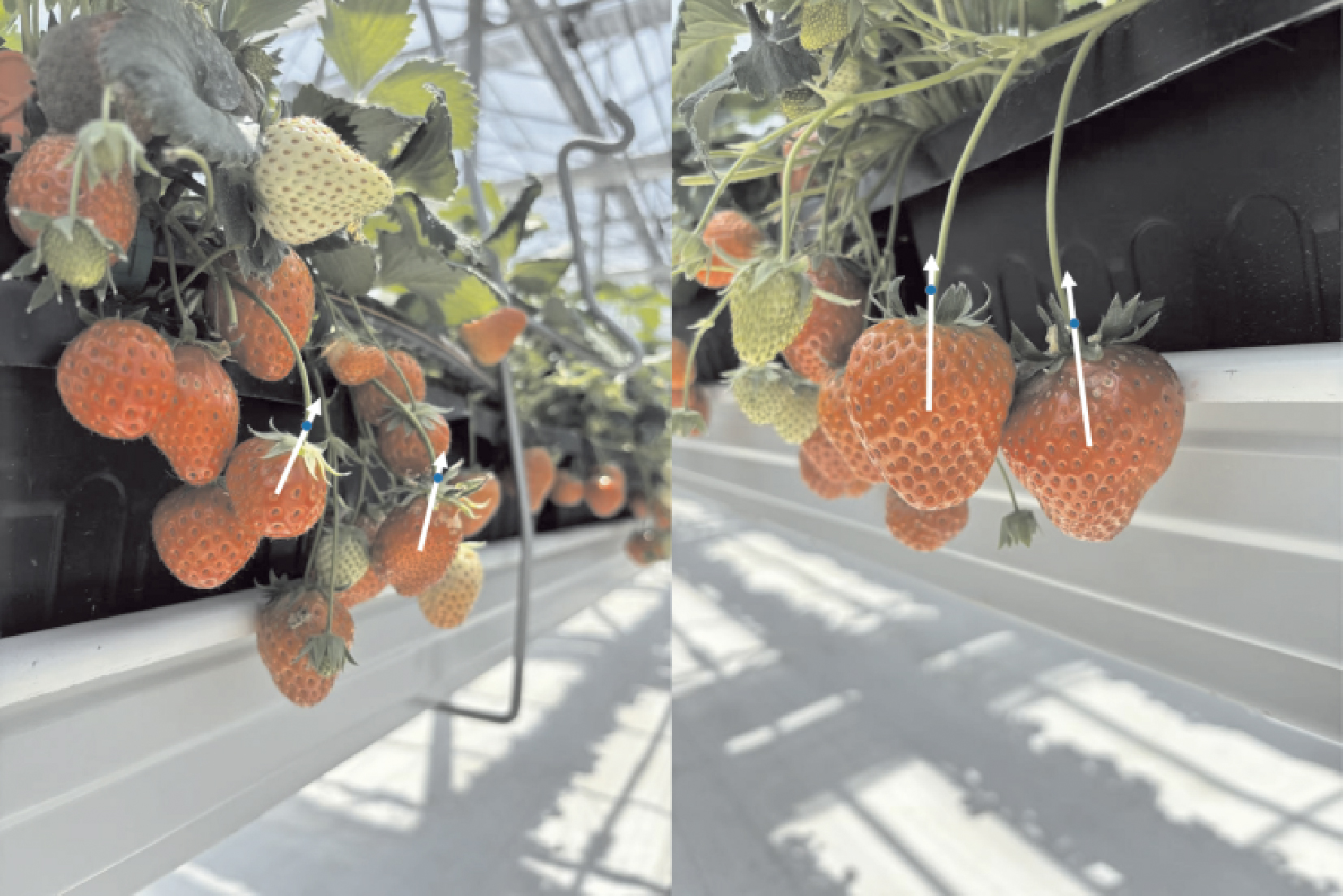

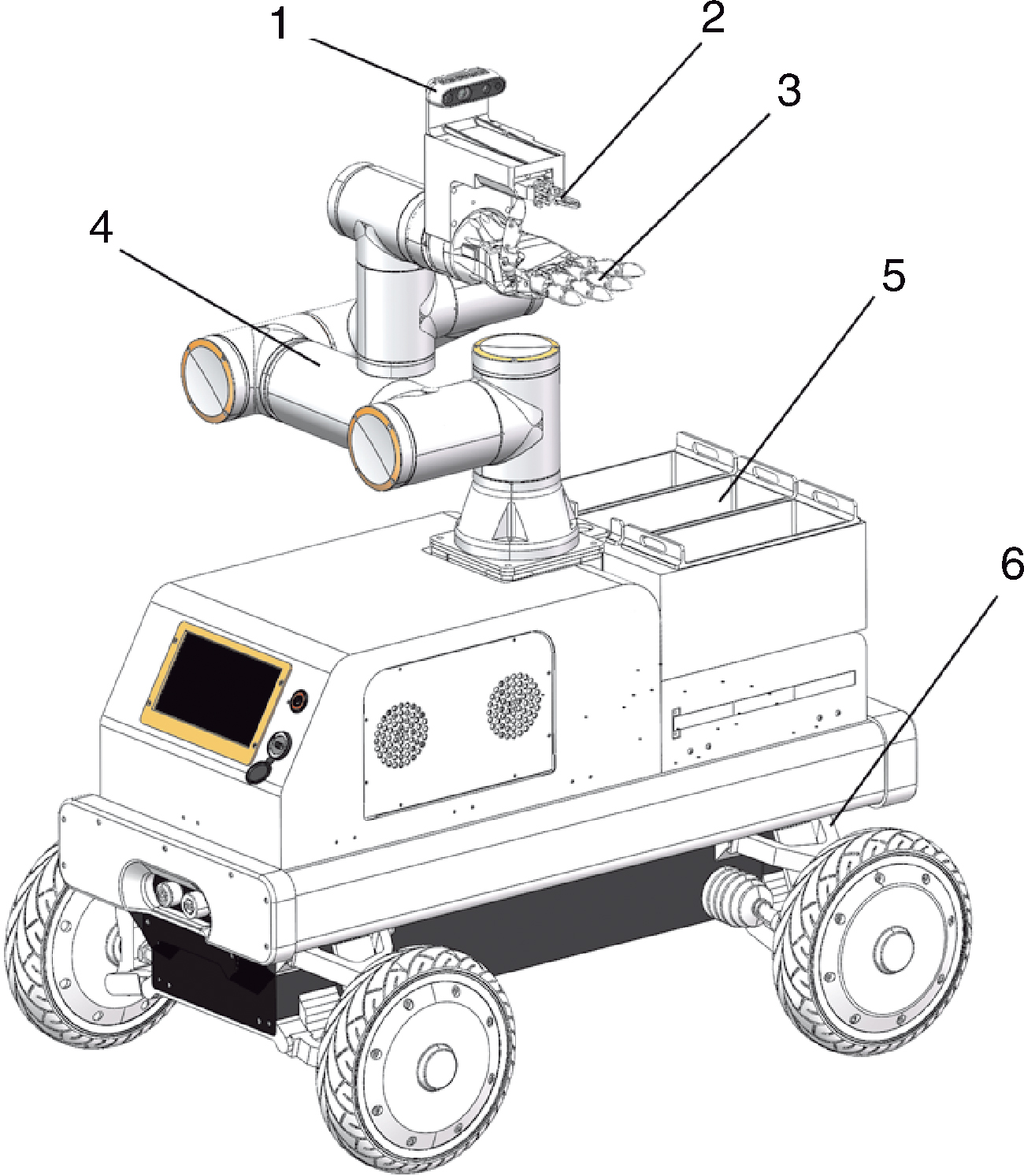

图1 草莓采摘分级机器人结构 1,深度相机RGB-D435; 2,伸缩式电动剪刀; 3,仿人型欠驱动机械手; 4,六轴机械臂;5,收集装置;6.阿克曼式底盘。

Fig.1 The structure of strawberry picking and grading robot 1, Depth camera RGB-D435; 2, Telescopic motorized scissors; 3, Humanoid underactuated manipulator; 4, 6-DOF robot arm; 5, Collection device; 6, Ackermann-type chassis.

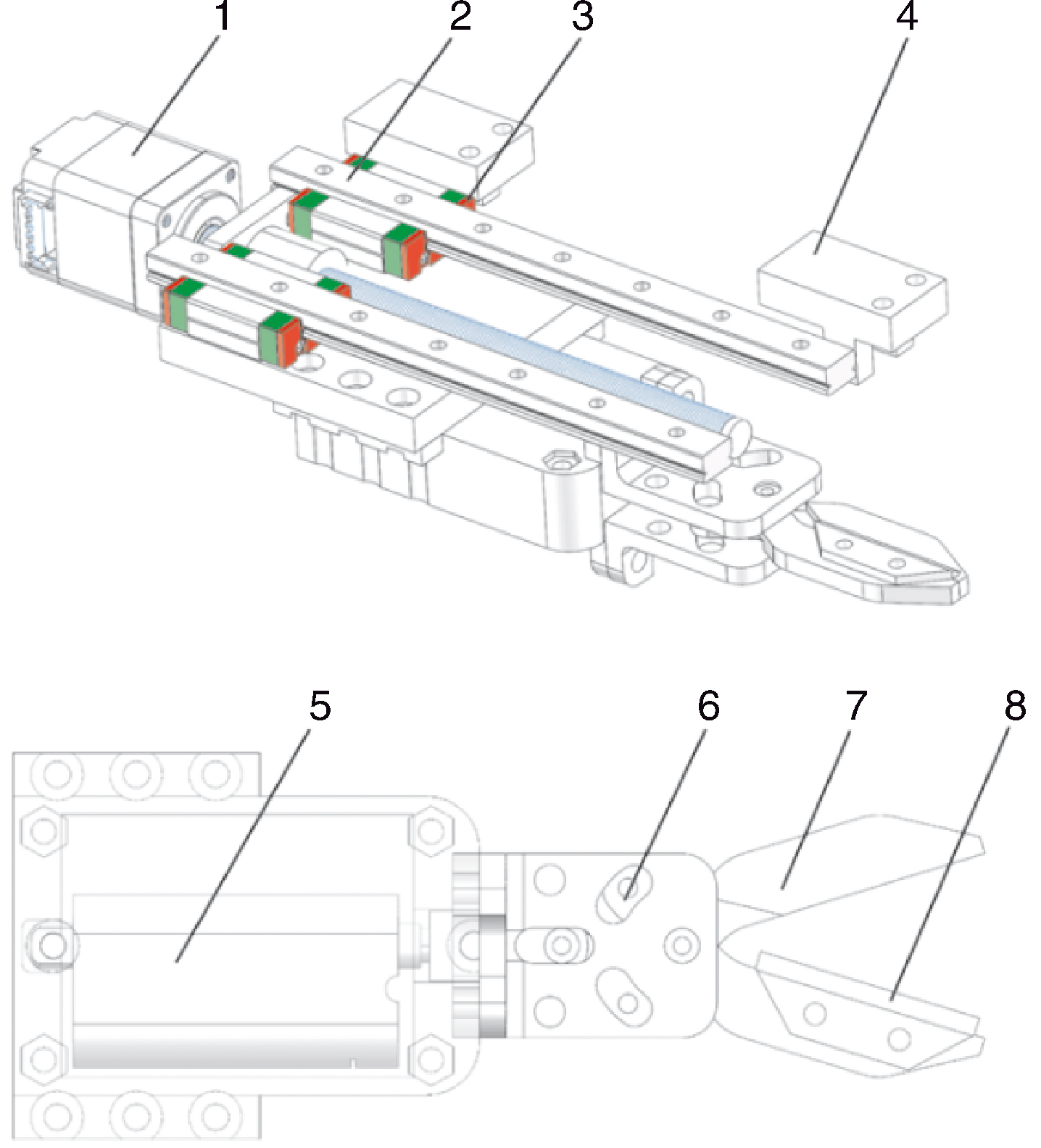

图4 伸缩式电动剪刀结构图 1,步进电机;2,滑轨;3,滑块;4,光电传感器;5,推杆电机;6,连杆;7,刀口;8,刀片。

Fig.4 The structure of retractable electric scissors 1, Stepping motor; 2, Slide rail; 3, Slider; 4, Photoelectric sensor; 5, Pusher motor; 6, Linkage; 7, Cutter; 8, Blade.

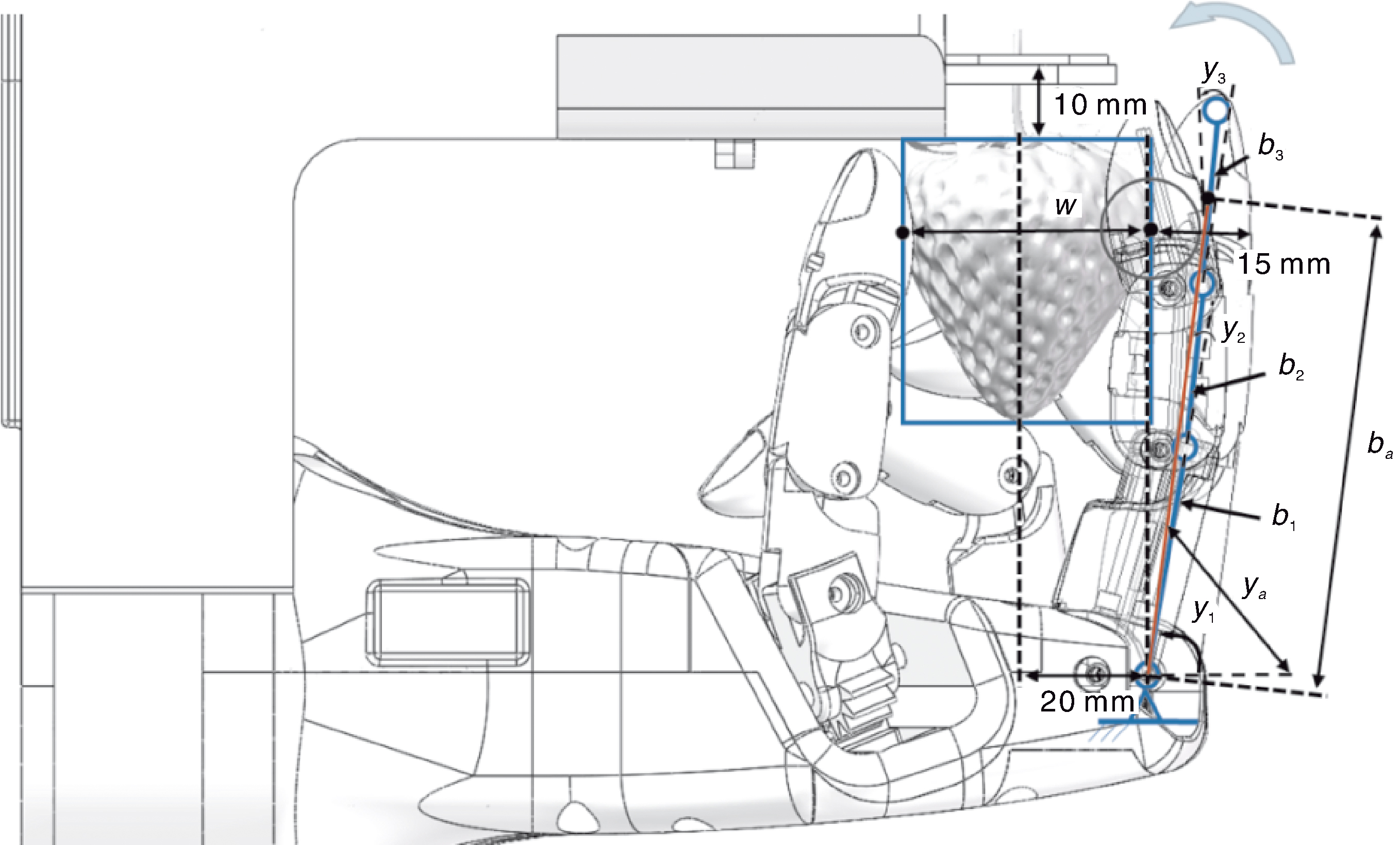

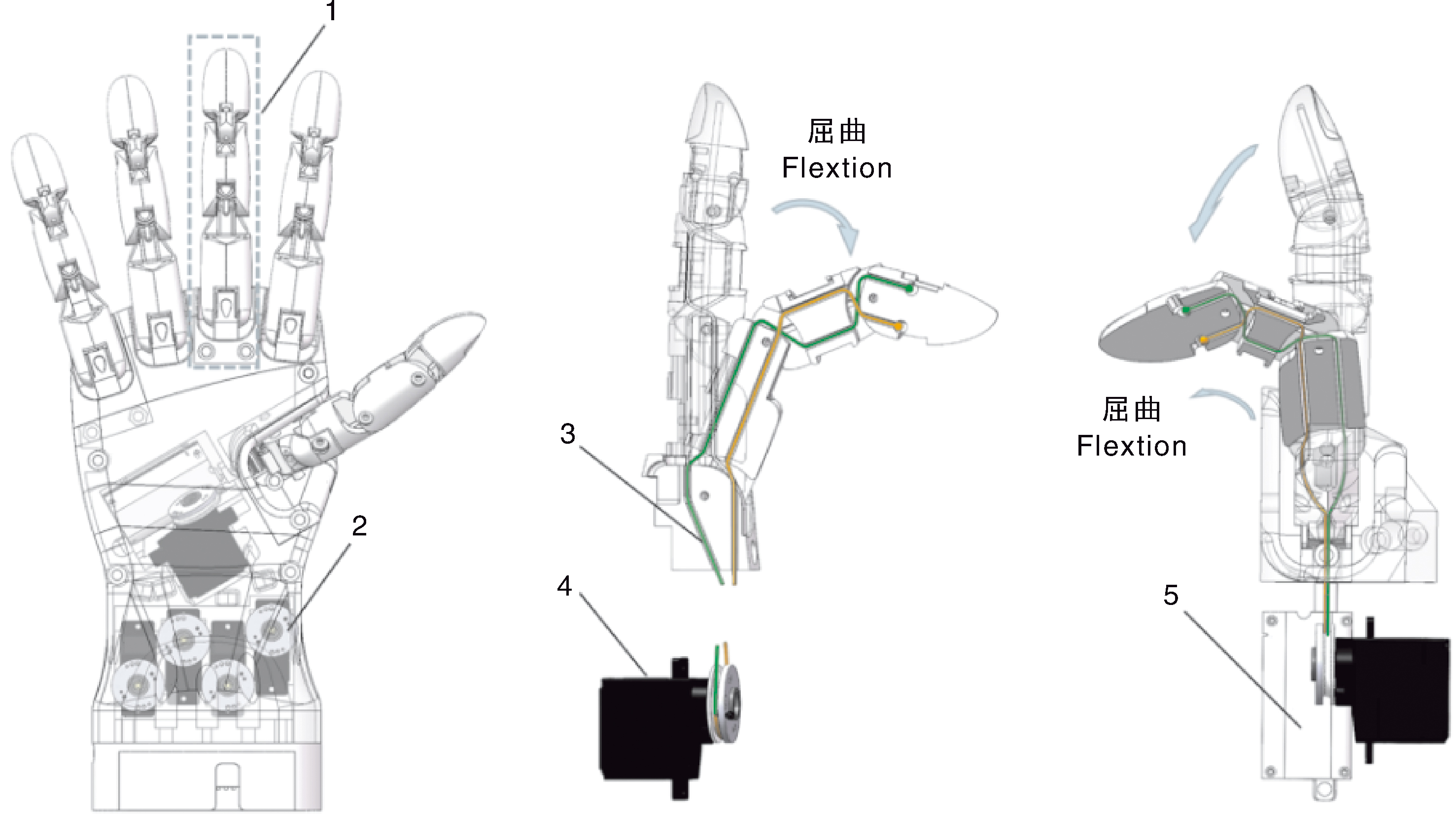

图5 仿人型欠驱机械手结构图 1,手指;2,转盘;3,绳索;4,舵机;5,推杆电机。

Fig.5 The structure of humanoid underactuated manipulator 1, Finger; 2, Turntable; 3, Rope; 4, Servo; 5, Pusher motor.

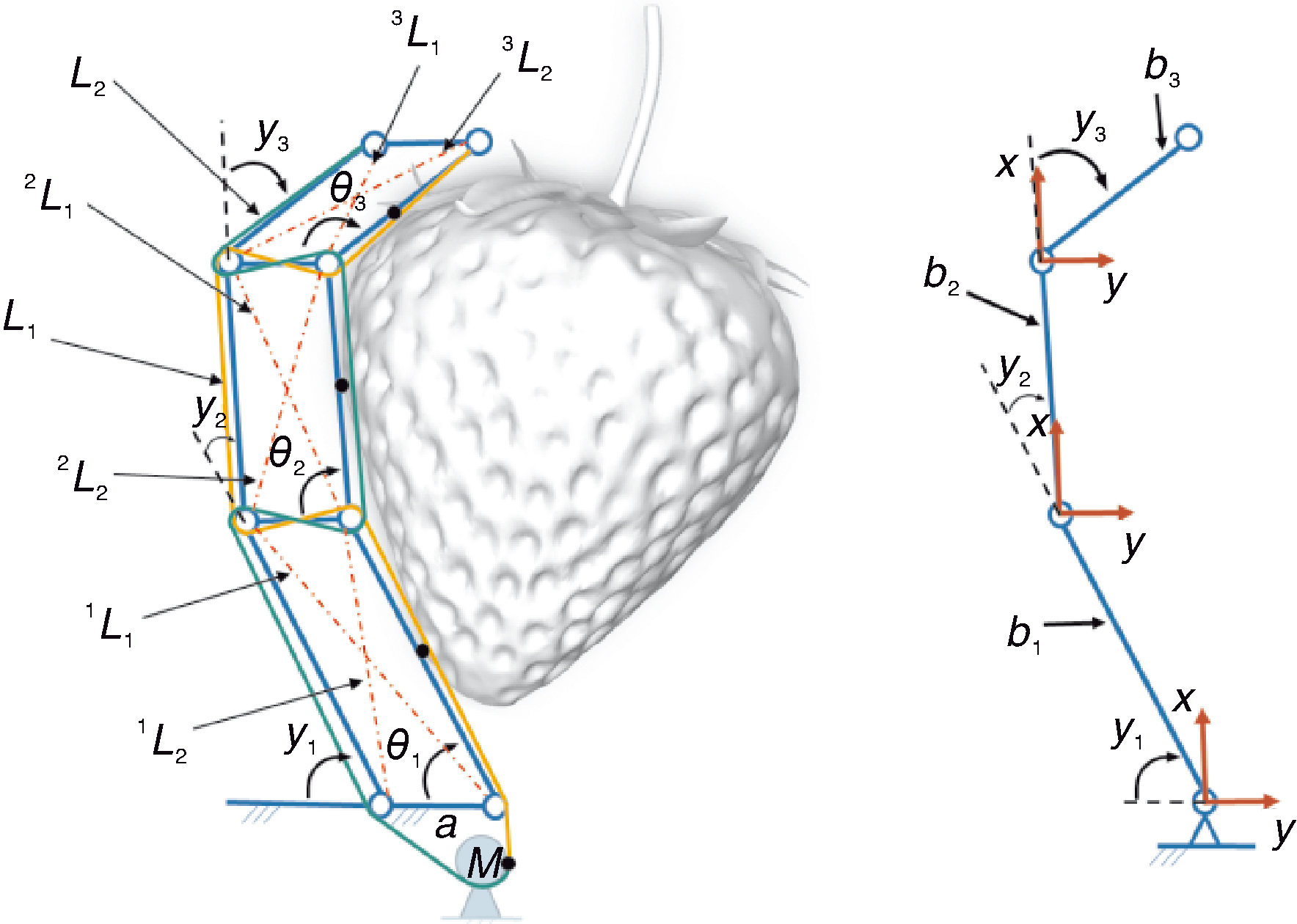

| i | ai-1/rad | bi-1/mm | di/mm | yi/rad |

|---|---|---|---|---|

| 1 | 0 | 0 | 0 | y1 |

| 2 | 0 | 36 | 0 | y2 |

| 3 | 0 | 25 | 0 | y3 |

表1 手指DH参数

Table 1 Finger DH parameters

| i | ai-1/rad | bi-1/mm | di/mm | yi/rad |

|---|---|---|---|---|

| 1 | 0 | 0 | 0 | y1 |

| 2 | 0 | 36 | 0 | y2 |

| 3 | 0 | 25 | 0 | y3 |

| 形状Shape | 判定系数K | 等级Grade |

|---|---|---|

| 圆形、纺锤形、(短)圆锥形、(短)楔形 | K>0.126 | 大Big |

| Circular, spindle-shaped, (short) conical, (short) wedge-shaped | 0.110≤K≤0.126 | 中Medium |

| K<0.110 | 小Small |

表2 草莓等级判定

Table 2 Strawberry grade judgment

| 形状Shape | 判定系数K | 等级Grade |

|---|---|---|

| 圆形、纺锤形、(短)圆锥形、(短)楔形 | K>0.126 | 大Big |

| Circular, spindle-shaped, (short) conical, (short) wedge-shaped | 0.110≤K≤0.126 | 中Medium |

| K<0.110 | 小Small |

| 分级类型 Grading type | 序号 No. | 准确率 Accuracy/% |

|---|---|---|

| 大果Big fruit | 1 | 84.21 |

| 2 | 88.00 | |

| 3 | 85.19 | |

| 中果Medium fruit | 1 | 91.70 |

| 2 | 86.96 | |

| 3 | 89.28 | |

| 小果Small fruit | 1 | 87.35 |

| 2 | 90.91 | |

| 3 | 83.33 | |

| 平均Average | 87.44 |

表3 草莓分级结果

Table 3 Strawberry grading results

| 分级类型 Grading type | 序号 No. | 准确率 Accuracy/% |

|---|---|---|

| 大果Big fruit | 1 | 84.21 |

| 2 | 88.00 | |

| 3 | 85.19 | |

| 中果Medium fruit | 1 | 91.70 |

| 2 | 86.96 | |

| 3 | 89.28 | |

| 小果Small fruit | 1 | 87.35 |

| 2 | 90.91 | |

| 3 | 83.33 | |

| 平均Average | 87.44 |

| [1] | 何娟, 肖祥飞, 郑美娟. 草莓营养品质的鉴定分析[J]. 食品安全导刊, 2023(9): 88-91. |

| HE J, XIAO X F, ZHENG M J. Identification and analysis of nutritional quality in strawberry[J]. China Food Safety Magazine, 2023(9): 88-91. (in Chinese with English abstract) | |

| [2] | GIAMPIERI F, TULIPANI S, ALVAREZ-SUAREZ J M, et al. The strawberry: composition, nutritional quality, and impact on human health[J]. Nutrition, 2012, 28(1): 9-19. |

| [3] | 刘畅, 王晓, 李宪松, 等. 我国草莓生产态势及国内外比较分析[J]. 中国果树, 2023(7): 136-140. |

| LIU C, WANG X, LI X S, et al. Strawberry production situation in China and comparative analysis at home and abroad[J]. China Fruits, 2023(7): 136-140. (in Chinese with English abstract) | |

| [4] | 余锡寿, 刘跃萍. 植物工厂中影响植物品质的因素及其控制[J]. 农业展望, 2014, 10(5): 52-55. |

| YU X S, LIU Y P. Factors of influencing plant quality and its control in plant factory[J]. Agricultural Outlook, 2014, 10(5): 52-55. (in Chinese with English abstract) | |

| [5] | 霍恒志, 糜林, 李金凤, 等. 草莓架式基质栽培与地面栽培适应性比较试验[J]. 江西农业学报, 2010, 22(11): 48-49. |

| HUO H Z, MI L, LI J F, et al. Comparative experiment on adaptability of strawberry frame substrate cultivation and ground cultivation[J]. Acta Agriculturae Jiangxi, 2010, 22(11): 48-49. (in Chinese with English abstract) | |

| [6] | VASCONEZ J P, KANTOR G A, AUAT CHEEIN F A. Human-robot interaction in agriculture: a survey and current challenges[J]. Biosystems Engineering, 2019, 179: 35-48. |

| [7] | SINGH S, VAISHNAV R, GAUTAM S, et al. Agricultural robotics: a comprehensive review of applications, challenges and future prospects[C]// 2024 2nd International Conference on Artificial Intelligence and Machine Learning Applications Theme:Healthcare and Internet of Things (AIMLA). March 15-16, 2024, Namakkal, India. IEEE, 2024: 1-8. |

| [8] | 林欢, 许林云. 中国农业机器人发展及应用现状[J]. 浙江农业学报, 2015, 27(5): 865-871. |

| LIN H, XU L Y. The development and prospect of agricultural robots in China[J]. Acta Agriculturae Zhejiangensis, 2015, 27(5): 865-871. (in Chinese with English abstract) | |

| [9] | BAO G J, YAO P F, CAI S B, et al. Flexible pneumatic end-effector for agricultural robot: Design & experiment[C]//2015 IEEE International Conference on Robotics and Biomimetics (ROBIO). December 6-9, 2015, Zhuhai, China. IEEE, 2015: 2175-2180. |

| [10] | 李娜, 王家忠, 张建宝, 等. 一种刚柔混联欠驱动草莓采摘机械手设计[J]. 河北农业大学学报, 2015, 38(1): 118-121. |

| LI N, WANG J Z, ZHANG J B, et al. Design of underactuated strawberry harvesting manipulator with rigid-compliant structured[J]. Journal of Agricultural University of Hebei, 2015, 38(1): 118-121. (in Chinese with English abstract) | |

| [11] | LI Z G, MIAO F L, YANG Z B, et al. Factors affecting human hand grasp type in tomato fruit-picking: a statistical investigation for ergonomic development of harvesting robot[J]. Computers and Electronics in Agriculture, 2019, 157: 90-97. |

| [12] | WANG J N, LI B X, LI Z G, et al. Grasping behavior of the human hand during tomato picking[J]. Computers and Electronics in Agriculture, 2021, 180: 105901. |

| [13] | 李鑫. 用于机器采摘的高架草莓识别与分级方法的研究[D]. 南京: 东南大学, 2018. |

| LI X. A recognition and grading method for machine picking of elevated strawberries[D]. Nanjing: Southeast University, 2018. (in Chinese with English abstract) | |

| [14] | 张樱飘. 基于深度学习的草莓采摘机器人果实识别定位与采后自动分级技术研究[D]. 天津: 天津理工大学, 2023. |

| ZHANG Y P. Study on fruit recognition and location and post-harvest automatic grading technology of strawberry picking robot based on deep learning[D]. Tianjin: Tianjin University of Technology, 2023. (in Chinese with English abstract) | |

| [15] | 刘建军, 姚立健, 彭樟林. 基于机器视觉的山核桃等级检测技术[J]. 浙江农业学报, 2010, 22(6): 854-858. |

| LIU J J, YAO L J, PENG Z L. Detection technique for Cathay hickory grade based on machine vision[J]. Acta Agriculturae Zhejiangensis, 2010, 22(6): 854-858. (in Chinese with English abstract) | |

| [16] | 姚立健, 边起, 雷良育, 等. 基于BP神经网络的水果分级研究[J]. 浙江农业学报, 2012, 24(5): 926-930. |

| YAO L J, BIAN Q, LEI L Y, et al. Classification of fruit based on the BP neural network[J]. Acta Agriculturae Zhejiangensis, 2012, 24(5): 926-930. (in Chinese with English abstract) | |

| [17] | 谭兴龙, 韩宇. 非视距环境下顾及杆臂补偿的UWB/IMU定位算法[J]. 中国惯性技术学报, 2024, 32(8): 762-770. |

| TAN X L, HAN Y. UWB/IMU positioning algorithm considering lever arm compensation in non-line-of-sight environment[J]. Journal of Chinese Inertial Technology, 2024, 32(8): 762-770. (in Chinese with English abstract) | |

| [18] | 李延平, 刘杰, 苏焱鸿, 等. 基于UWB的室内物料搬运机器人设计[J]. 机电技术, 2024, 47(4): 73-78. |

| LI Y P, LIU J, SU Y H, et al. Design of indoor material handling robot based on UWB[J]. Mechanical & Electrical Technology, 2024, 47(4): 73-78. (in Chinese with English abstract) | |

| [19] | 周增产, 赵静, 胡福生, 等. 草莓集装箱植物工厂设计与应用[J]. 农业工程, 2020, 10(9): 52-57. |

| ZHOU Z C, ZHAO J, HU F S, et al. Design and application of strawberry container plant factory[J]. Agricultural Engineering, 2020, 10(9): 52-57. (in Chinese with English abstract) | |

| [20] | MAO B J, ZHOU K Y, XIANG Y, et al. A bioinspired robotic finger for multimodal tactile sensing powered by fiber optic sensors[J]. Advanced Intelligent Systems, 2024, 6(8): 2400175. |

| [21] | BELTER J T, SEGIL J L, DOLLAR A M, et al. Mechanical design and performance specifications of anthropomorphic prosthetic hands: a review[J]. The Journal of Rehabilitation Research and Development, 2013, 50(5): 599. |

| [22] | XIONG C H, CHEN W R, SUN B Y, et al. Design and implementation of an anthropomorphic hand for replicating human grasping functions[J]. IEEE Transactions on Robotics, 2016, 32(3): 652-671. |

| [23] | CONTROZZI M, CLEMENTE F, BARONE D, et al. The SSSA-MyHand: a dexterous lightweight myoelectric hand prosthesis[J]. IEEE Transactions on Neural Systems and Rehabilitation Engineering, 2017, 25(5): 459-468. |

| [24] | 张琛. 基于机器视觉的苹果外观品质分级系统研究[D]. 青岛: 山东科技大学, 2020. |

| ZHANG C. Research on apple appearance quality grading system based on machine vision[D]. Qingdao: Shandong University of Science and Technology, 2020. (in Chinese with English abstract) | |

| [25] | 任潇, 朱孟东, 武宁, 等. 我国草莓等级规格标准比对分析研究[J]. 农产品质量与安全, 2023(1): 39-45. |

| REN X, ZHU M D, WU N, et al. Comparative analysis of strawberry grade and specification standards in China[J]. Quality and Safety of Agro-Products, 2023(1): 39-45. (in Chinese with English abstract) | |

| [26] | 覃磊, 孙开琼, 李诗高, 等. 基于RGB颜色相似度的成熟草莓图像分割[J]. 浙江农业学报, 2016, 28(2): 330-337. |

| QIN L, SUN K Q, LI S G, et al. Image segmentation of ripe strawberry based on RGB color similarity[J]. Acta Agriculturae Zhejiangensis, 2016, 28(2): 330-337. (in Chinese with English abstract) |

| [1] | 陈巍, 王荣荣, 蒋雯静, 耿伟淞, 陈岑. 壳聚糖-壳寡糖复合膜的制备及其在草莓保鲜中的应用[J]. 浙江农业学报, 2025, 37(8): 1785-1793. |

| [2] | 沈岚, 杨肖芳, 张国芳. 草莓根腐病病原菌的鉴定及其对杀菌剂的敏感性[J]. 浙江农业学报, 2025, 37(2): 417-425. |

| [3] | 俞国红, 郑航, 叶云翔, 薛向磊, 傅童. 轻便自走式采茶机的设计与试验[J]. 浙江农业学报, 2023, 35(9): 2233-2239. |

| [4] | 张馨月, 杨禹诚, 段皓月, 周杨洁, 黄嘉杨, 陈梓月, 蒋洁, 陈姝娟. 氮掺杂碳量子点-壳聚糖复合膜的制备及对草莓的保鲜效果[J]. 浙江农业学报, 2023, 35(12): 2935-2943. |

| [5] | 向淅, 王思悦, 蒲俊宏, 唐雯璐, 陈清. 低温短日照诱导五叶草莓成花诱导的机理研究[J]. 浙江农业学报, 2022, 34(8): 1661-1668. |

| [6] | 杨肖芳, 李云端, 孙云帆, 李绍佳, 苗立祥, 张豫超, 蒋桂华. 基质栽培与土壤栽培对越心草莓蔗糖和柠檬酸积累的影响[J]. 浙江农业学报, 2022, 34(7): 1423-1430. |

| [7] | 李赞松, 曹成茂, 伍德林, 张建宇. 手自一体式山核桃采摘机的设计与试验[J]. 浙江农业学报, 2021, 33(7): 1309-1319. |

| [8] | 李清斌, 秦奔奔, 李盈盈, 范凯锋, 杨栋, 陈磊, 刘鹍. 连阴雨寡日照对大棚草莓小气候、产量和品质的影响[J]. 浙江农业学报, 2021, 33(5): 831-839. |

| [9] | 孙达, 龚恕, 崔宏春, 郭敏明, 郑旭霞. 不同品种茶树春秋季鲜叶超微绿茶粉适制性研究[J]. 浙江农业学报, 2021, 33(3): 437-446. |

| [10] | 冯江鹏, 邱莉萍, 梁秀燕, 陈碧秀, 夏海洋, 彭春龙, 钟永军. 草莓胶孢炭疽菌拮抗细菌贝莱斯芽孢杆菌JK3的鉴定及其抗菌活性[J]. 浙江农业学报, 2020, 32(5): 831-839. |

| [11] | 裘劼人, 柴伟国, 童建新, 周历萍, 王淑珍. 质谱蛋白质组学研究中草莓雌蕊蛋白提取方法优化[J]. 浙江农业学报, 2020, 32(12): 2186-2191. |

| [12] | 王淑珍, 周历萍, 裘劼人, 童建新, 余红, 柴伟国, 来文国. 草莓种间杂交后代与亲本性状比较[J]. 浙江农业学报, 2020, 32(10): 1780-1787. |

| [13] | 王淑珍, 张亚惠, 裘劼人, 周历萍, 陈思思, 柴伟国, 毛碧增. 不同倍性草莓品种性状比较[J]. 浙江农业学报, 2019, 31(6): 893-899. |

| [14] | 辛松林, 向泽攀, 亢小勤, 肖川, 秦文. 采摘期对川秋葵木质素代谢及相关酶活性的影响[J]. 浙江农业学报, 2018, 30(9): 1519-1525. |

| [15] | 马义胜, 洪春来, 王卫平, 姚燕来, 朱凤香, 陈晓旸, 薛智勇. 铁皮石斛栽培废料和菇渣配制基质对草莓生长、产量及品质的影响[J]. 浙江农业学报, 2018, 30(7): 1175-1181. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||